Calcium magnesium silico-phosphate cement and processing method of same

A calcium phosphate, silicon magnesium technology, applied in the field of building materials, can solve problems such as consumption of large mineral resources and poor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

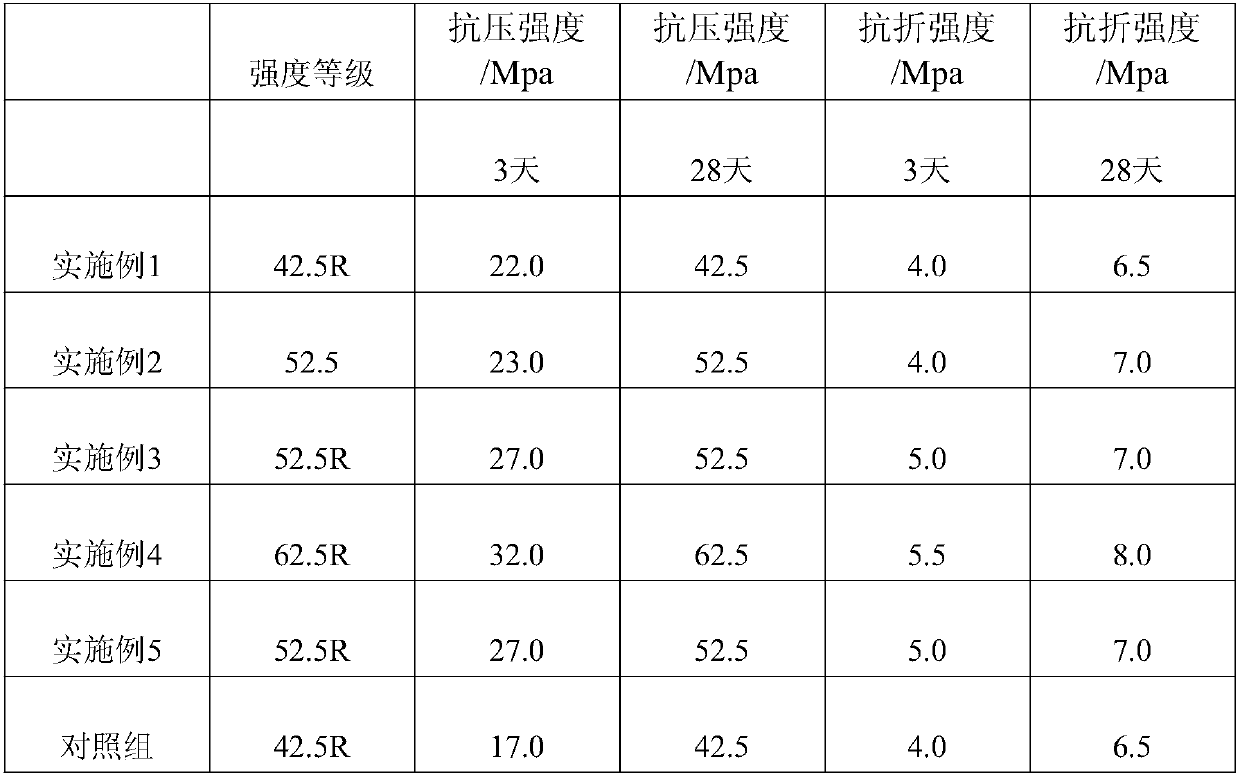

Examples

Embodiment 1

[0021] A calcium silicate magnesium phosphate cement, comprising the following raw materials in parts by mass: 120 kg of diammonium phosphate, 70 kg of magnesium oxide, 50 kg of fly ash, 3 kg of borax, 2 kg of potassium dihydrogen phosphate, and 1 kg of sodium hexametaphosphate.

[0022] Described diammonium phosphate has a nutrient content of 45%.

[0023] The magnesium oxide is obtained by calcining the raw materials at 300°C for 3 hours, at 700°C for 7 hours, at 950°C for 10 hours, and at 600°C for 6 hours.

[0024] Described calcium silicate magnesium cement, comprises following preparation method:

[0025] 1) Grind magnesium oxide, borax and fly ash to 200, potassium dihydrogen phosphate, sodium hexametaphosphate and diammonium phosphate to 100;

[0026] 2) Put the uniformly stirred mixture into a drier to dry to obtain calcium-silicon-magnesium phosphate cement.

[0027] The drying is at 140°C for 3 hours, at 90°C for 7 hours, and at 60°C for 6 hours.

Embodiment 2

[0029] A calcium silicate magnesium phosphate cement, comprising the following raw materials in parts by mass: 130 kg of diammonium phosphate, 80 kg of magnesium oxide, 60 kg of fly ash, 4 kg of borax, 3 kg of potassium dihydrogen phosphate, and 1.5 kg of sodium hexametaphosphate.

[0030] Described diammonium phosphate has a nutrient content of 50%.

[0031] The magnesium oxide is obtained by calcining the raw materials at 310°C for 3.5 hours, at 710°C for 7.6 hours, at 970°C for 11 hours, and at 610°C for 6.5 hours.

[0032] Described calcium silicate magnesium cement, comprises following preparation method:

[0033] 1) Grinding magnesium oxide, borax and fly ash to 230 mesh, potassium dihydrogen phosphate, sodium hexametaphosphate and diammonium phosphate to 120 mesh;

[0034] 2) Put the uniformly stirred mixture into a drier to dry to obtain calcium-silicon-magnesium phosphate cement.

[0035] The drying is at 145°C for 3.5 hours, at 100°C for 7.5 hours, and at 70°C for ...

Embodiment 3

[0037] A calcium silicate magnesium phosphate cement, comprising the following raw materials in parts by mass: 140 kg of diammonium phosphate, 85 kg of magnesium oxide, 65 kg of fly ash, 5 kg of borax, 3.5 kg of potassium dihydrogen phosphate, and 2.5 kg of sodium hexametaphosphate.

[0038] Described diammonium phosphate has a nutrient content of 60%.

[0039] The magnesium oxide is obtained by calcining the raw materials at 320°C for 4 hours, at 720°C for 8 hours, at 970°C for 135 hours, and at 630°C for 7 hours.

[0040] Described calcium silicate magnesium cement, comprises following preparation method:

[0041] 1) Grinding magnesium oxide, borax and fly ash to 300 mesh, potassium dihydrogen phosphate, sodium hexametaphosphate and diammonium phosphate to 140 mesh;

[0042] 2) Put the uniformly stirred mixture into a drier to dry to obtain calcium-silicon-magnesium phosphate cement.

[0043] The drying is at 148°C for 4.5 hours, at 105°C for 9 hours, and at 75°C for 7 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com