Method for calculating critical discharge of horizontal well cement slurry

A technology of cementing slurry and calculation method, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problem of falling, not conforming to the real rheology of cement slurry used in the field, error cementing quality, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

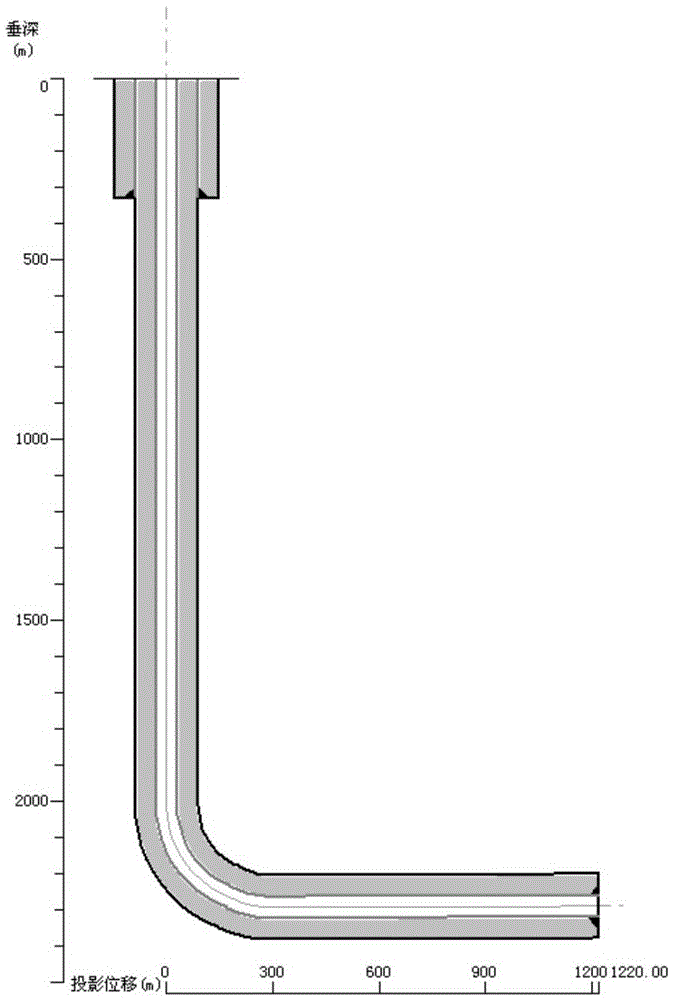

[0040] Taking Well HH36P114 in Honghe Oilfield of North China Branch Company as an example, the basic conditions of the well are as follows: the first drill was drilled to 372m with a Ф311.2mm drill bit, and the Ф244.5mm surface casing was lowered to 371.80m for cementing, and the second drill was drilled with a Ф215.9mm The drill bit was drilled to 3408m and the drilling was completed, and the Ф139.7mm oil layer casing was lowered to 3405m (see the actual drilling body structure diagram figure 1 ).

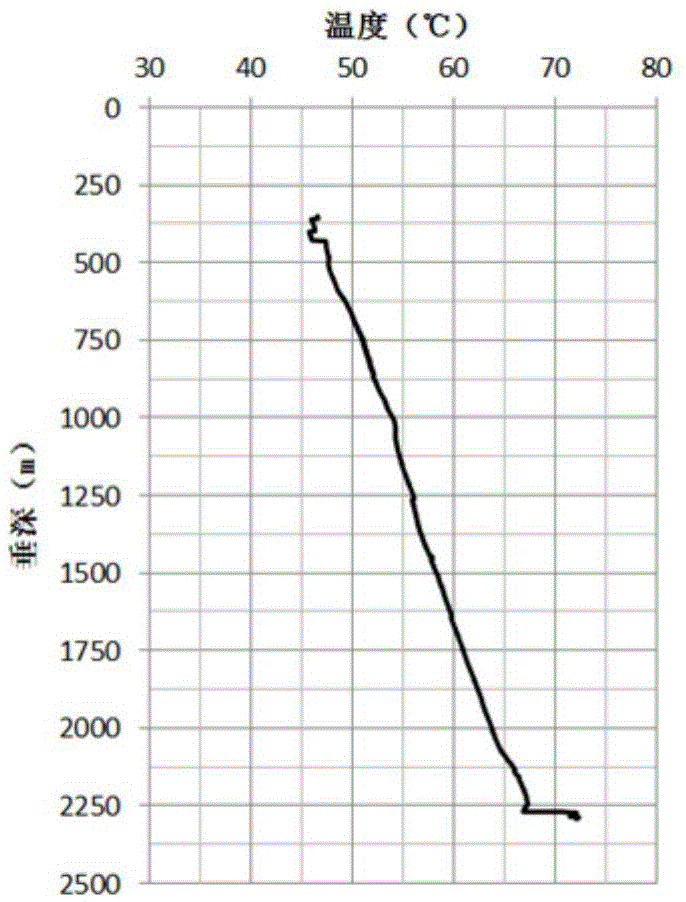

[0041] The calculation method for the critical displacement of cement slurry in Well HH36P114 in Honghe Oilfield includes the following steps:

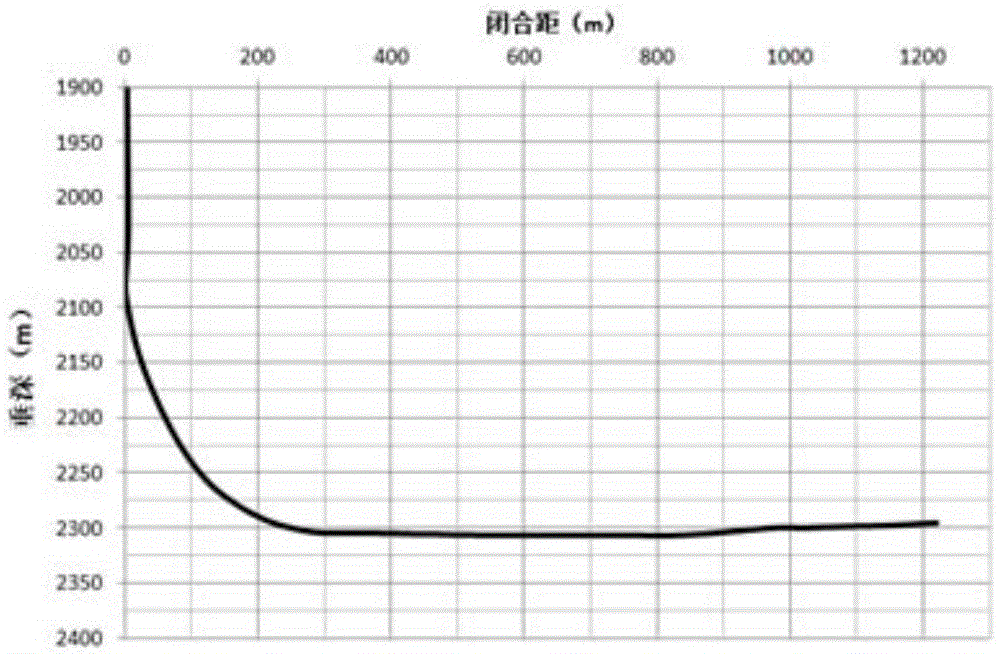

[0042] (1) The wellbore trajectory is measured with the WMD trajectory measurement tool. Through measurement and calculation, the bottom of the well has a vertical depth of 2295.44m, a horizontal displacement of 1220m, and a horizontal section length of 920m (see the vertical profile of the actual drilling trajectory in figure 2 );

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com