An easy-to-drill anti-rotation fracturing bridge plug

A fracturing and anti-rotation technology, which can be used in earth-moving drilling, wellbore/well components, sealing/packaging, etc. Sex, the effect of preventing up and down movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

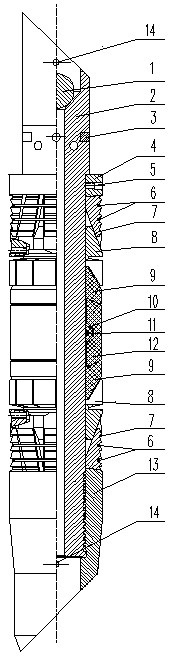

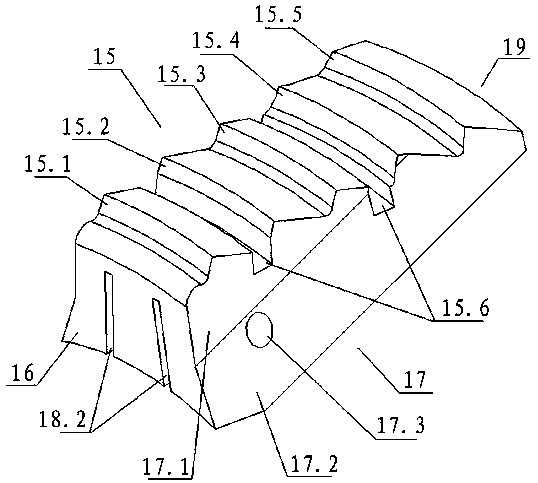

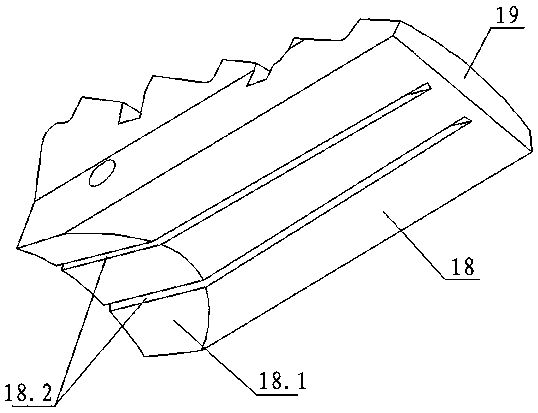

[0024] This embodiment provides an easy-to-drill anti-rotation fracturing plug, such as figure 1 As shown, it includes the center tube 2 and the slip stop ring 4 set on the outer wall of the center tube 2, the slip 7 embedded in the cone, the cone back ring 8, the end rubber sleeve 9, the middle rubber sleeve 12 (including the bearing retaining ring 10 and O-ring 11), guide shoe 13 (including guide shoe insertion rod 14) and the fracturing resin ball 1 in the central tube 2, the slips 7 have 8 pieces, and are uniform along the inner circumference of the casing distribution, the circumference of the cone back ring 8 is evenly provided with 8 dovetail grooves compatible with the aforementioned 8 slips 7, and the aforementioned 8 slips 7 are composed of 2 snap rings 6 arranged in parallel along the inner circumference of the casing. Tighten the assembly. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com