Visual sand blasting model used for oil displacement experiment and manufacturing method thereof

A sandblasting and experimental technology, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of easy channeling on the surface and difficulty in controlling the permeability of glass or plexiglass plate models, so as to avoid difficult control and inhomogeneity, the effect of uniform porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described further below:

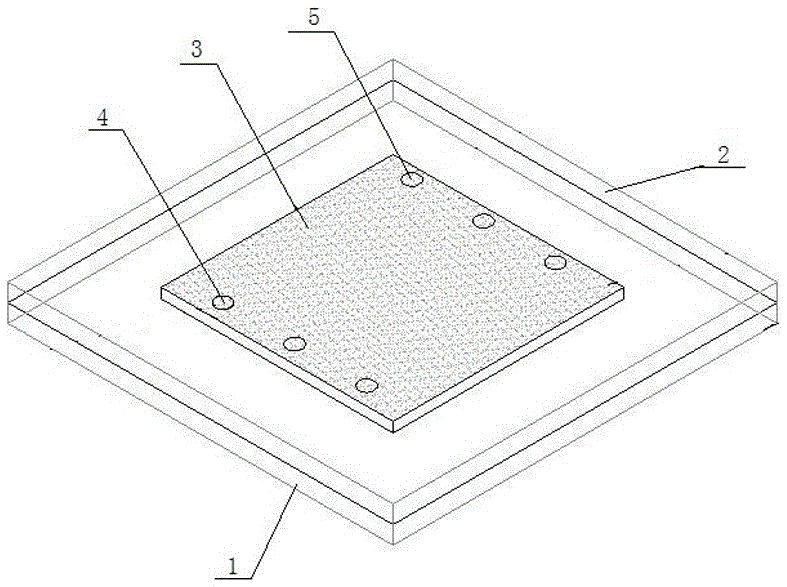

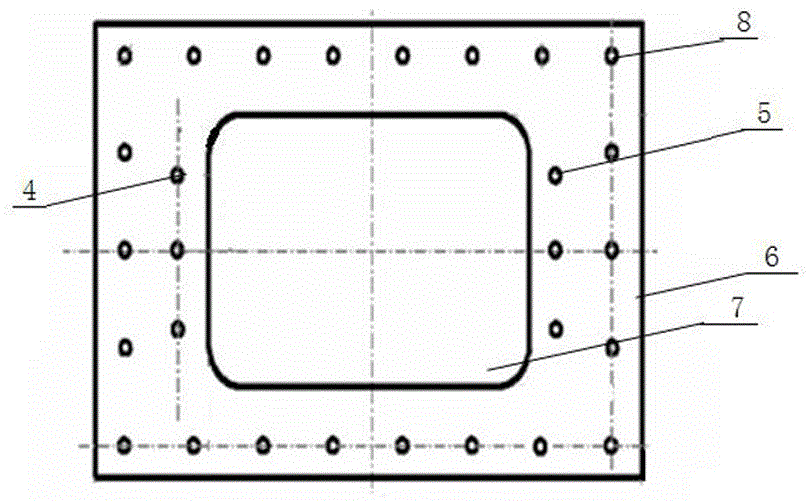

[0030] Such as figure 1 As shown, this visual sandblasting model for oil displacement experiments includes a glass slide 1 and a glass cover slide 2. The center of the inner surface of the glass slide 1 is provided with a square groove for accommodating a cemented layer of quartz sand. Layer 3 adopts compressed air to carry the cementing agent and quartz sand, and sprays it with high-speed gas in the square groove in the glass slide 1. The thickness of the quartz sand cement layer 3 is the same as the depth of the square groove in the glass slide 1; the glass cover 2 The size is the same as that of the glass slide 1, and the glass cover 2 and the glass slide 1 are bonded and formed by silicone sealant; the injection and production port designed according to the well pattern runs through the glass cover 2 and the quartz sand cement layer 3, and the injection and production port It is connected with the indoor injection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com