Turbine blade scaling cleaning device and cleaning method thereof

A technology for steam turbine blades and cleaning devices, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as potential safety hazards, harsh working environments, and high labor intensity, and reduce maintenance labor Strength, reduce spare parts consumption, and eliminate potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in combination with specific embodiments.

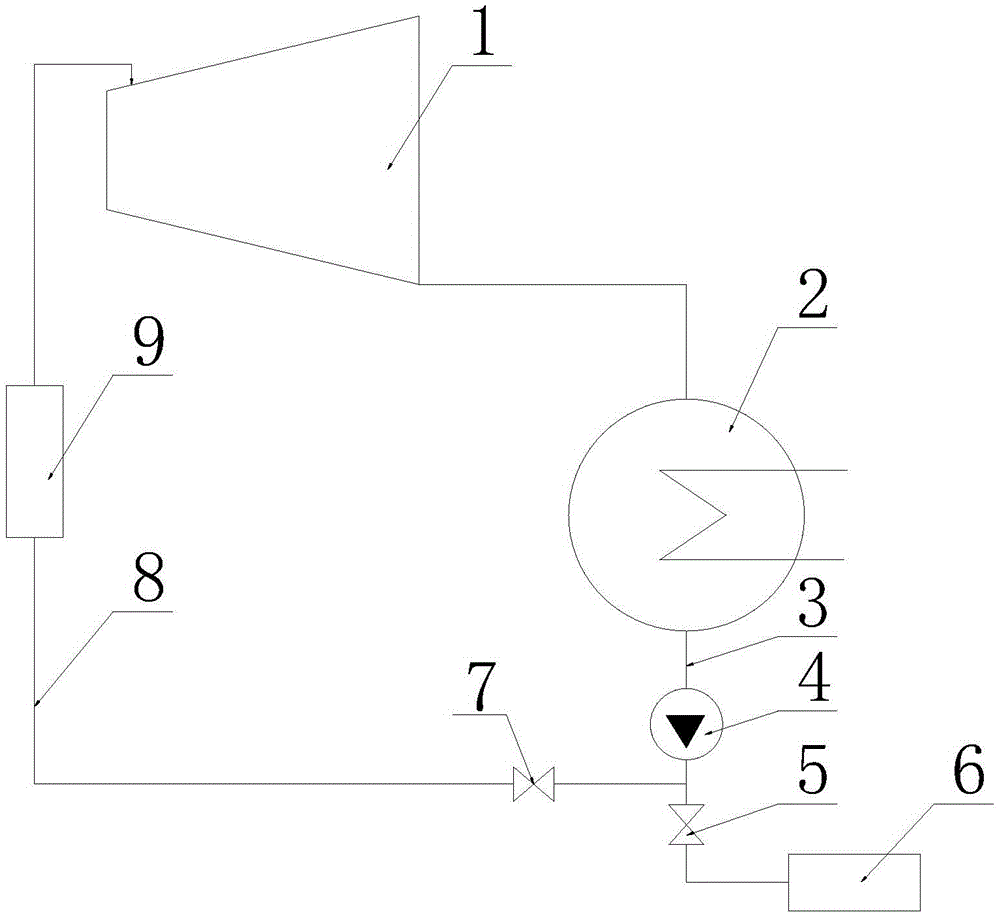

[0011] exist figure 1 Among them, the steam turbine blade fouling cleaning device includes steam turbine 1, which is connected to condenser 2, condensation pump 4, control valve A5 and condensate water system 6 in turn by pipeline 3, and is installed on the pipeline between control valve A and condensation pump The circulation pipe 8 is provided with a control valve B7 and a cleaning circulation system 9, one end of which is connected to a pipeline, and the other end extends into the regulating valve chamber of the steam turbine. Close the control valve A, fill the hot well of the condenser with cleaning liquid at about 80-90°C, open the control valve B, and start the condensation pump. The cleaning liquid enters the regulating valve chamber from the circulation pipe, and enters the steam turbine from the regulating valve hole. , Turn on the turning device for tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com