Tower drum of wind generating set and construction method of tower drum

A technology of wind power generating set and construction method, which is applied in the installation/supporting configuration of wind power engine, engine components, engine manufacturing, etc., which can solve problems such as poor economy, thick tower wall, and impossible design, so as to meet the needs, The effect of improving the support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

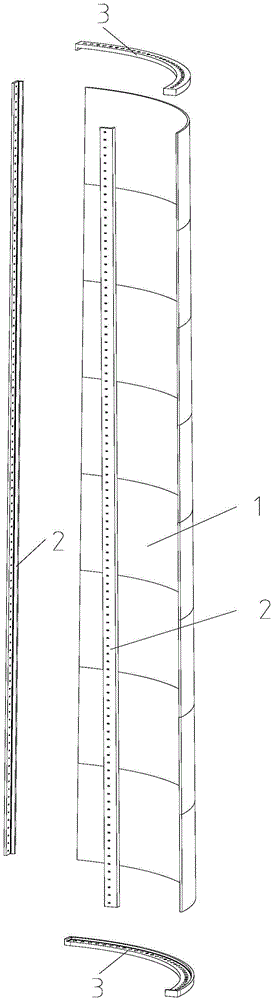

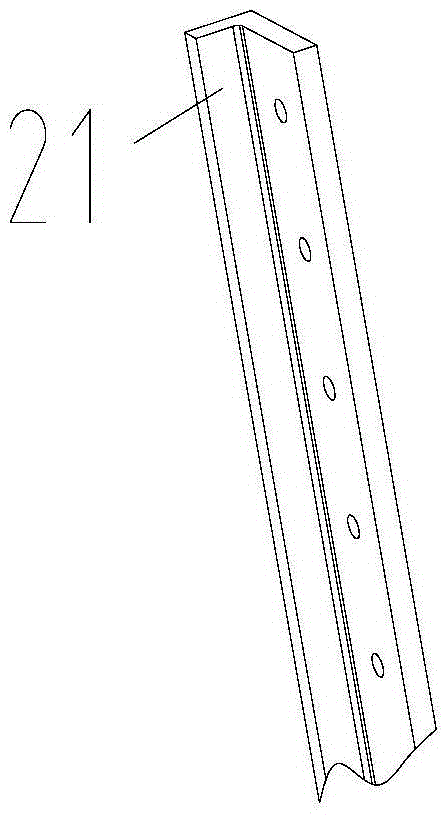

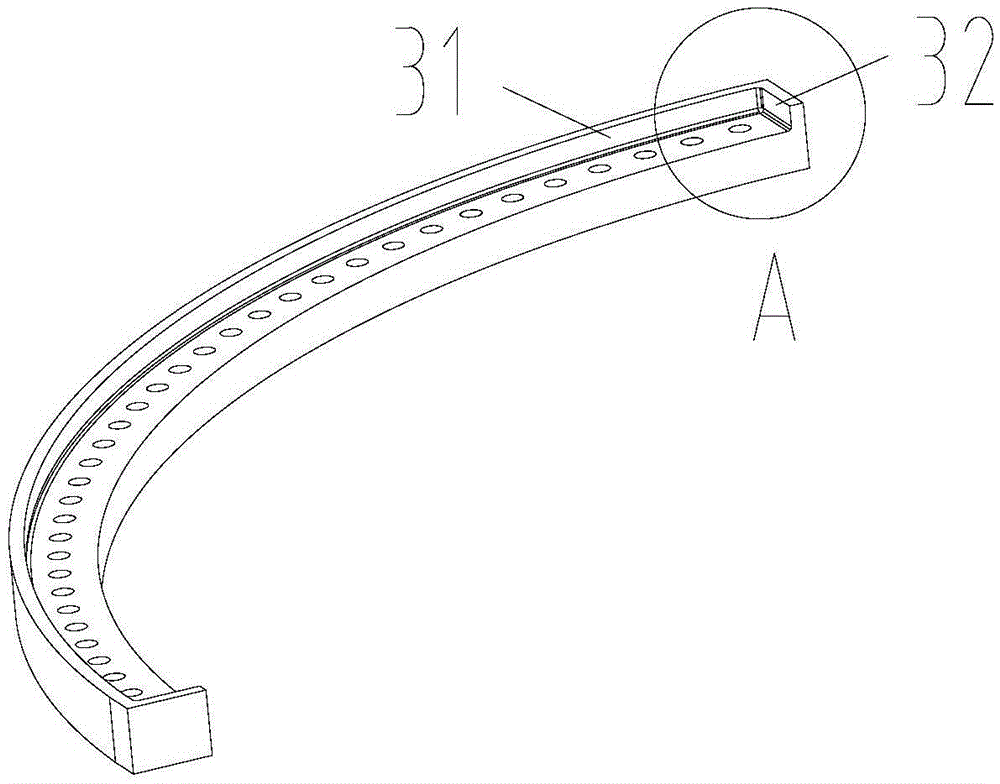

[0025] figure 1 It is a schematic structural diagram of an arc-shaped segment, a strip-shaped connecting portion, and an arc-shaped connecting portion according to an embodiment of the invention; figure 2 Yes figure 1 Enlarged view of the middle and long strip connection part; image 3 Yes figure 1 Enlarged view of the middle arc connection; Figure 4 Yes image 3 Partial enlarged view of region A in middle.

[0026] combined reference Figure 1 ~ Figure 4 , the embodiment of the present invention provides a tower of a wind power generating set, including a tower arc segment 1, a strip-shaped connecting part 2 fixed along the two sides of the tower arc segment 1, and a The bottom edge and the top edge of the cylindrical arc-shaped piece 1 are fixed to the arc-shaped connecting portion 3, and the elongated connecting portion 1 and the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com