Mechanical sealing structure for centrifugal pump

A centrifugal pump and mechanical seal technology, which is applied to the components, pumps, and pump elements of the pumping device for elastic fluids, and can solve the problems of damage to the outer coating, dimensional changes, wear, etc., to reduce the cost of spare parts and The effect of maintenance cost, elimination of hidden dangers of safety and environmental protection, and reduction of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

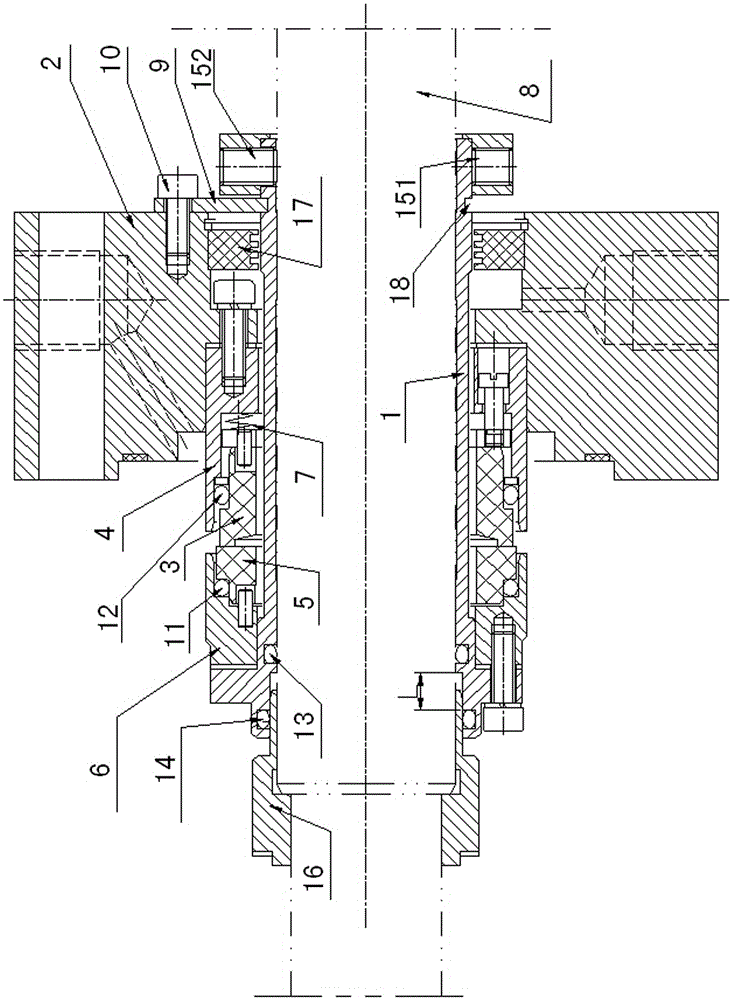

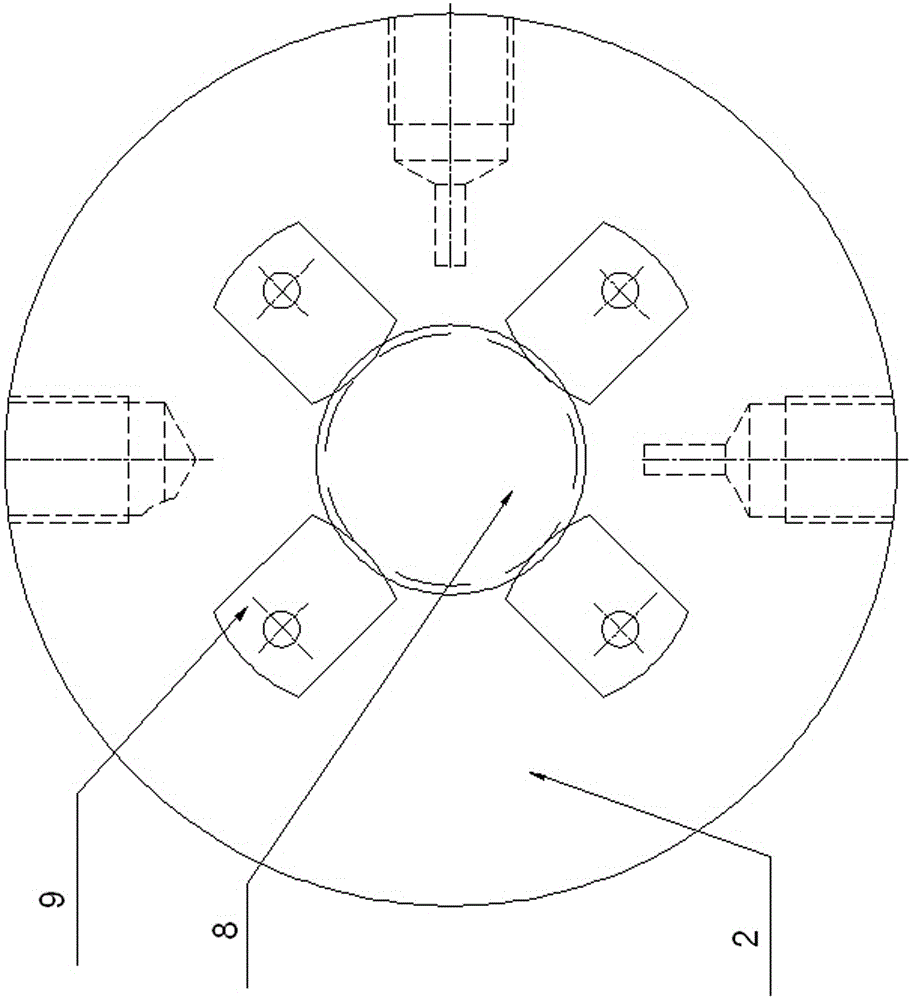

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1 and figure 2 As shown, the mechanical seal structure for a centrifugal pump of the present invention includes a static ring 3, a moving ring 5, a mechanical seal seat 2 and a shaft sleeve 1 fixedly sleeved on the pump shaft 8, and the static ring 3 is gapped between On the shaft sleeve 1, the moving ring 5 is sleeved on the shaft sleeve 1, and the shaft sleeve 1 is fixedly provided with a moving ring sealing seat 6 for limiting the moving ring 5 therein. The ring seal seat 6 is in transmission connection with the pump shaft 8, and the moving ring seal seat 6 can drive the moving ring 5 within the limit to rotate together with the pump shaft 8, and the gap between the machine seal seat 2 is set on the shaft On the cover 1, the machine seal seat 2 is fixed relative to the pump body.

[0025] A static ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com