Photoelectric aiming system look-down tracking test method and test device for implementing the method

A photoelectric aiming and testing device technology, applied in the direction of guidance, weapon accessories, offensive equipment, etc., can solve the problems of test blind spots, photoelectric aiming system unable to observe the collimator cursor, and unable to keep target tracking, etc., to achieve increased test , increase the range, and ensure a sufficient degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

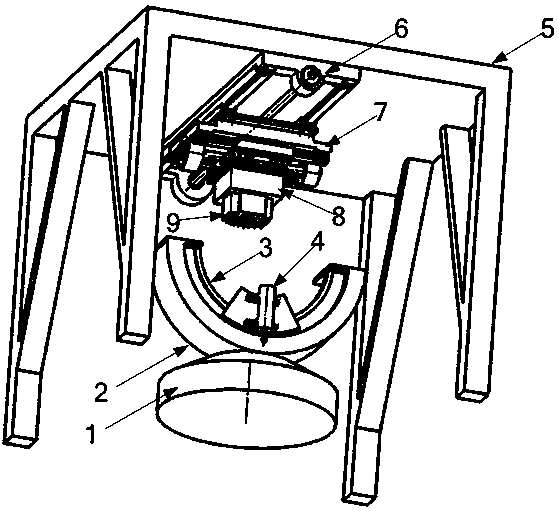

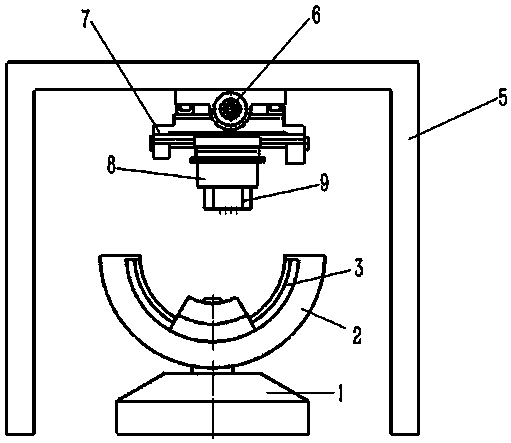

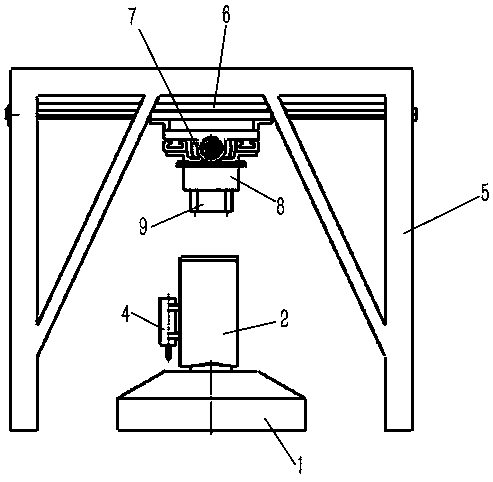

[0027] The embodiment of testing device among the present invention: as Figure 1 to Figure 4 As shown, the test device is a multi-frame decoupling downward-looking tracking test system in the technical field of airborne photoelectric sighting system control performance testing. It is mainly composed of a two-dimensional horizontal turntable and a hoisting base. A collimator is installed, and the hoisting base is used to install the photoelectric aiming system to be tested above the collimator.

[0028] The two-dimensional horizontal turntable includes a turntable base 1 and an azimuth frame 2 mounted on it that rotates around a vertically extending axis. Between the azimuth frame 2 and the collimator 4 is a device for driving the collimator 4 along the upper edge of the azimuth frame 2. A traverse mechanism that moves vertically in the direction of the rotation axis of the azimuth frame 2. The traverse mechanism includes a traverse guide rail 3 fixed on the azimuth frame 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com