A kind of measuring device and measuring method of solid content in solid-liquid system

A measurement method and solid-liquid system technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inappropriateness and inability to represent the overall characteristics of the system, and achieve convenient maintenance, simple and convenient maintenance, and good monochromaticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

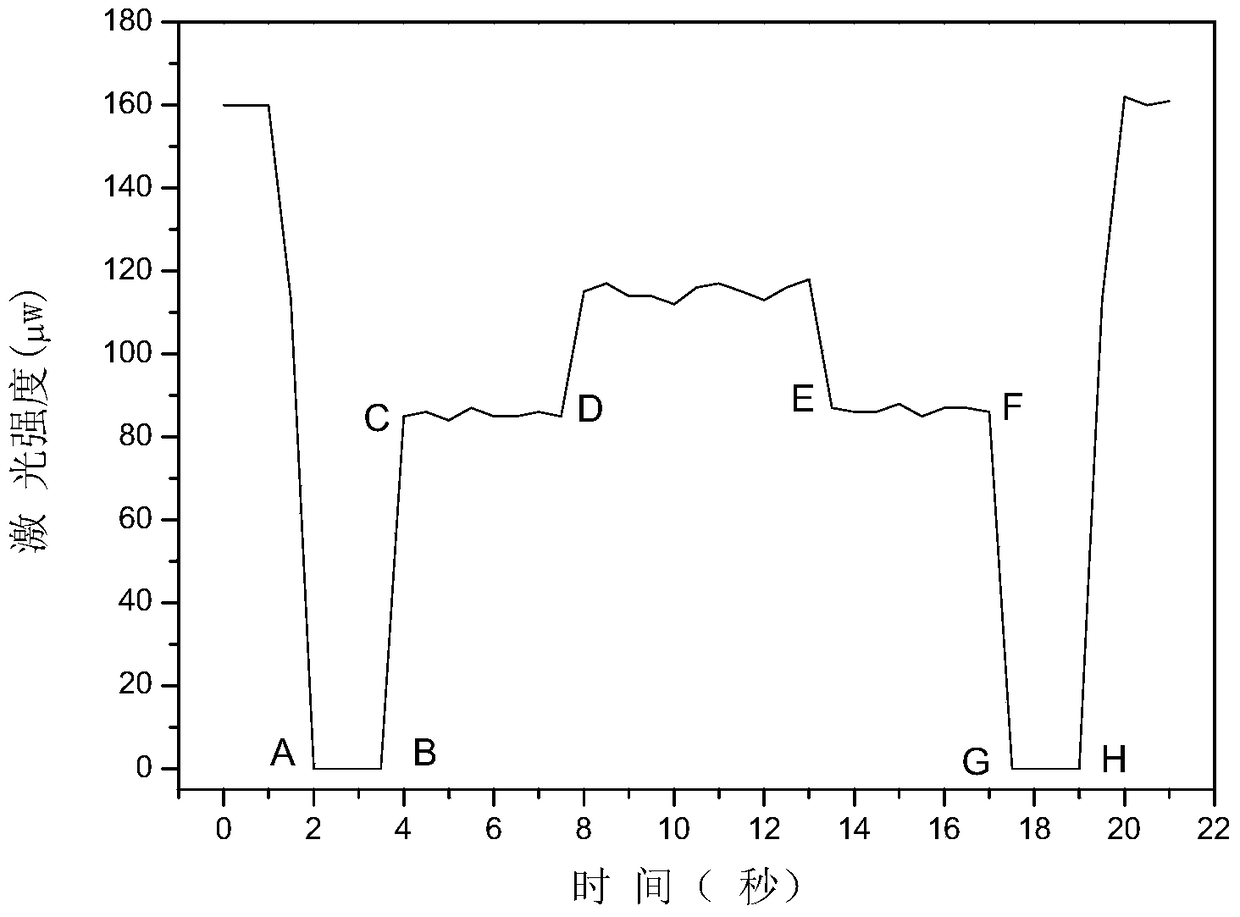

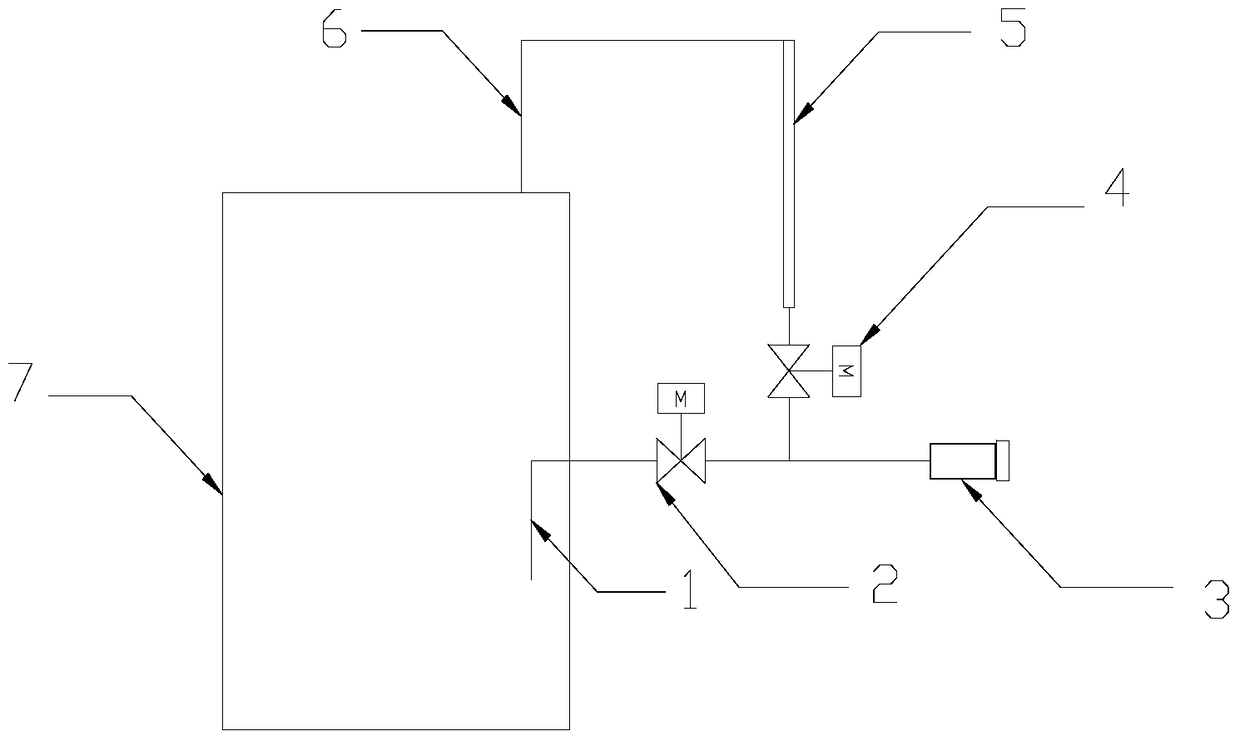

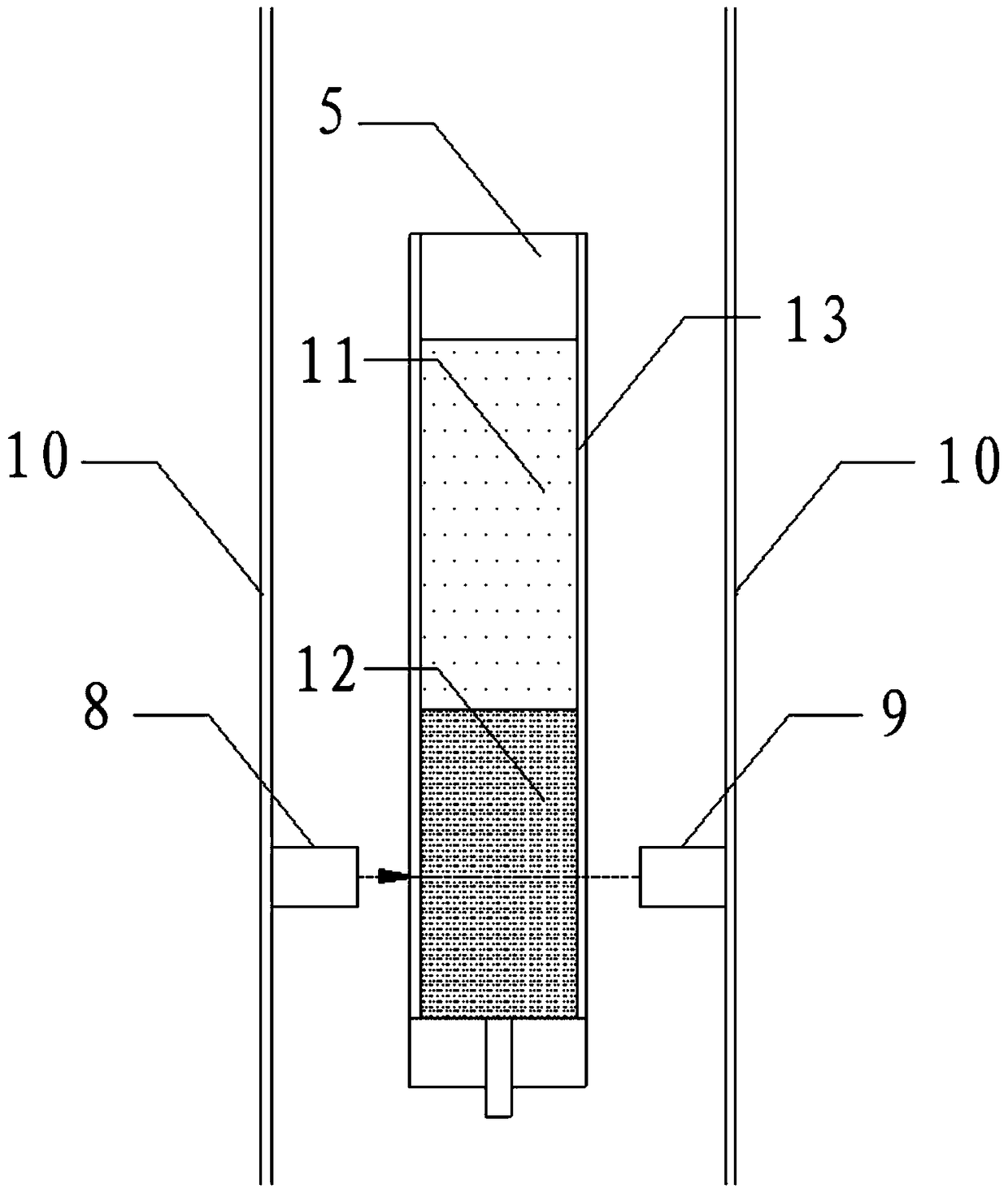

[0044] A device for measuring solid content in a solid-liquid system, including a collection unit, a measurement unit, and a recording unit. The collection unit includes a sampling tube and a metering pump. The metering pump is connected to a container to be measured through the sampling tube. The container to be measured is such as a chemical reaction container, Crystallization containers, experimental containers, etc.; the measurement unit includes a measuring tube, a signal generator, and a signal receiver. The intensity of the signal changes to display and measure the solid content. The measuring tube is connected to the metering pump through a pipeline, and the signal generator and signal receiver are located on both sides of the measuring tube; the signal receiver is connected to the recorder, and the recorder is used to display and store the received signal data.

[0045] The end of the sampling pipe connected to the metering pump is provided with a first valve, the end...

Embodiment 2

[0048] A measuring device for solid content in a solid-liquid system, the structure of which is as described in Example 1, the difference is that, further, a scale is provided on the wall of the measuring tube. Convenient and intuitive display of solid-liquid content.

Embodiment 3

[0050] A device for measuring solid content in a solid-liquid system, the structure of which is as described in Example 1, the difference is that further, the measuring tube is connected to the container to be measured through a connecting tube. It is used to maintain the technical indicators such as pressure and temperature in the measuring tube consistent with the indicators of the container to be measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com