A wire break detection system and detection method for a twisting machine

A technology of wire breakage detection and stranding machine, applied in the direction of linear/angular velocity measurement, devices using electric/magnetic methods, measuring devices, etc., can solve the problems of low detection accuracy and blind spots in detection, and achieve accurate detection speed, Detect targeted, error-optimized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

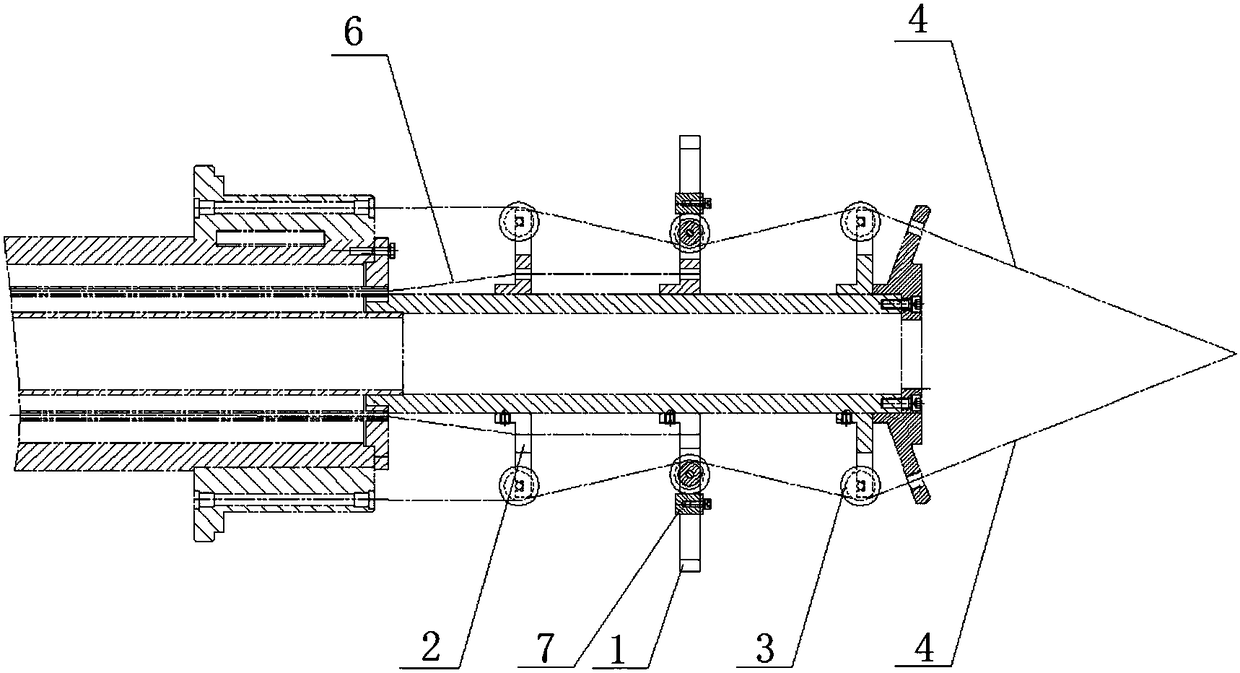

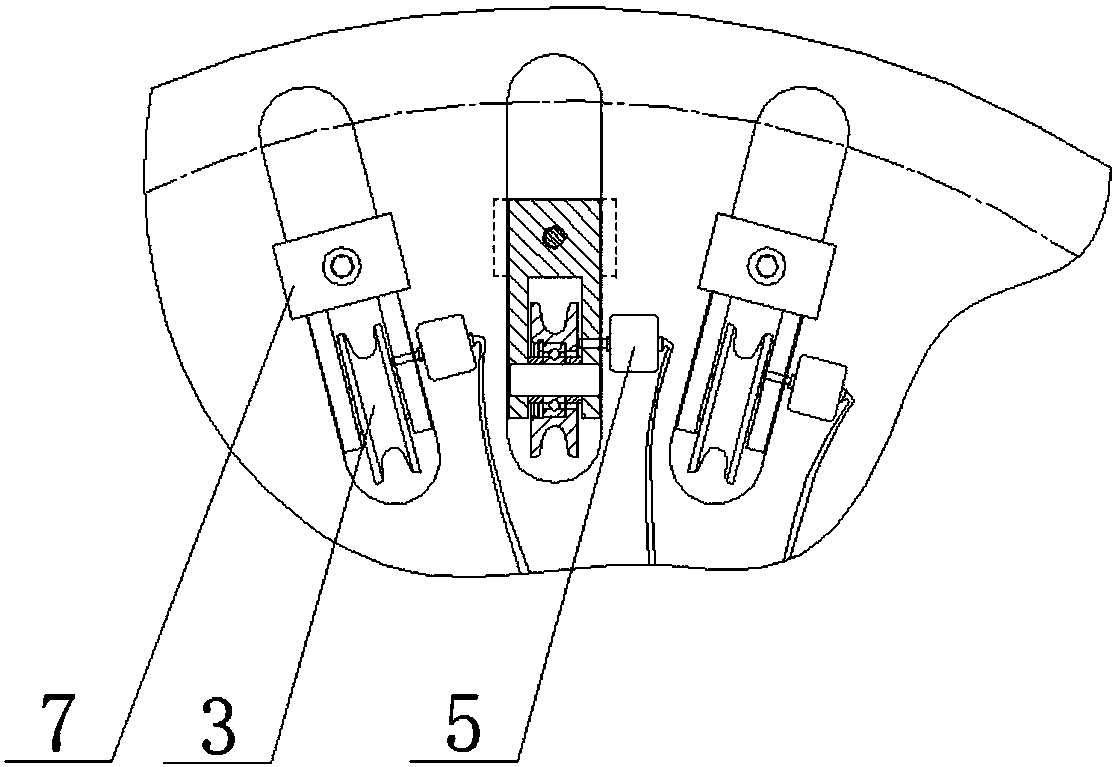

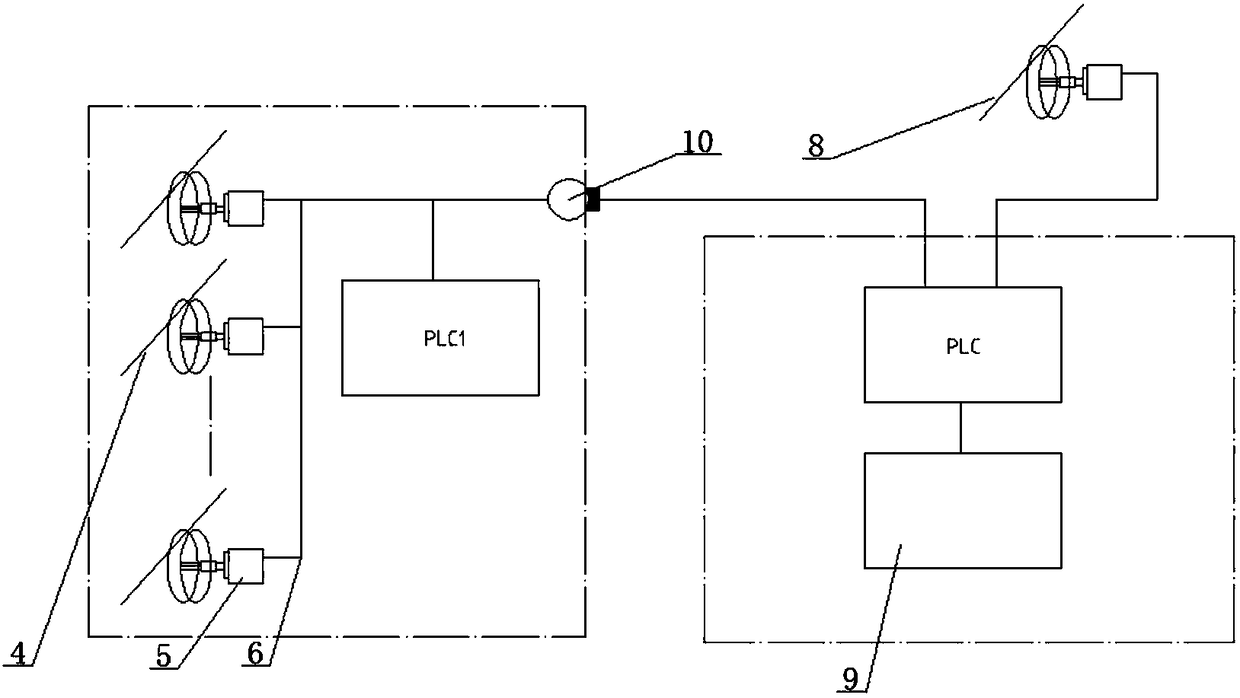

[0046] like figure 1 , 2 As shown, a wire break detection system of a stranding machine of the present invention includes a stranding machine and a stranding machine control system. The stranding machine twists a number of wire cores 4 with the cable core 4 through the main shaft where it is located, and the main shaft is evenly distributed There is a wire stranding device with a wire core, and the vertical surface of the main shaft of the stranding machine body is respectively provided with a circle of pre-twist bracket 1 and two circles of bracket 2, and the pre-twist bracket 1 and bracket 2 are evenly distributed on the plane where they are located. The pre-twisted bracket 1 is arranged in the center of the two side brackets 2, and the heights of the two side brackets are the same. The top of each bracket 2 is provided with a guide wheel 3, and each pre-twisted bracket 1 is provided with a guide wheel 3. The height of the guide wheel 3 is lower than the height of the guide...

Embodiment 2

[0065] A wire breakage detection system of a stranding machine of the present invention includes a stranding machine and a stranding machine control system. The stranding machine twists a number of wires with the cable core 4 through the main shaft where it is located, and the wires are evenly distributed around the main shaft. Core stranding equipment, the vertical surface of the main shaft of the stranding machine body is respectively provided with a circle of pre-twisted bracket 1 and two circles of bracket 2, and the pre-twisted bracket 1 and bracket 2 are evenly distributed on the plane where the pre-twisted bracket 1 is located. The bracket 1 is set in the center of the brackets 2 on both sides, the heights of the brackets 2 on both sides are the same, the top of each bracket 2 is provided with a guide wheel 3, and each pre-twist bracket 1 is provided with a guide wheel 3, and the guide wheel 3 on the pre-twist bracket 1 The height is lower than the height of the guide wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com