Power transformer loss live-line measurement and hot spot temperature prediction system and method

A technology of power transformer and prediction system, applied in the field of power system, can solve the problems of not fully utilizing the load capacity of the transformer, reducing economic benefits, accelerating insulation aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

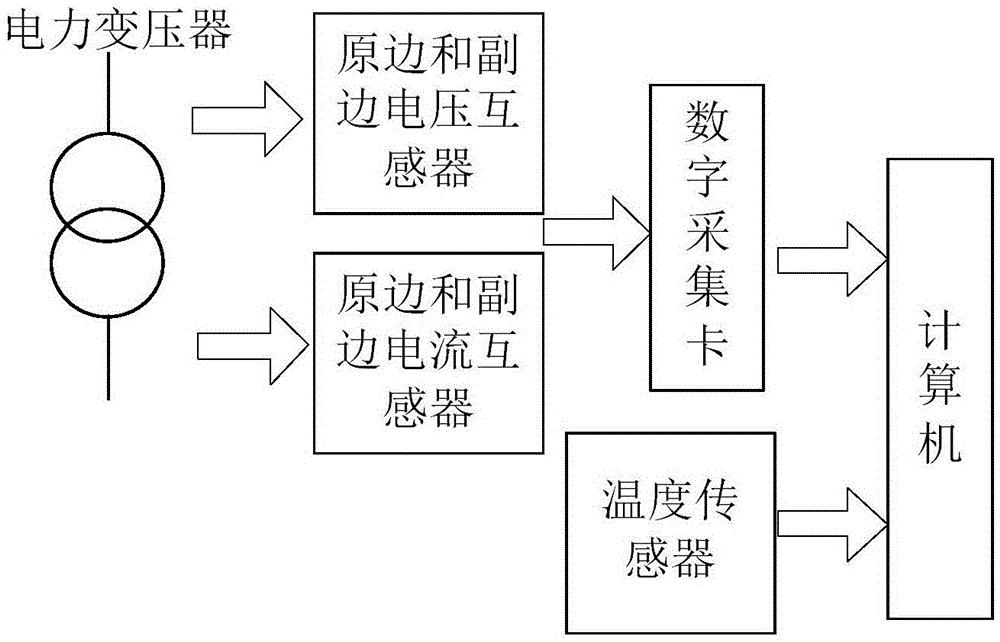

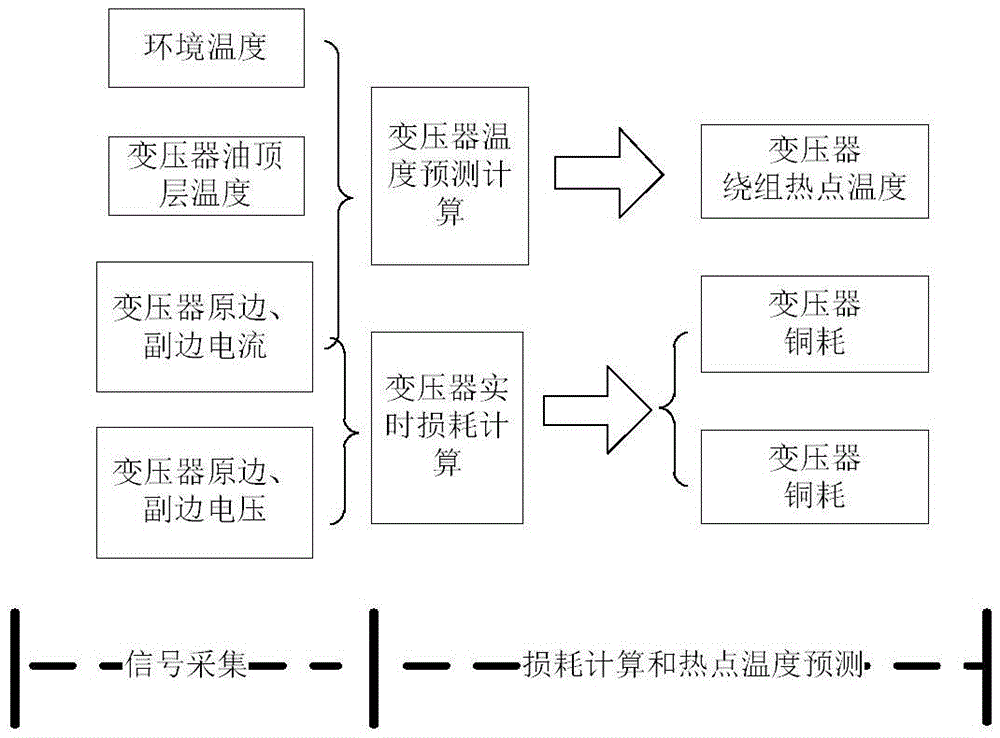

[0036] see figure 1 As shown, a power transformer loss live measurement and hot spot temperature prediction system of the present invention includes a computer, a digital acquisition card, a temperature sensor, a primary voltage transformer, a secondary voltage transformer, a primary current transformer, and a secondary current transformer. device.

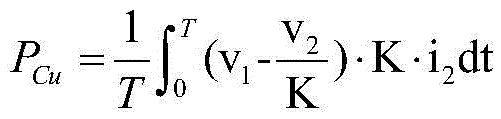

[0037] The output ends of the primary side voltage transformer, the secondary side voltage transformer, the primary side current transformer and the secondary side current transformer are connected to the input end of the digital acquisition card, and the output end of the digital acquisition card and the output end of the temperature sensor are connected to the computer. The primary side voltage transformer and the secondary side voltage transformer are respectively set on the primary side and the secondary side of the power transformer, which are used to collect the primary side and secondary side voltage of the power transforme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com