Thermosyphon type defrosting dual-channel oil and gas recovery condensing unit

A technology of thermosyphon and condensing units, which is applied in the direction of refrigerators, refrigeration components, compressors, etc., can solve the problems of unsafe equipment and complex pipelines of the system, and achieve simple structure, improved stability, and high coldness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

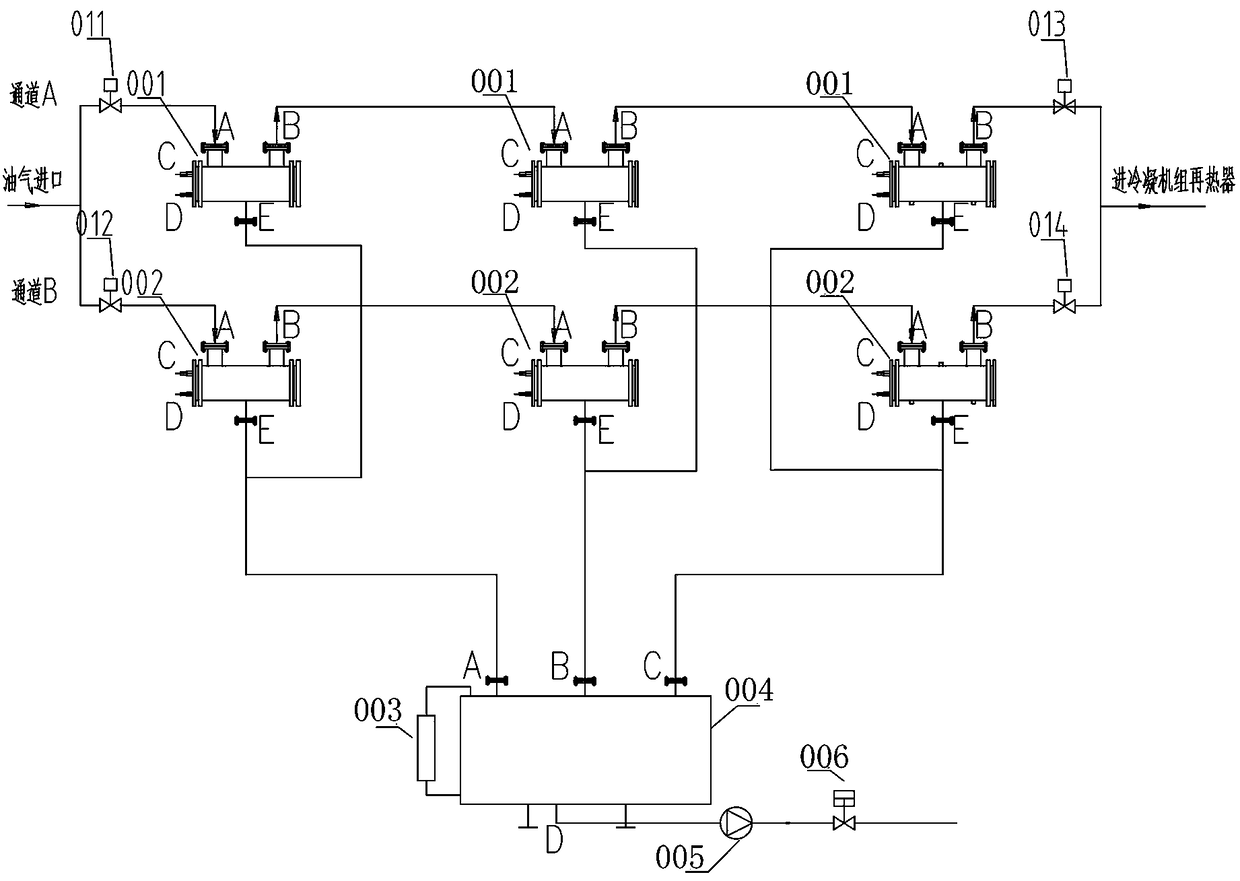

[0017] Such as figure 1 As shown, the dual-channel oil-gas switching and oil collection system includes a switching electric valve, a first evaporator 001, a second evaporator 002, an oil delivery pump 009, an electric valve 010, an oil storage tank 008 and a liquid level gauge 007. Among them, the oil and gas condensation is divided into two channels, A and B. Wherein, the switching electric valves on channel A are the first main valve 011 and the third main valve 013; the switching electric valves on channel B are the second main valve 012 and the fourth main valve 014. In channel A, the oil and gas pass through the first main valve 011, pass through three first evaporators 001 and the third main valve 013 in sequence, and then enter the oil and gas reheater of the condensing unit. In channel B, the oil and gas pass through the second main valve 012, pass through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com