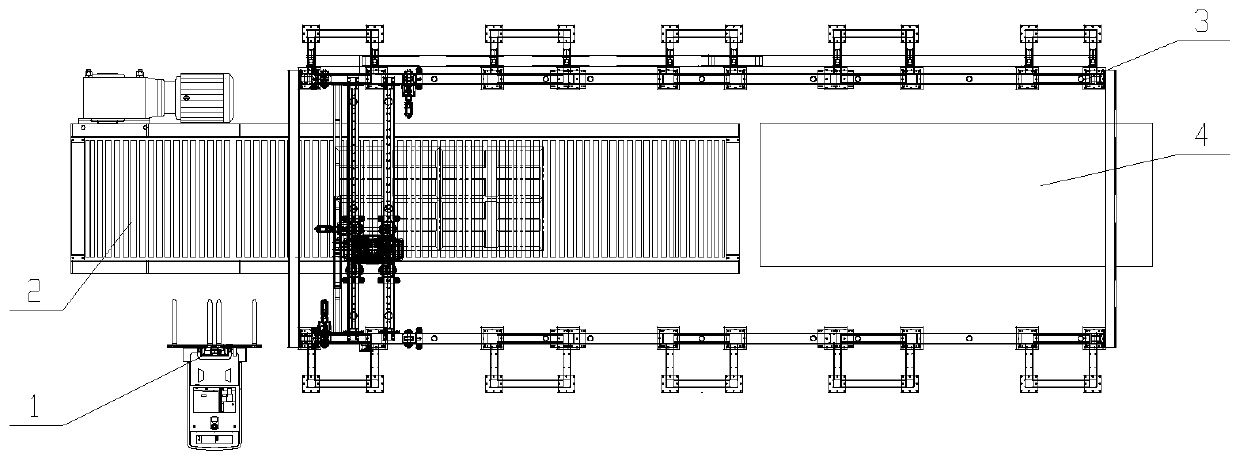

Loading system and loading method

A technology for forklifts and car bodies, applied in hoisting devices, load pulleys, loading/unloading, etc., can solve the problems of large site area, unreasonable layout of production lines and warehouses, safety risks, etc., and achieve reasonable operation and good economic benefits. and social benefits, the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

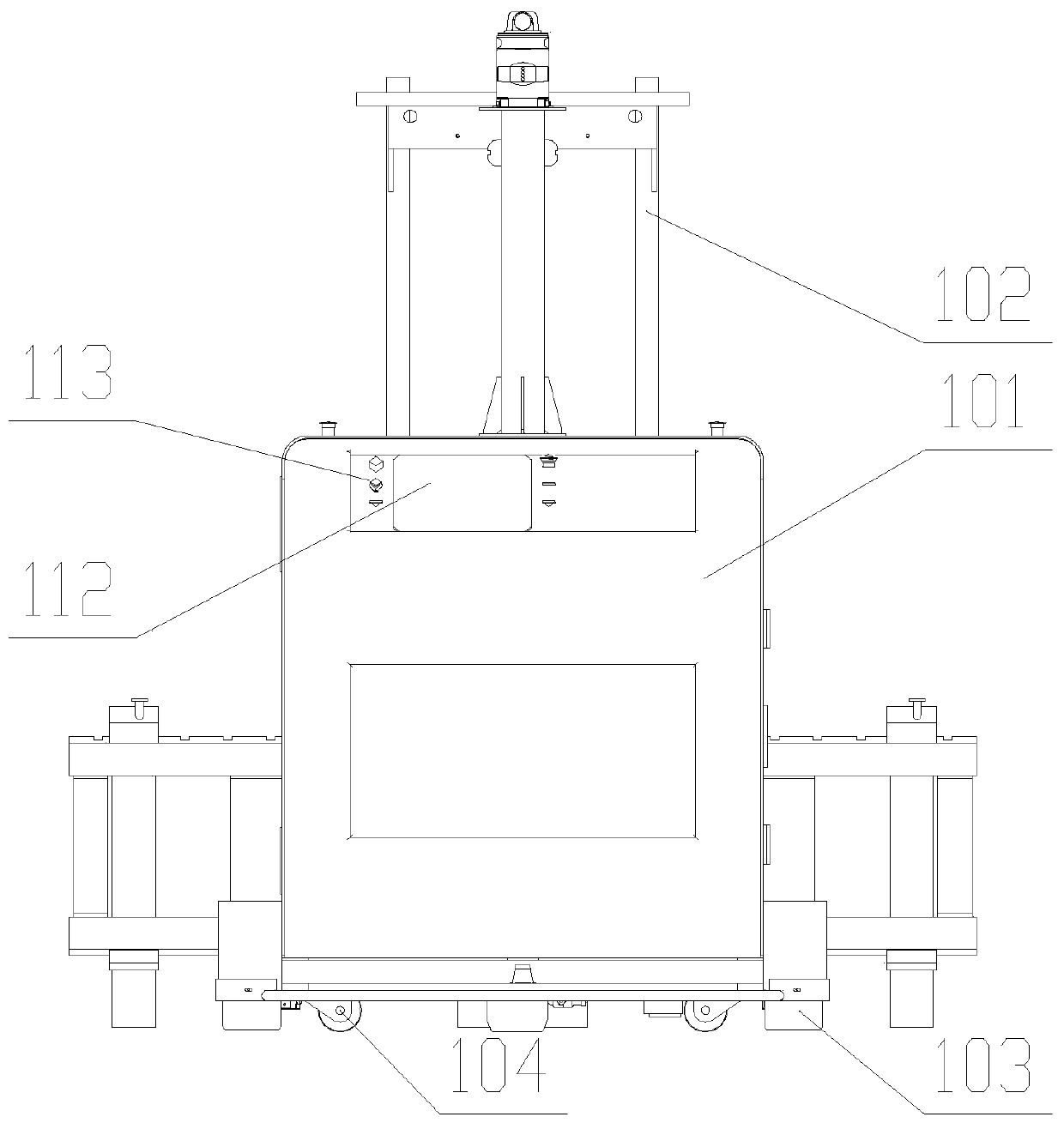

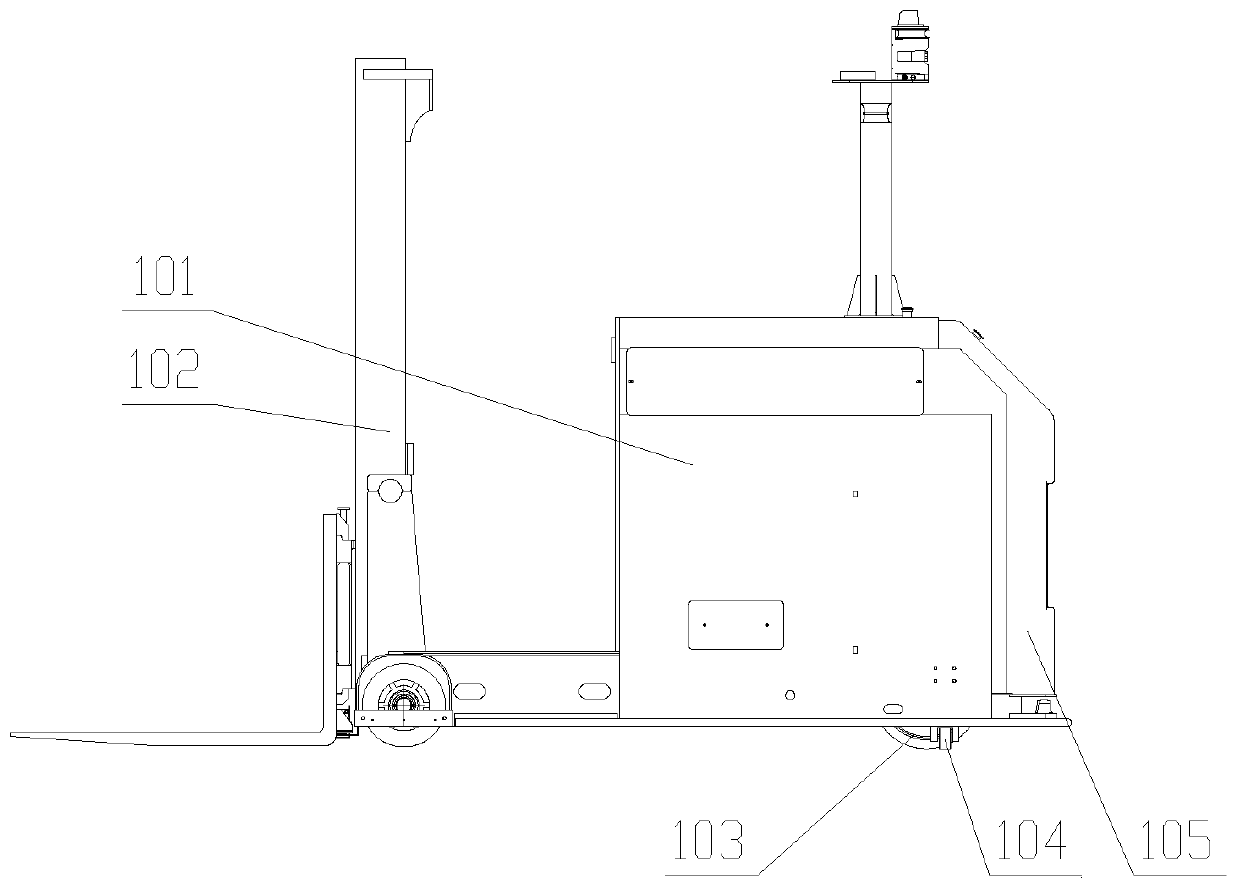

[0054] Embodiment 1. One side of the operation panel 113 is provided with a buzzer alarm, a system interface, and a battery switch in sequence from top to bottom; the other side of the operation panel 113 is provided with an emergency stop switch, a stop button, a start button, and button.

Embodiment 2

[0055] Embodiment two, such as Figure 10 As shown, the traveling cart assembly 302 is a double-girder traveling carriage, which can move along the Y-axis, and the speed of the Y-axis is 1m / s; the power of the Y-axis motor is 4.87KW 3000RPM; The reduction ratio of the shaft reducer is 1:30;

[0056] The walking trolley 303 can move along the X-axis, and the X-axis speed is 1m / s; the power of the X-axis motor is 3.12KW 3000RPM (2 sets); the reduction ratio of the X-axis reducer is 1:30 (2 sets);

[0057] The lifting mechanism assembly 304 is driven by a motor, and the lifting function of the lifting shaft is realized through the rack and pinion. The lifting shaft of the lifting mechanism assembly 304 can move along the Z axis, and the Z axis speed is 0.2m / s; the Z axis motor power is 5KW 2000RPM; the reduction ratio of the Z-axis reducer is 1:70; the lifting range is 1500mm-2405mm;

[0058] The rotary mechanism assembly 305 is driven by a motor, and the rotation of the mechan...

Embodiment 3

[0060] Embodiment 3. The laser forklift 1 includes a forklift and a control system. The control system includes a forklift AGV dispatching system, a forklift AGV monitoring system, and a forklift AGV charging system. The company's high-precision controller CVC600 realizes unmanned automatic operation;

[0061] The laser forklift 1 transports the designated goods one by one to the conveying line next to the truss robot 3. The operator of the conveying line controls the flat conveyor to push the goods under the mechanical gripper; According to the model and loading capacity of the current vehicle, the cargo is hoisted by the mechanical gripper of the truss robot 3, the mechanical gripper is lifted, and the direction of the cargo is turned 90 degrees to walk in the direction of the 4th compartment of the freight truck, and then enter according to the front queue. After the hoisting personnel store the goods in the cargo truck compartment, they open and lift the mechanical gripper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com