Three-dimensional flow thermal coupling modeling method for cement grate cooler

A fluid-thermal coupling and modeling method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the grate cooler system with complex process, many related factors, and inaccurate reaction grate cooler working process And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Taking the grate cooler on the general dry process cement production line as an example below, the present invention will be further described in conjunction with the accompanying drawings

[0079] A kind of three-dimensional fluid heat coupling modeling method of the present invention for cement grate cooler, its content comprises the following steps:

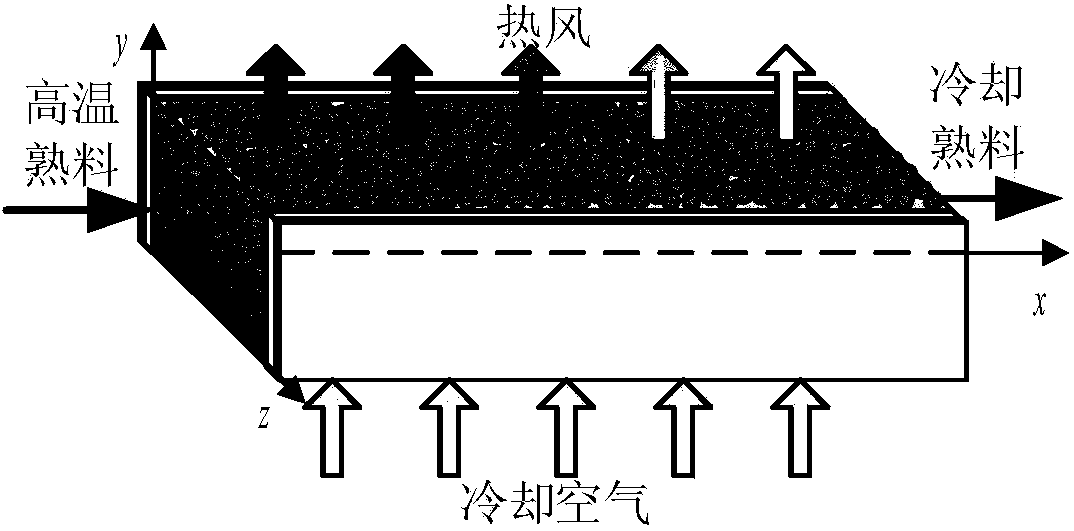

[0080] Step 1, the clinker cooling process in the grate cooler is abstracted as figure 1 Fluid-heat coupling physical model of a three-dimensional porous medium composed of accumulated particles; high-temperature clinker particles enter the grate bed from the left side of the model, move slowly to the right under the push of the grate plate, during which they are continuously cooled by the air blown in from the lower part, and finally flow out At the right end of the grate bed, the temperature of the clinker gradually decreases under the action of the cooling air; in the figure, x is the direction of the bed length, y i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com