Method for lowering influence of reverse current on battery voltage-resistant insulation test

A technology of withstand voltage insulation and reverse current, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc. It can solve problems affecting the judgment of the output voltage of the tester, battery discharge, and the judgment results of the withstand voltage insulation test, etc., to increase the number , reduce the defective rate, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

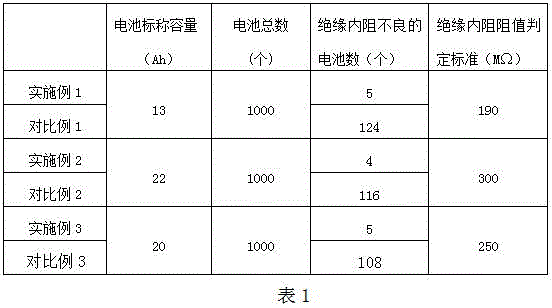

Embodiment 1

[0013] Embodiment 1: A method for reducing the impact of backflow current on the battery withstand voltage insulation test, comprising the following steps:

[0014] (1) Select 1,000 batteries to be tested with a nominal capacity of 13Ah, and form them by laser welding;

[0015] (2) Under the test voltage of 75V, carry out the withstand voltage insulation test, and the test time is 3s;

[0016] (3) Use 190MΩ as the qualified standard for the insulation internal resistance value to determine the withstand voltage insulation test results.

Embodiment 2

[0017] Embodiment 2: A method for reducing the influence of backflow current on battery withstand voltage insulation test, comprising the following steps:

[0018] (1) Select 1,000 batteries to be tested with a nominal capacity of 22Ah, and form them by laser welding;

[0019] (2) Under the test voltage of 250V, carry out the withstand voltage insulation test, and the test time is 10s;

[0020] (3) Use 300MΩ as the qualified standard for the insulation internal resistance value to determine the withstand voltage insulation test results.

Embodiment 3

[0021] Embodiment 3: A method for reducing the influence of reverse flow current on battery withstand voltage insulation test, comprising the following steps:

[0022] (1) Select 1,000 batteries to be tested with a nominal capacity of 20Ah, and form them by laser welding;

[0023] (2) Under the test voltage of 300V, carry out the withstand voltage insulation test, and the test time is 6s;

[0024] (3) Use 250MΩ as the qualified standard for the insulation internal resistance value to determine the withstand voltage insulation test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com