Efficient heat dissipation case

A kind of chassis, high-efficiency technology, applied in the direction of screening casing, chemical industry, instruments, etc., can solve the problems of hardware damage, lack of heat dissipation effect, etc., and achieve excellent heat dissipation effect and good electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

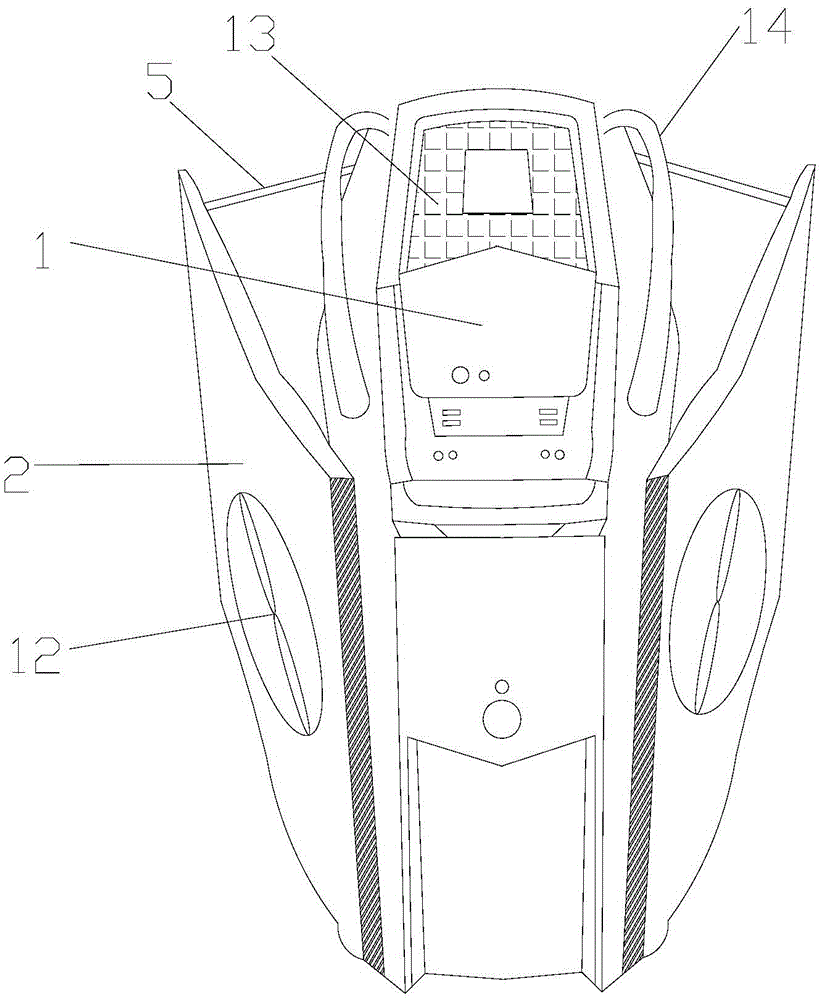

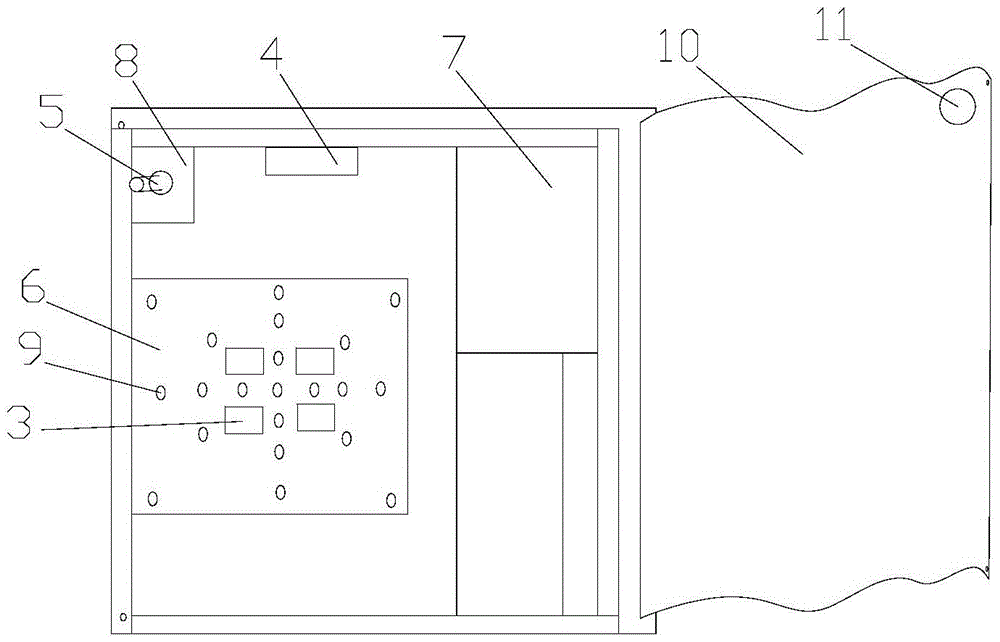

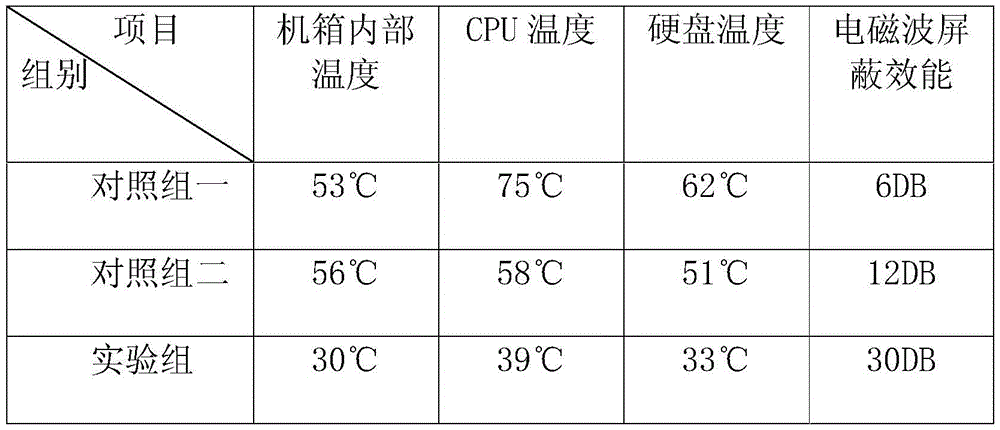

[0027] Such as Figure 1-2 As shown, a high-efficiency heat dissipation chassis includes a box body 1, a side cover 2, a temperature sensor 3, an electronic switch 4 and an electro-hydraulic rod 5, and the box body 1 is provided with a heat conducting plate 6, a hard disk bracket 7 and a connecting block 8. Air holes 9 and screw holes (not shown) are provided on the heat conduction plate 6, which can facilitate the user to install the main board on the heat conduction plate 6. Both sides of the box body 1 are provided with anti-radiation fabrics 10, so The radiation-proof fabric 10 is connected to the box body 1 by bolts (not shown), the radiation-proof fabric 10 is provided with through holes 11, the side cover 2 is hingedly connected with the box body 1, and the side cover 2 is provided with There is a fan 12, the temperature sensor 3 is embedded in the heat conduction plate 6, the electronic switch 4 is installed on the inner surface of the box body 1, the electro-hydraulic...

Embodiment 2

[0044] Such as Figure 1-2As shown, a high-efficiency heat dissipation chassis includes a box body 1, a side cover 2, a temperature sensor 3, an electronic switch 4 and an electro-hydraulic rod 5, and the box body 1 is provided with a heat conducting plate 6, a hard disk bracket 7 and a connecting block 8. Air holes 9 and screw holes (not shown) are provided on the heat conduction plate 6, which can facilitate the user to install the main board on the heat conduction plate 6. Both sides of the box body 1 are provided with anti-radiation fabrics 10, so The radiation-proof fabric 10 is connected to the box body 1 by bolts (not shown), the radiation-proof fabric 10 is provided with through holes 11, the side cover 2 is hingedly connected with the box body 1, and the side cover 2 is provided with There is a fan 12, the temperature sensor 3 is embedded in the heat conduction plate 6, the electronic switch 4 is installed on the inner surface of the box body 1, the electro-hydraulic ...

Embodiment 3

[0061] Such as Figure 1-2 As shown, a high-efficiency heat dissipation chassis includes a box body 1, a side cover 2, a temperature sensor 3, an electronic switch 4 and an electro-hydraulic rod 5, and the box body 1 is provided with a heat conducting plate 6, a hard disk bracket 7 and a connecting block 8. Air holes 9 and screw holes (not shown) are provided on the heat conduction plate 6, which can facilitate the user to install the main board on the heat conduction plate 6. Both sides of the box body 1 are provided with anti-radiation fabrics 10, so The radiation-proof fabric 10 is connected to the box body 1 by bolts (not shown), the radiation-proof fabric 10 is provided with through holes 11, the side cover 2 is hingedly connected with the box body 1, and the side cover 2 is provided with There is a fan 12, the temperature sensor 3 is embedded in the heat conduction plate 6, the electronic switch 4 is installed on the inner surface of the box body 1, the electro-hydraulic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap