Prediction method for temperature field in electromagnetic induction heating process of steel plate

A technology of electromagnetic induction heating and induction heating, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., and can solve the problems of increased cost, low precision, and labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

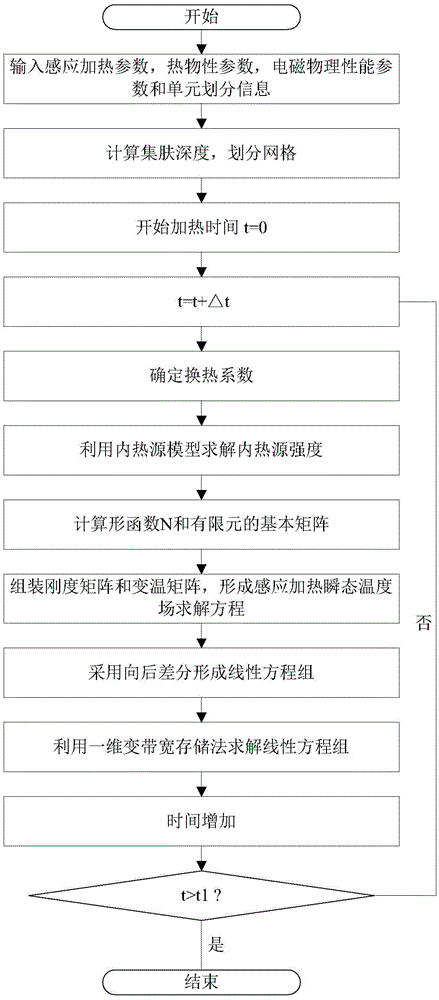

[0067] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0068] Realize the technical solution of the object of the present invention as follows:

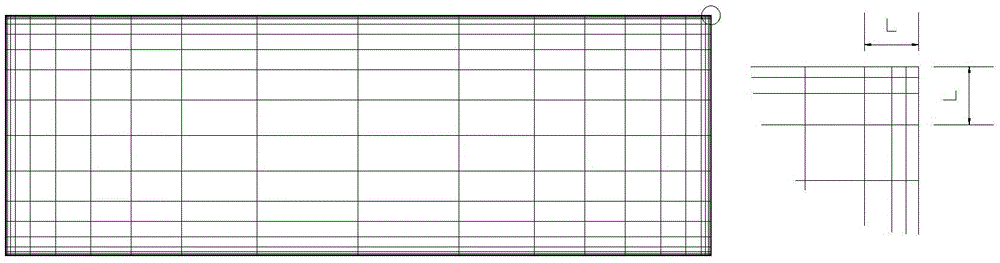

[0069] 1. Collect steel plate induction heating process data, including: induction heating parameters, material thermal and physical properties parameters, material electromagnetic performance parameters, and unit division information.

[0070] Induction heating parameters: working frequency, current density, gap (distance between coil and steel plate surface), heating time, workpiece width, workpiece thickness, initial temperature of workpiece, ambient temperature.

[0071]Material thermophysical parameters: thermal conductivity, blackness, specific heat, density.

[0072] Materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com