Safety driving motor

A technology of safe drive and casing, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of lack of a good protection measure, the rotation is blocked, the motor coil is burned, etc., to achieve the overload protection function, The effect of stable working condition and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

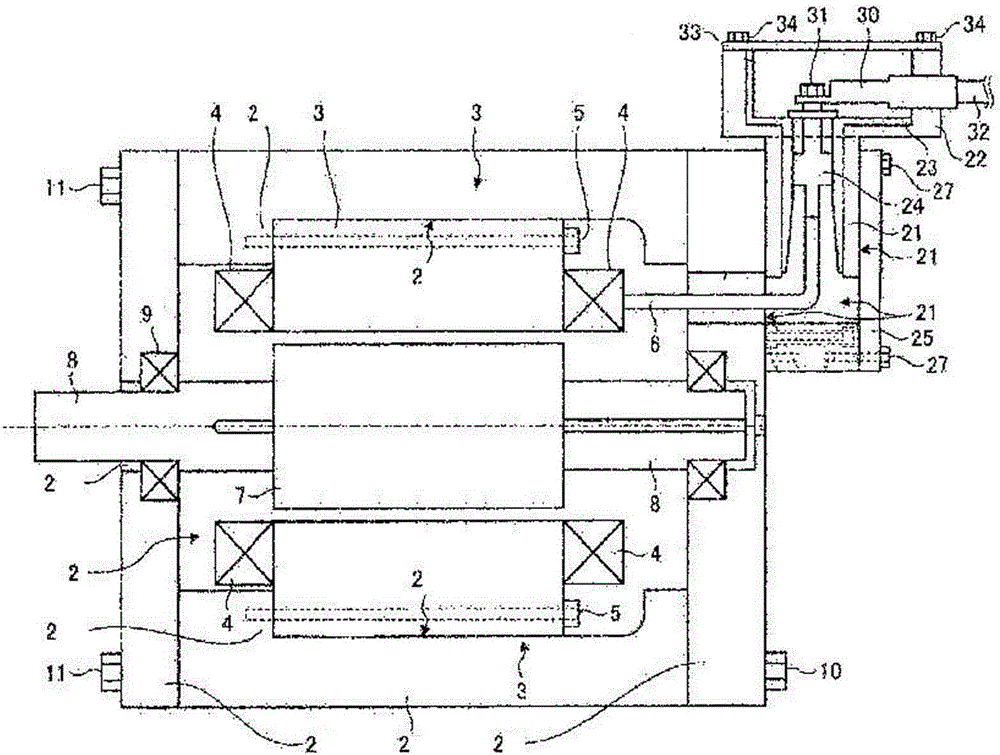

[0015] A safe driving motor of the present invention comprises a casing 2, a coil 3, a mounting seat 23, a connecting screw 5, a temperature sensor 6, a rotor 8, a first outer nut 10, a second outer nut 11, a connecting frame 21, and a mounting frame 22. Mounting seat 23, data cable rack 24, connection plate 25, connection nut 27, data output terminal 30, data nut 31, data connector 32, cover plate 33, upper nut 34, characterized in that: the casing 2 A coil 3 is provided, and a rotor 8 is provided inside the coil 3 . A temperature sensor 6 is provided on the coil 3 inside the housing 2 .

[0016] As a preferred solution of the present invention, the data line rack 24 is arranged in the connecting frame 21 outside the casing 2 .

[0017] Further, the data output terminal 30 is fixed on the upper end of the connecting frame 21 through the cover plate 33 .

[0018] A solar support structure of the present invention includes a casing 2, a coil 3, a mounting seat 23, a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com