Liquid crystal display element, liquid crystal alignment treatment agent, and liquid crystal alignment film

A technology of liquid crystal alignment film and liquid crystal alignment, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of large power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0269] The following examples are given to illustrate the present invention in more detail, but they are not limitedly interpreted. In addition, the abbreviations of the compounds used in the synthesis example, the Example, and the comparative example are as follows.

[0270]

[0271] (liquid crystal) L1: MLC-6608 (manufactured by MERCK CORPORATION)

[0272] (polymerizable compound) R1: a compound represented by the following formula [R1]

[0273] (Photoinitiator) P1: a compound represented by the following formula [P1]

[0274]

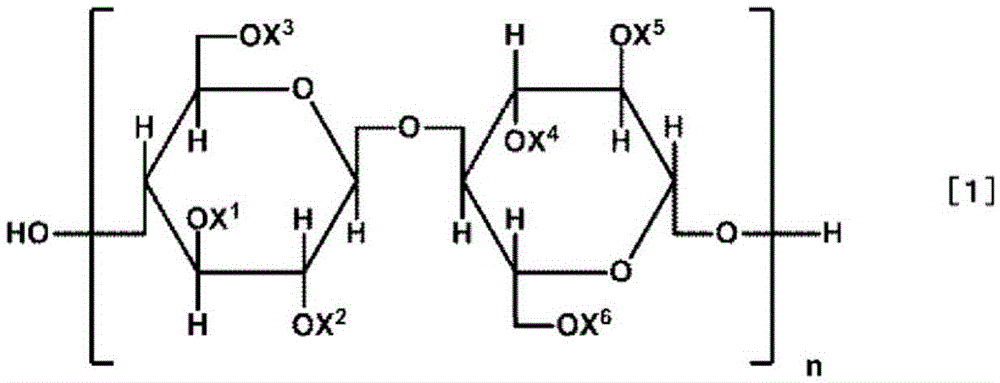

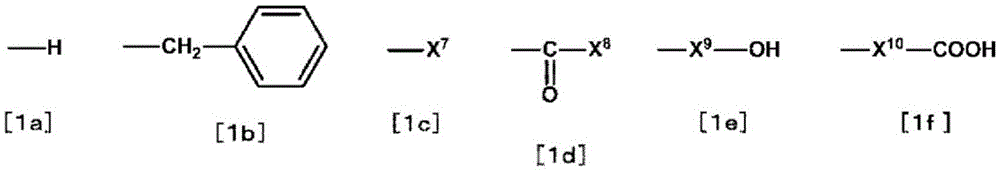

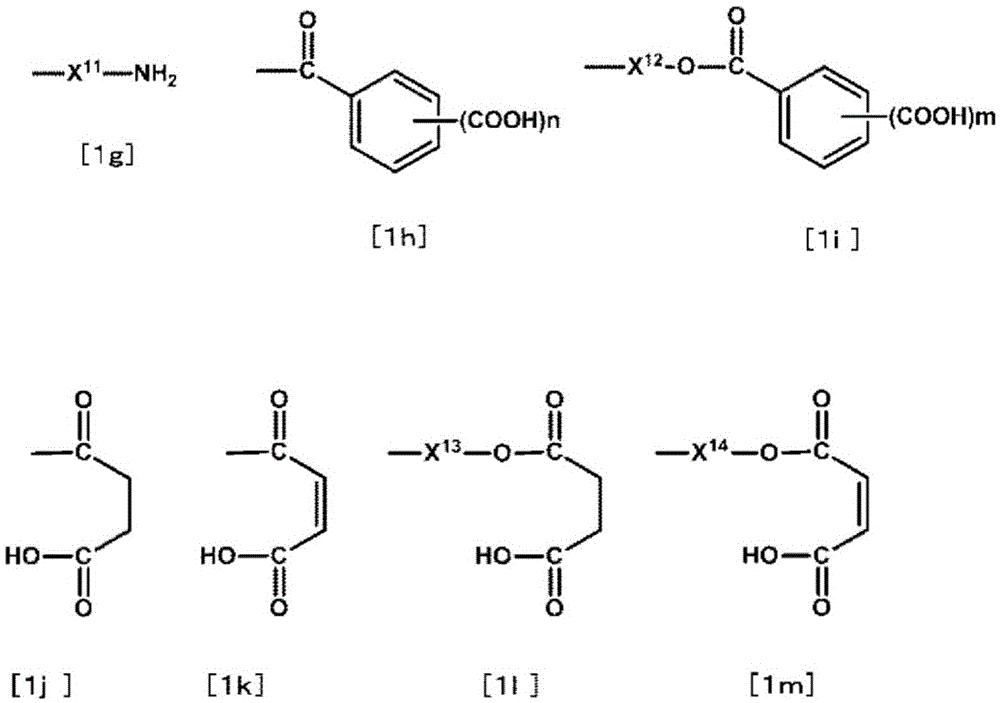

[0275] (specific cellulosic polymer)

[0276] CE-1: Hydroxyethylcellulose (manufactured by Wako Pure Chemical Industries, Ltd.)

[0277] CE-2: Hydroxypropylmethylcellulose phthalate (manufactured by ACROS)

[0278] (alkoxysilane monomer)

[0279] E1: Alkoxysilane represented by the following formula [E1]

[0280] E2: Octadecyltriethoxysilane

[0281] E3: 3-methacryloxypropyltrimethoxysilane

[0282] E4: 3-Ureapropyltriethoxysilane

[02...

Synthetic example 1

[0305] In a 200ml four-necked reaction flask equipped with a thermometer and a reflux tube, ECS (28.3g), E1 (4.10g), E3 (7.45g) and E5 (32.5g) were mixed to prepare a solution of the alkoxysilane monomer. A solution prepared by mixing ECS (14.2 g), water (10.8 g), and oxalic acid (0.70 g) as a catalyst was added dropwise to this solution over 30 minutes at 25° C., followed by stirring at 25° C. for 30 minutes. Then, after heating using an oil bath and refluxing for 30 minutes, the mixed solution of the methanol solution (1.20g) and ECS (0.90g) which content of E4 prepared beforehand was 92 mass % was added. After further reflux for 30 minutes, it was naturally cooled to obtain SiO 2 The polysiloxane solution (1) whose conversion density|concentration is 12 mass %.

Synthetic example 2

[0307] In a 200 ml four-necked reaction flask equipped with a thermometer and reflux tube, PGME (28.3 g), E1 (8.20 g), E3 (19.9 g) and E5 (20.0 g) were mixed to prepare a solution of the alkoxysilane monomer. A solution prepared by mixing PGME (19.1 g), water (10.8 g), and oxalic acid (1.10 g) as a catalyst was added dropwise to this solution over 30 minutes at 25° C., followed by stirring at 25° C. for 30 minutes. Then, after heating using an oil bath and refluxing for 30 minutes, the mixed solution of the methanol solution (1.20g) and PGME (0.90g) with the content of E4 prepared beforehand of 92 mass % was added. After further reflux for 30 minutes, it was naturally cooled to obtain SiO 2 The polysiloxane solution (2) whose conversion density|concentration is 12 mass %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com