Shallow opening invisible socks and producing method of shallow opening invisible socks

A technology of invisible socks and shallow openings, applied in socks, pantyhose, clothing, etc., can solve the problems of inconvenient production and processing, complex structure, etc., and achieve the effects of simplified production and processing methods, excellent physical properties, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

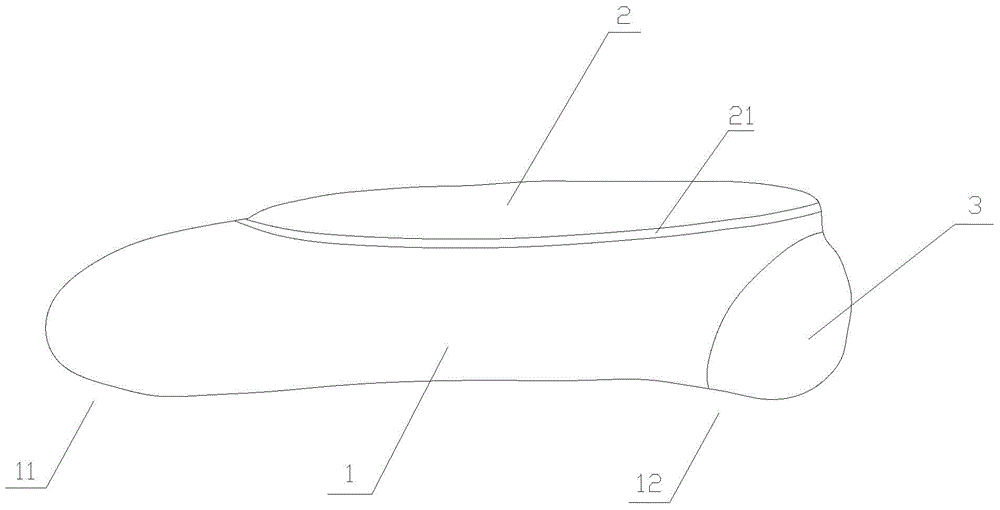

[0018] Such as figure 1 As shown, a shallow invisible sock includes a sock body 1, and an opening 2 is provided at the top of the sock body 1 for the foot to extend in. One end of the 2 opening is located near the toe 11 of the sock body 1 and the other end is located Near the heel 12, the heel 12 of the sock body 1 is provided with an anti-slip layer 3, and the sock body 1 is a one-time molding structure without shearing and splicing. During the use of the present invention, when the foot is inserted into the sock body through the opening 2, the front end of the sock body 1 covers the toes, the rear end covers the heel, and the edge of the opening 2 covers the bottom of the ankle, ensuring that the socks are worn Behind the shoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com