Elastic bed plate assembly used for bedstead

A technology of elasticity and bed boards, applied in bed frames, mattresses, applications, etc., can solve problems that affect the quality of sleep beds, muscles cannot be relaxed, and do not meet human needs, etc., to achieve stable installation, light weight, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

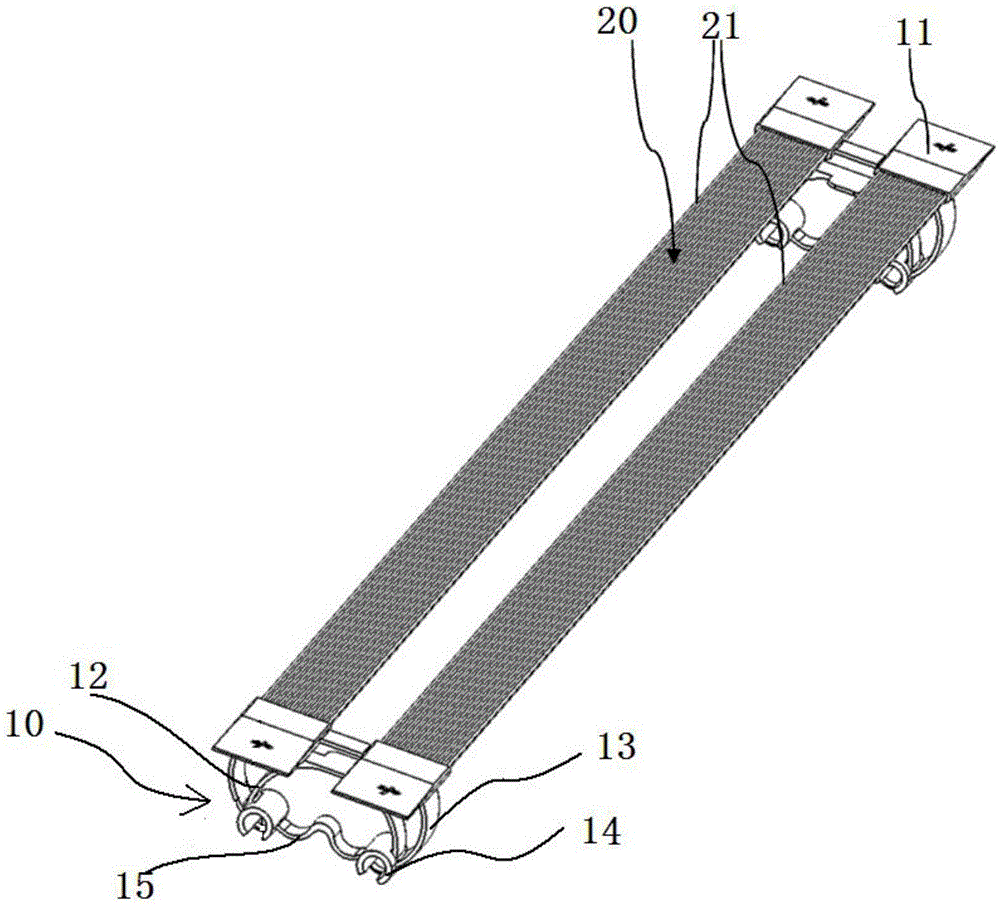

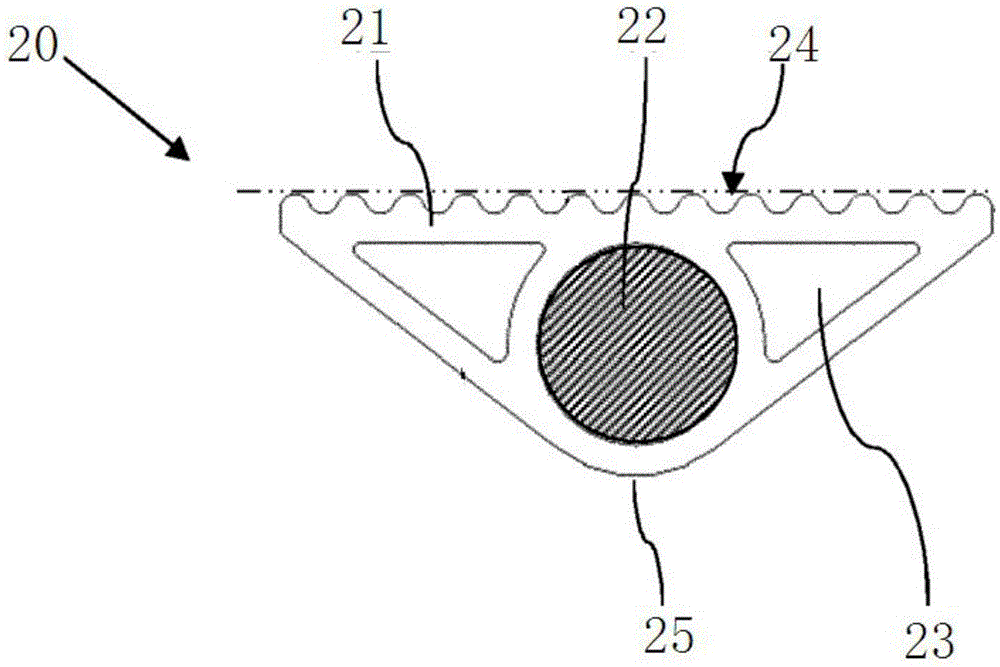

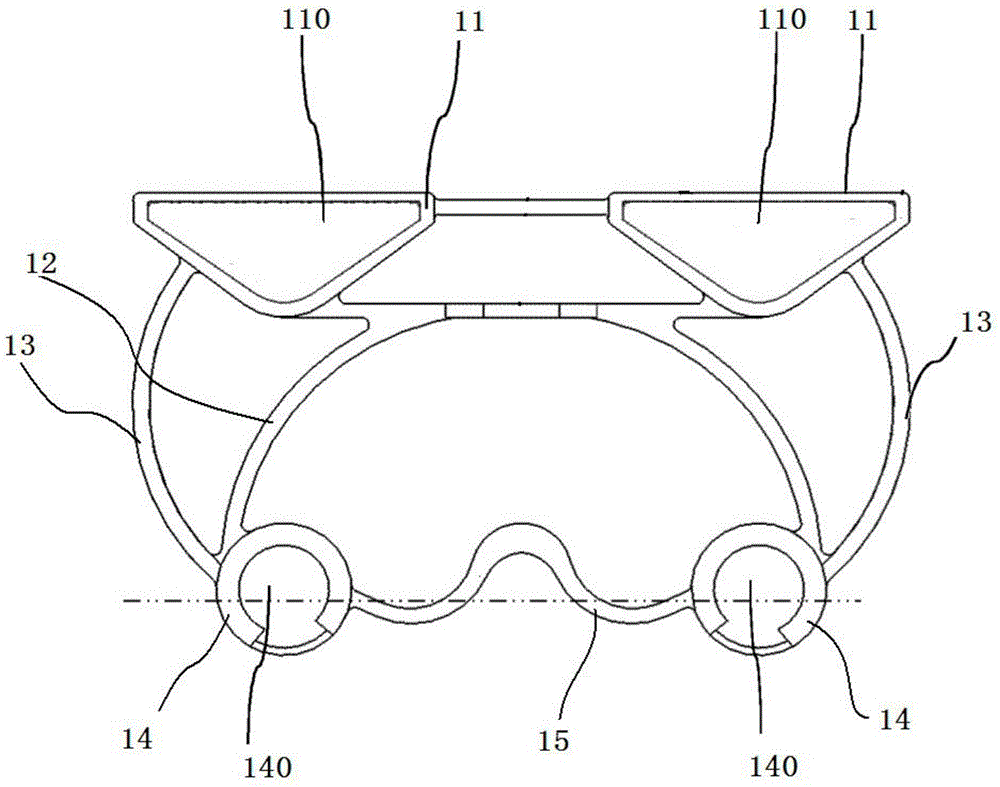

[0022] see figure 1 and figure 2 , an elastic bed board assembly for a bed frame in this embodiment, which is formed by one-time injection molding of thermoplastic materials, and includes elastic bed boards 20 and elastic connecting assemblies 10 for being installed on the two ends of the elastic bed boards 20, the elastic bed board The strip 20 includes a thermoplastic material lath body 21 and a main core member 22 arranged in the lath body 21 to play a main bearing force. The main core member 22 is made of glass fiber material, so that the lath body has elasticity and at the same time Have a certain tolerance. The upper surface of the slat body 21 is a close-fitting surface, and the said close-fitting surface is provided with anti-slip lines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com