Method for machining small-cutting-in roughing-feed integral impeller rough slot

A technology of integral impeller and processing method, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve problems such as prolonging processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A rough grooving method for integral impellers with small depth of cut and high feed: use a special flying saucer milling cutter to process deep cavity grooves with a depth of 3-5 times the cutter radius, each cut depth is 1-4.5mm, and each tooth The dosage is 0.5-1mm;

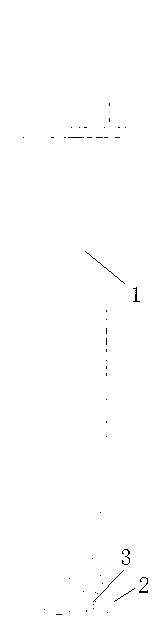

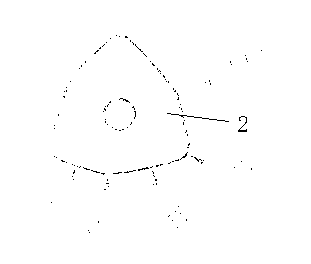

[0030] The special flying saucer milling cutter meets the following requirements: it is composed of a cutter bar 1, a blade 2, and a fixing screw 3, and the blade 2 is positioned at the front end of the cutter bar 1 and is fixed on the cutter bar 1 by the fixing screw 3; The flying saucer milling cutter has three heads, the blade 2 has three pieces, and the blade 2 is triangular. Specifically, the main body profile of the blade 2 is a triangle, such as image 3 shown.

[0031]

[0032] In the rough grooving processing method of the integral impeller with small depth of cut and high feed, the depth of each cut is 1.5-4 mm, and the feed rate per tooth is preferably 0.55-0.8 mm.

[0033] In the rough g...

Embodiment 2

[0039] This embodiment is specifically implemented on the basis of embodiment 1, and the specific requirements different from embodiment 1 are as follows:

[0040] Titanium alloy deep cavity processing: The workpiece to be processed is an axial-flow integral impeller, and the processing part is the cavity between the blades. The processing depth is 170mm, and the tool is processed by a special milling cutter with a diameter of 40mm. The processing parameters are as follows: the cutting line speed is 63m / min, the feed rate per tooth is 0.5mm / tooth, the calculated tool speed is 500 rpm, the feed rate is 750mm / min, and the depth of cut for each layer is 1.2mm. The toolpath of the tool can be found in the appendix Figure 7 . Due to the large feed rate per tooth, the machining cooling method has a great impact on tool life. In order to prolong tool life, it must be equipped with an internal powerful cooling system.

[0041]

Embodiment 3

[0043] This embodiment is specifically implemented on the basis of embodiment 1, and the specific requirements different from embodiment 1 are as follows:

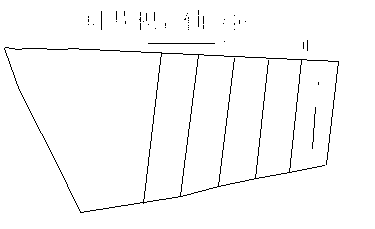

[0044] Die steel deep cavity processing: the workpiece to be processed is an extrusion die, the processing part is a cavity, the processing depth is 130mm, and the diameter of the tool is 40mm. Special milling cutter is used for processing. Processing example see attached Figure 8.

[0045] The processing parameters are as follows: the cutting line speed is 80m / min, the feed rate per tooth is 0.7mm / tooth, the calculated tool speed is 700 rpm, the feed rate is 140mm / min, and the depth of cut for each layer is 1.0mm. Due to the large feed rate per tooth, the machining cooling method has a great impact on tool life. In order to prolong tool life, it must be equipped with an internal powerful cooling system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com