Operation cutting training system and method based on force feedback and used for surgical robot

A surgical robot and training system technology, applied in the direction of surgical robots, etc., can solve the problems of poor real-time performance of the finite element model structure, and achieve the effects of improving real-time performance, effectiveness, fidelity, and execution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] A surgical cutting training system based on force feedback for surgical robots, including the following modules:

[0030] 3D virtual environment and 3D surgical instrument model building module, 3D virtual soft tissue model building module, model reading and positioning module, cutting tool and model collision detection module, force feedback module, classification and cutting module;

[0031] (1) The 3d virtual environment and 3d surgical instrument model building blocks are used to construct the 3d virtual environment and the 3d surgical instrument model of the surgical cutting training system;

[0032] The 3D virtual environment and 3D surgical instrument model building modules are the basic modules of the surgical cutting training system. The environment construction of the surgical cutting training system is completed, providing a three-dimensional 3D training environment for operating users, improving the fidelity of system training, and realizing the whole system....

specific Embodiment approach 2

[0042] The 3D virtual environment and 3D surgical instrument model construction modules described in this embodiment include a 3D surgical instrument model construction submodule and a 3D virtual environment construction submodule;

[0043] The 3D surgical instrument model building sub-module is used to build a 3D surgical instrument model; the 3D surgical instrument model building sub-module is based on the size of the real surgical instrument shape, using 3dmax to build a model and mesh division method to build a 3D surgical instrument model;

[0044] The 3D virtual environment construction sub-module is used to construct the 3D virtual environment of the surgical cutting training system, including horizontal plane setting, lighting, background, visual orientation, etc.; the 3D virtual environment construction sub-module uses VC++ and OpenGL technology to construct the 3D virtual environment of the surgical cutting training system environment.

[0045] Other modules and para...

specific Embodiment approach 3

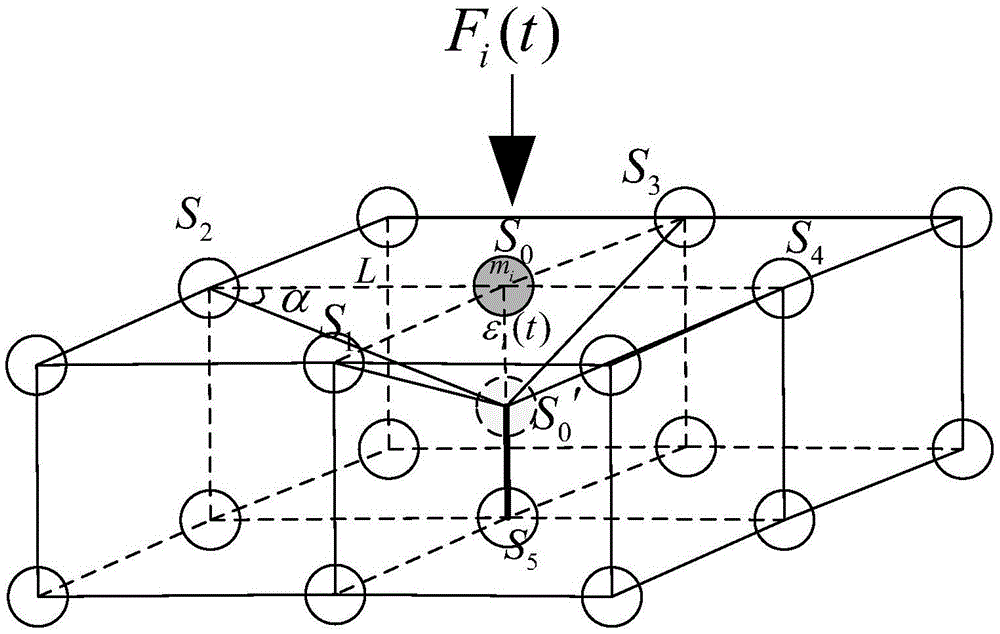

[0046] The 3D virtual soft tissue model described in the construction module of the 3D virtual soft tissue model in this embodiment utilizes a layered filling ball structure, arranges the positions of the balls according to the contour of the soft tissue, and sets different ball radii according to different positions; the balls adopt a viscoelastic structure Connected, so that the 3D virtual soft tissue model has similar performance characteristics to the real soft tissue viscoelasticity. In the process of virtual surgery training, the effect measurement after training depends on the proficiency and accuracy of the operation; the accuracy is determined according to the accuracy of the model in the system; the 3D virtual soft tissue model in the 3D virtual soft tissue model building block is the operation of the entire system Objects are the core part of the system.

[0047] Other modules and parameters are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com