Driving method of mini inertial gear box and mini inertial gear box

A driving method and tooth box technology, applied in the transmission of toys, entertainment, toys, etc., can solve the problems of insufficient power output, inability to apply to small toy cars, and inability to satisfy players, etc., to achieve compact internal structure and small volume , the effect of meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

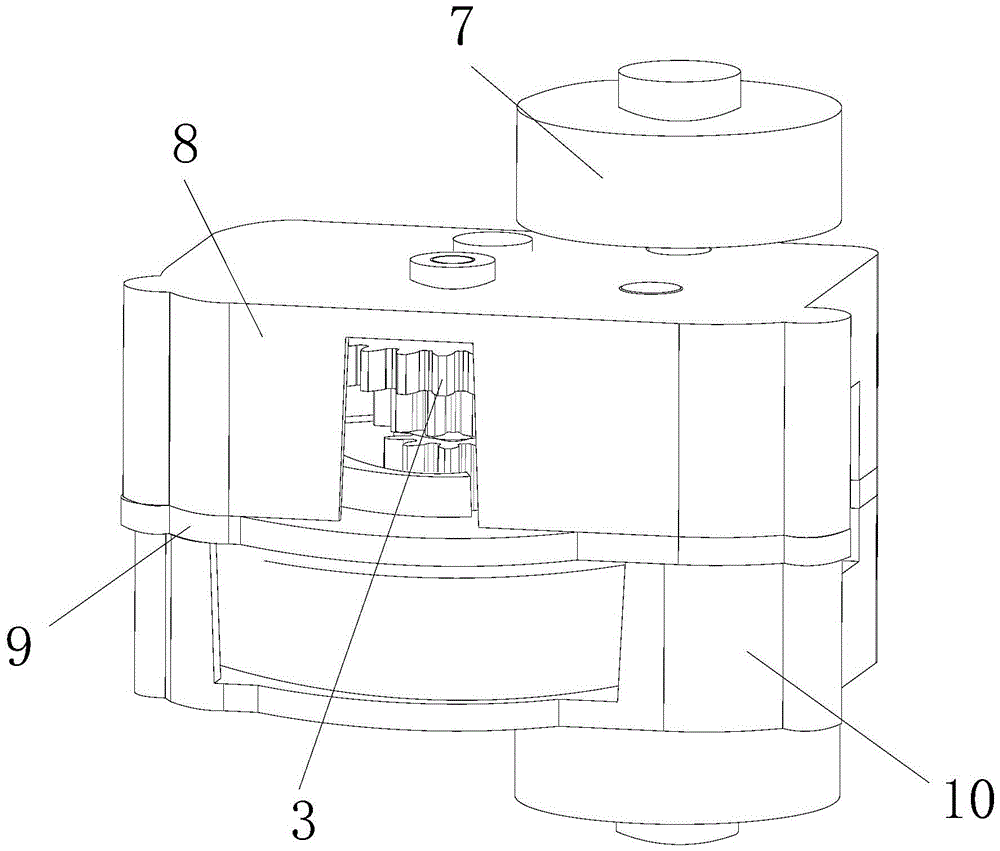

[0027] Example: see Figure 1 to Figure 3 , the present embodiment provides a driving method of a mini inertia tooth box, which includes the following steps:

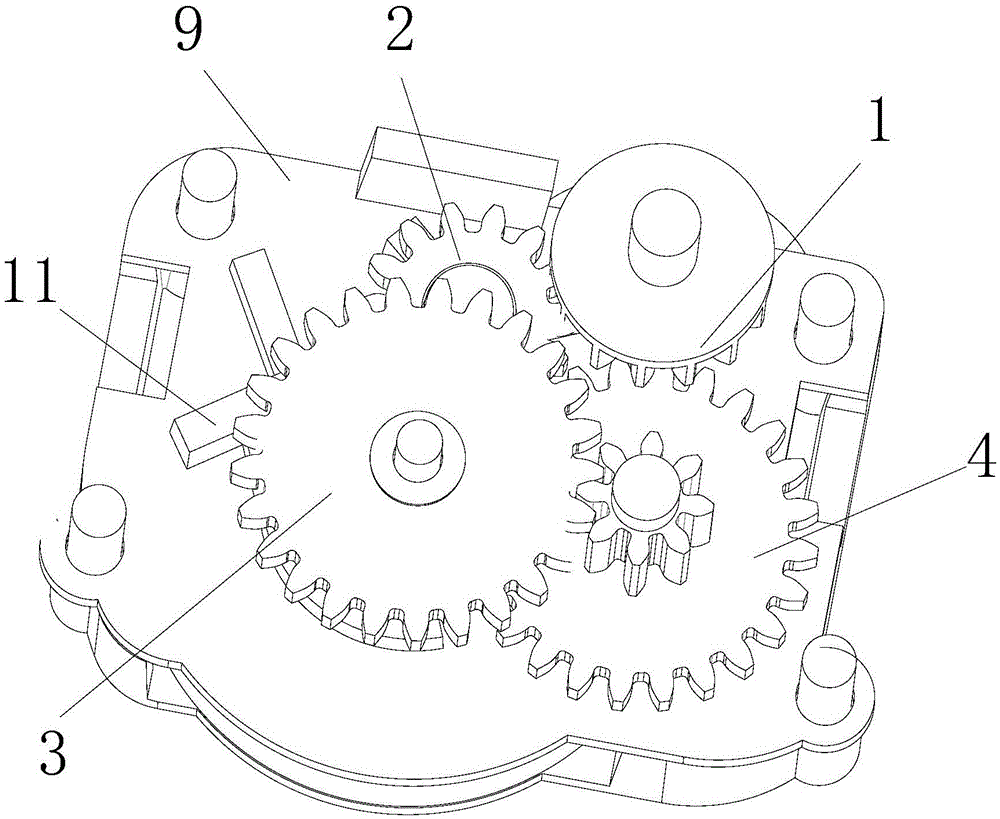

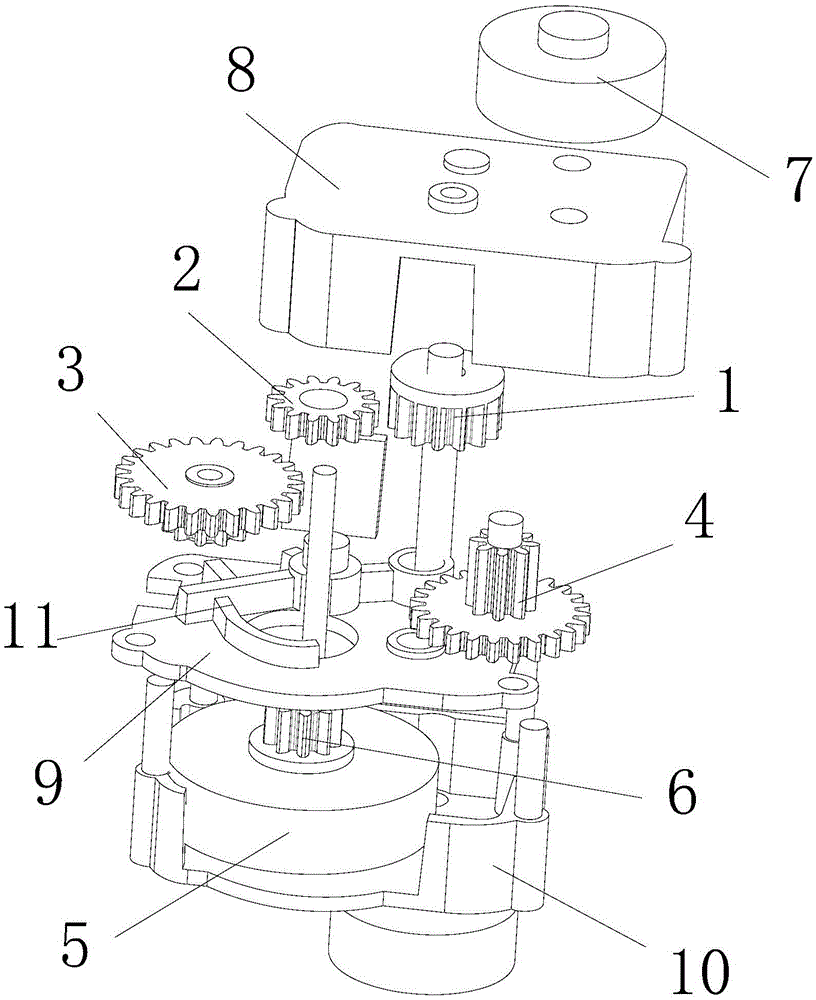

[0028] (1) Reserve power output shaft gear 1;

[0029] (2) Prepare the transmission gear set connected with the power output shaft gear 1; the transmission gear set includes the first transition gear 2, the second transition gear 3 and the third transition gear 4;

[0030] (3) Prepare the flywheel assembly, the flywheel assembly includes a flywheel 5 and a flywheel tooth 6 arranged at the upper end of the flywheel 5;

[0031] (4) Wipe the wheel 7, and the wheel 7 makes the power output shaft tooth 1 rotate, which in turn drives the first transition tooth 2, the second transition tooth 3 and the third transition tooth 4, and the third transition tooth 4 drives the flywheel tooth 6 to rotate, Thereby flywheel 5 rotates rapidly;

[0032] (5) When the rubbing of the wheel 7 is stopped, the flywheel 5 continues to rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com