Modified impregnating agent for fast-growing wood and integrated high-temperature impregnation treatment method

A treatment method and impregnating agent technology, applied in wood impregnation, pressure impregnation, impregnated wood, etc., can solve the problems of inability to realize efficient and seamless combination of impregnation treatment and high-temperature heat treatment, complicated process flow, and large energy consumption, and achieve an increase in additional Value and technical content, simple preparation process, and the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

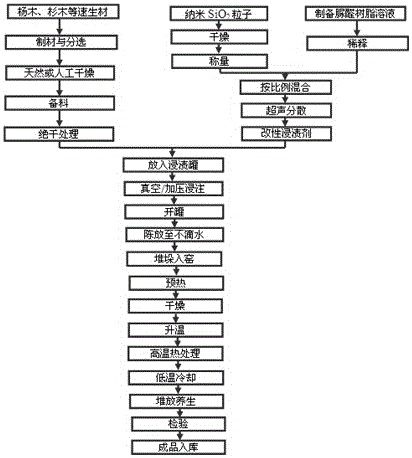

[0017] Control attached figure 2 , fast-growing wood modified impregnating agent and impregnated high-temperature integrated treatment method, comprising the following steps:

[0018] (1) Preparation of modified urea-formaldehyde resin impregnating agent:

[0019] ① Dilution of urea-formaldehyde resin solution:

[0020] The urea-formaldehyde resin solution is produced according to the conventional process, the solid content is 40%-50%, the pH value is 7.0-9.5, the viscosity is ≥20mPa·s, and the free formaldehyde content is ≤0.5%.

[0021] Because the solid content of the factory-made urea-formaldehyde resin solution is too high, the high viscosity is not conducive to the penetration of the solution into the wood during impregnation. Therefore, the urea-formaldehyde resin solution needs to be diluted with distilled water or clear water. The solid content is controlled at 20%-25%.

[0022] ② Nano-SiO2 drying and weighing:

[0023] Prepare hydrophilic nano-silica, molecular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com