Slewing gangplank

A rotary, wharf technology, applied in ships, cargo handling equipment, passenger handling equipment, etc., can solve the problems of shaking, low operation efficiency, unsafe, etc., and achieve the effect of stable retraction, prevention of shaking, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

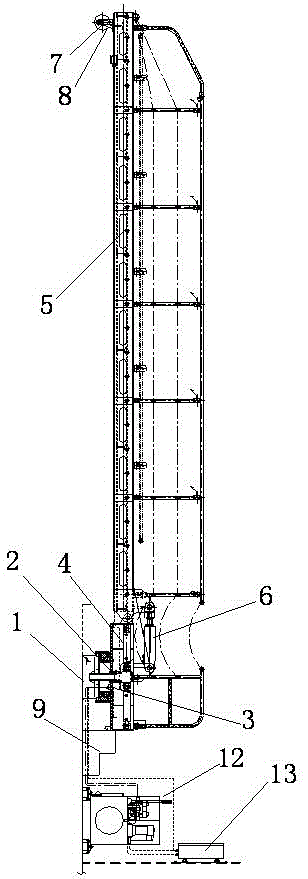

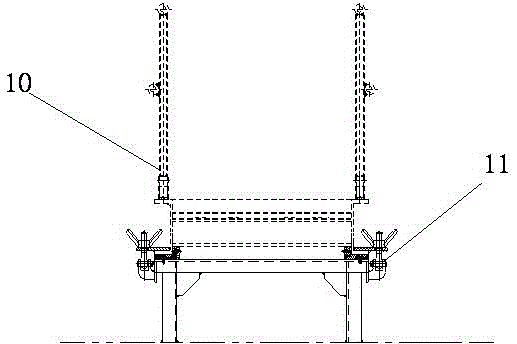

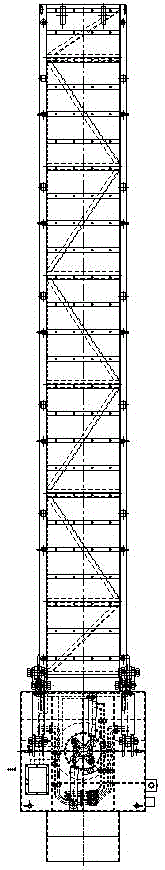

[0012] see Figure 1 to Figure 3 , the present invention relates to a rotary wharf ladder, which includes a base 1, the base 1 is arranged on the deck, the base 1 is provided with a slewing support 2, the slewing support 2 is provided with an upper platform 3, and the slewing support 2 and A rotary oil cylinder 4 is connected between the upper bearing platform 3, and the rotary oil cylinder 4 can drive the upper bearing platform 3 to rotate. One end of the upper bearing platform 3 is hinged with a ladder frame 5, and the upper bearing platform 3 and the ladder frame 5 are fixed with a luffing oil cylinder 6, the luffing oil cylinder 6 can drive the ladder frame 5 to rotate up and down, the bottom of the other end of the ladder frame 5 is provided with a universal wheel 7 and a sensor 8, and the universal wheel 7 is used to make the ladder frame 5 stand on the wharf On, the sensor 8 is an ultrasonic sensor, which sends a signal when the ladder frame 5 is placed on the wharf so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com