Full-automatic mushroom bag basket feeding machine for edible mushrooms

A fully automatic, edible fungus technology, applied in packaging, conveyors, conveyor objects, etc., can solve the problems of labor consumption, high cost, and slow efficiency, and achieve the effect of simple mechanism, easy operation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

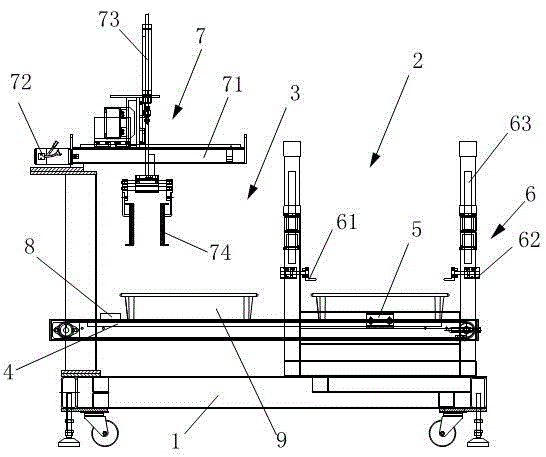

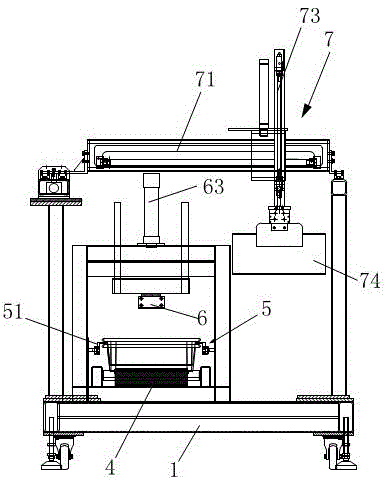

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Refer to attached Figure 1~2 , this edible fungus full-automatic mushroom packing machine of the present invention comprises frame 1, and frame 1 is provided with upper basket area 2, frame loading area 3 and conveyor belt 4, and basket 9 arrives from upper basket area 2 through conveyor belt 4 The frame loading area 3 is used for loading baskets; the upper basket area 2 is equipped with a basket locking mechanism 5 and a basket lifting mechanism 6. The basket locking mechanism 5 will block the last basket, and the basket lifting mechanism 6 will move the first basket to the penultimate one. The basket is lifted upwards to break away from the last basket, which finally arrives at the basket loading area by conveyor belt 4.

[0021] The basket loading area 3 is provided with a basket loading manipulator 7 . The basket loading manipulator 7 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com