A kind of composite arm frame whole assembly and unloading truck

It is a complete and unloading and compound technology, which can be used in cranes and other directions to solve the problems of insufficient direct force transmission path of the telescopic arm and luffing arm, limited working range, and complicated luffing mechanism, so as to achieve convenient assembly and unloading. Pallets and goods, a large working range, the effect of improving the working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

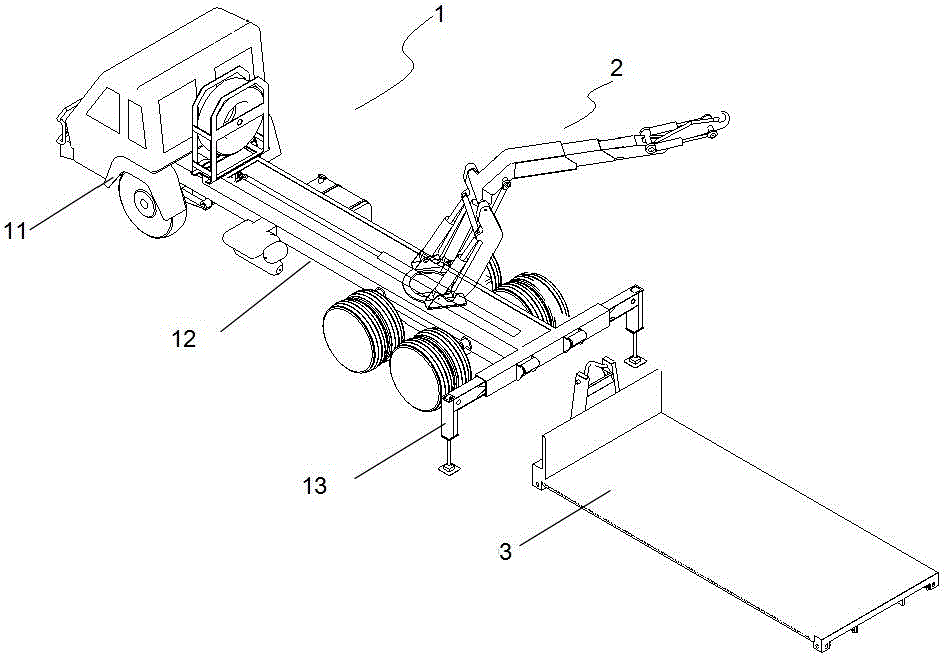

[0041] Such as Figure 1~3 As shown in the figure, a composite arm frame assembly and unloading truck can be used for the entire loading and unloading of pallet goods, and can also be used for hoisting of truck-mounted cranes. Install and unload device 2.

[0042] The Type II chassis 1 includes a carrier device 11 , a sub-frame 12 , and outriggers 13 .

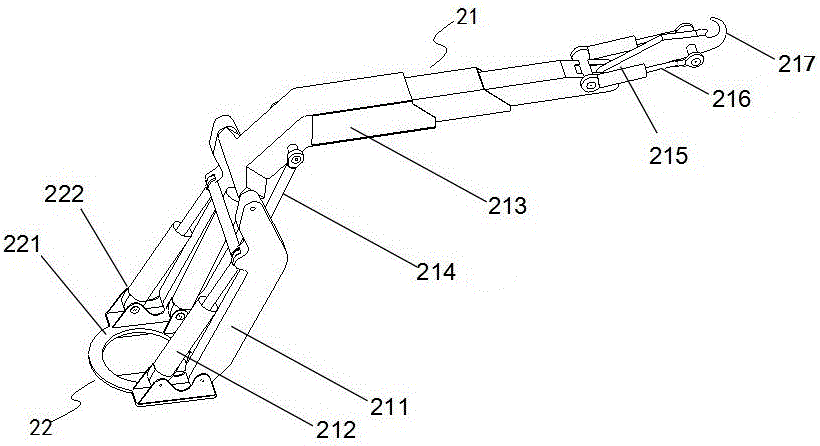

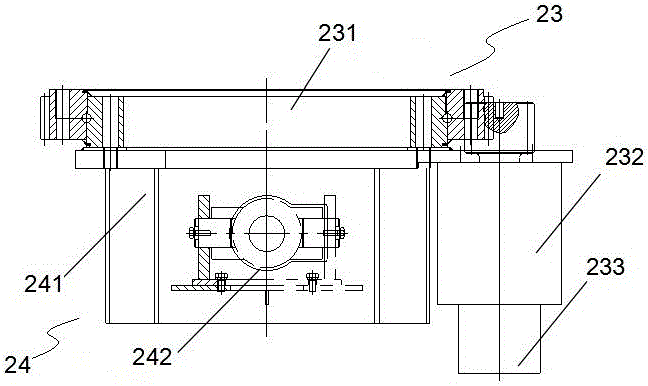

[0043] The composite boom assembly and disassembly device 2 includes a composite boom 21, a turntable system 22, a slewing support system 23 for supporting the turntable system 22, and a slide table that drives the slewing support system 23 to slide on the sub-frame 12 System 24.

[0044] The composite boom 21 includes: a luffing arm 211 hinged on the turntable system 22; one end is hinged on the turntable system 22, and the other end is connected to the luffing arm luffing cylinder 212 on the upper end of the luffing arm 211; and the luffing arm Telescopic arm 213 hinged at the upper end of 211; one end is hinged at turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com