Three-segment type linear actuator and driving assembly thereof

A technology of linear actuators and drive components, applied in transmission devices, furniture parts, lifting devices, etc., can solve problems affecting the limited height adjustment range of actuators, complicated industrial chain management, and poor versatility, so as to save axial space , compact structure, lengthened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the existing technology, on the one hand, in order to provide a larger height adjustment range, it is necessary to reduce the overlapping length of the three-section string as much as possible; on the other hand, to ensure the rigidity of the three-section linear actuator, it is necessary to increase the The overlapping length between the three-section pipe strings and the reduction of the gap between the three-section pipe strings, the height adjustment range and rigidity are a pair of contradictory indicators for the existing three-section linear actuators.

[0026] The invention proposes a new structure, which can not only realize a wide range of height adjustment, but also ensure a higher rigidity requirement, and can provide more suitable products for the market.

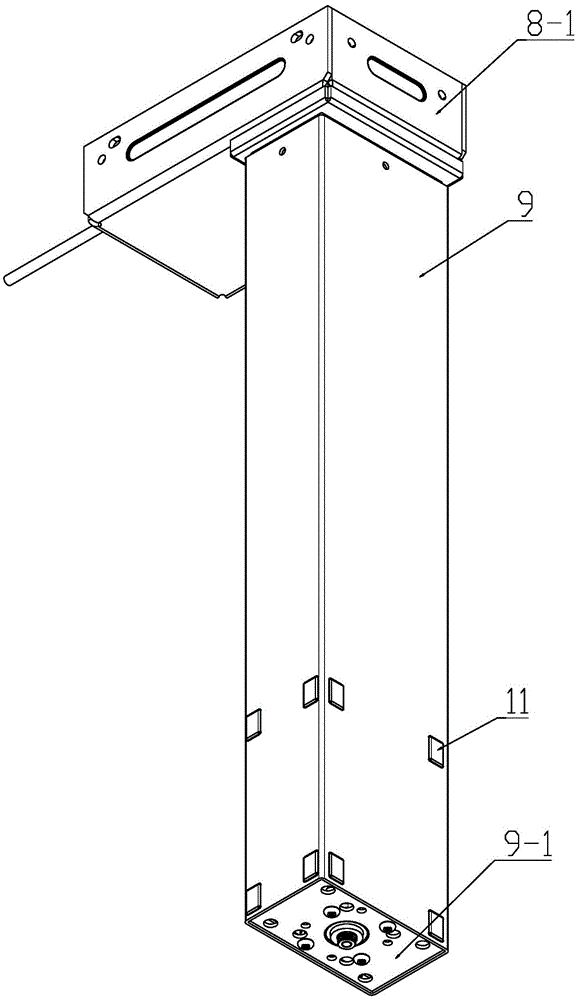

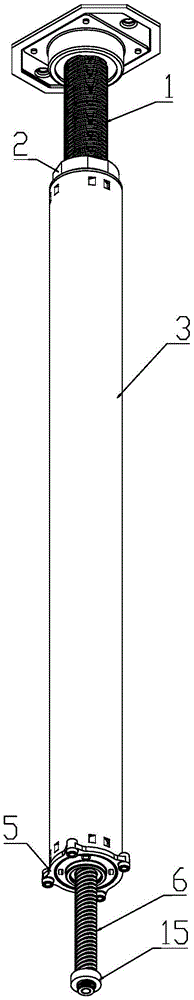

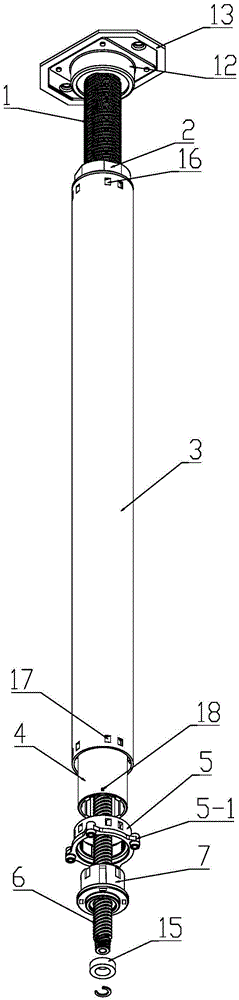

[0027] Such as figure 2 , 3 As shown in and 4, a driving assembly of a three-section linear actuator includes a hollow screw 1, a hollow screw nut 2, an outer tube 3, a fixing seat 5, a drive tube 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com