Semi-automatic mechanical luggage lifting mechanism

A lifting mechanism and semi-automatic technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of high flexibility in luggage handling, small passenger luggage quality, small compartment space, etc., and achieve manpower saving, compact structure, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

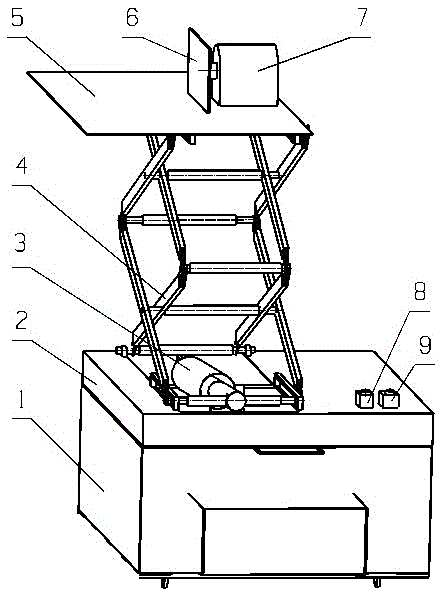

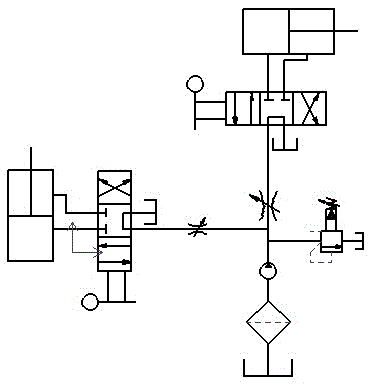

[0012] Such as figure 1 As shown, a semi-automatic mechanical luggage lifting mechanism includes a trolley 1, a lower platform 2, a first hydraulic cylinder 3, a lifting mechanism 4, an upper platform 5, a push plate 6, a second hydraulic cylinder 7, and manual vertical reversing Valve 8, manual horizontal reversing valve 9, the lower platform 2 is fixed on the trolley 1, the first hydraulic cylinder 3 and the lifting mechanism 4 are installed on the lower platform 2, and the first hydraulic cylinder 3 drives the lifting mechanism 4 to carry out Lifting movement; the upper platform 5 is fixed on the top of the lifting mechanism 4, the second hydraulic cylinder 7 is fixed on the upper platform 5, the push plate 6 is connected with the hydraulic rod of the second hydraulic cylinder 7, and the manual vertical switch Directional valve 8 and manual horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com