Forming method of liquid granite coating

A technology of granite coating and molding method, applied in separation method, chemical instrument and method, flange connection, etc., can solve the problems of high cost, reduced production efficiency, complicated operation, etc., and achieves low cost, improved production efficiency, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

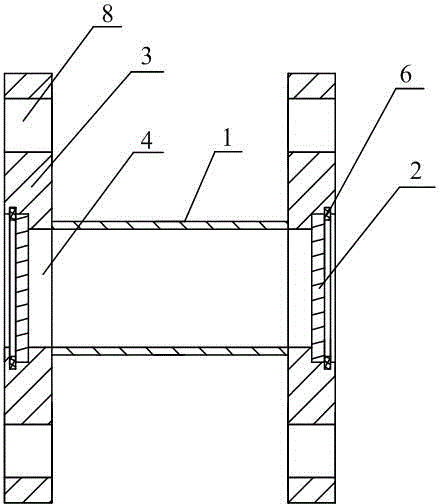

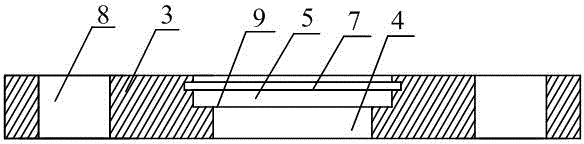

[0022] Such as figure 1 , 2 As shown, the present invention mainly consists of a formed pipe 1, which is a pipe made of metal material. Flanges 3 are respectively provided at both ends of the forming tube 1, and the flanges 3 have through holes 4 matched with the forming tube 1, and the flanges 3 are made of metal materials, and are connected with the forming tube 1. Solid one-piece structure; in order to make the liquid granite paint into granules, the flange 3 is also provided with a forming part 2, and the forming part 2 is a circular screen. In order to facilitate the connection of the forming part 2 to the flange 3, the inner wall of the through hole 4 at one end of the flange 3 relative to the forming tube 1 is inwardly recessed and forms a groove 5 matching the forming part 2, the forming part 2 After 2 is matched with the groove 5, its outer surface is then connected on the side wall of the groove 5. The bottom surface of the groove 5 is a torus with a through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com