Water-floating type ultra-thin glass substrate measuring platform

A technology of ultra-thin glass and measurement platform, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large area, warpage deformation, and inability to accurately reflect the value of warpage parameters, so as to achieve accurate warpage parameters, Reduces the effect of warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

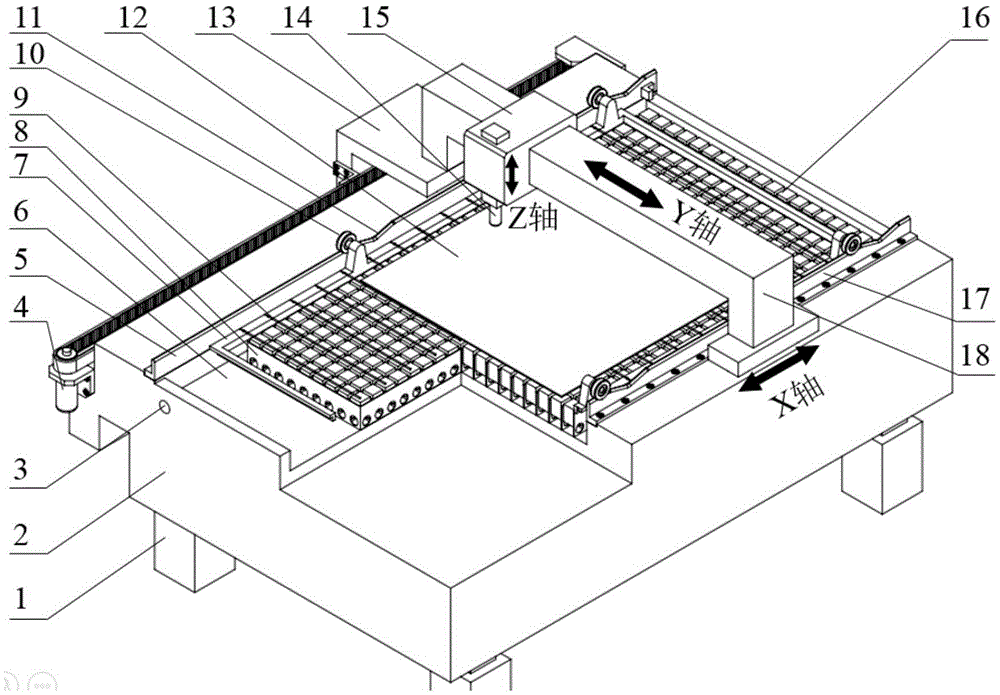

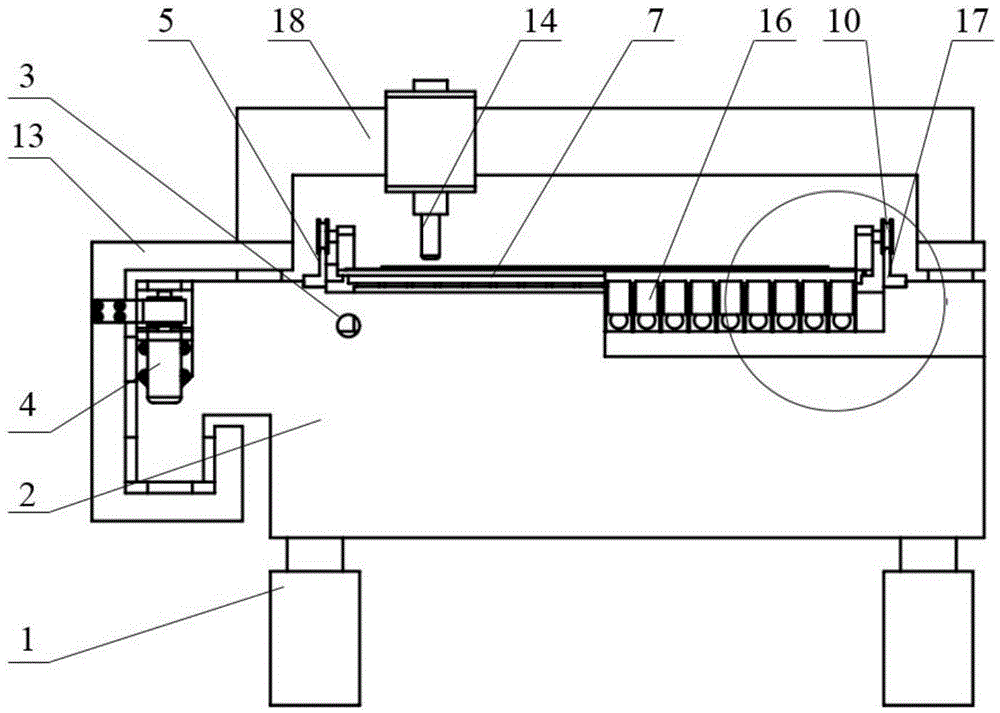

[0017] Such as figure 1 , figure 2 and image 3 As shown, a water-floating ultra-thin glass substrate measuring platform includes a measuring mechanism, a water-floating supporting mechanism and a glass carrying lifting mechanism; the measuring mechanism includes a base 2, and four Pillar 1, four pillars 1 support the entire measurement platform, above the base 2 is the structure of the gantry type coordinate measuring machine, specifically including the X-axis slide plate 13 driven by the motor 4 on the side of the base 2, the Y-axis beam 18, the Z Axis slide 15 and Z-axis slide 15 are equipped with spectral focusing probe 14, and the three motion axes all adopt air bearings, which have high motion accuracy;

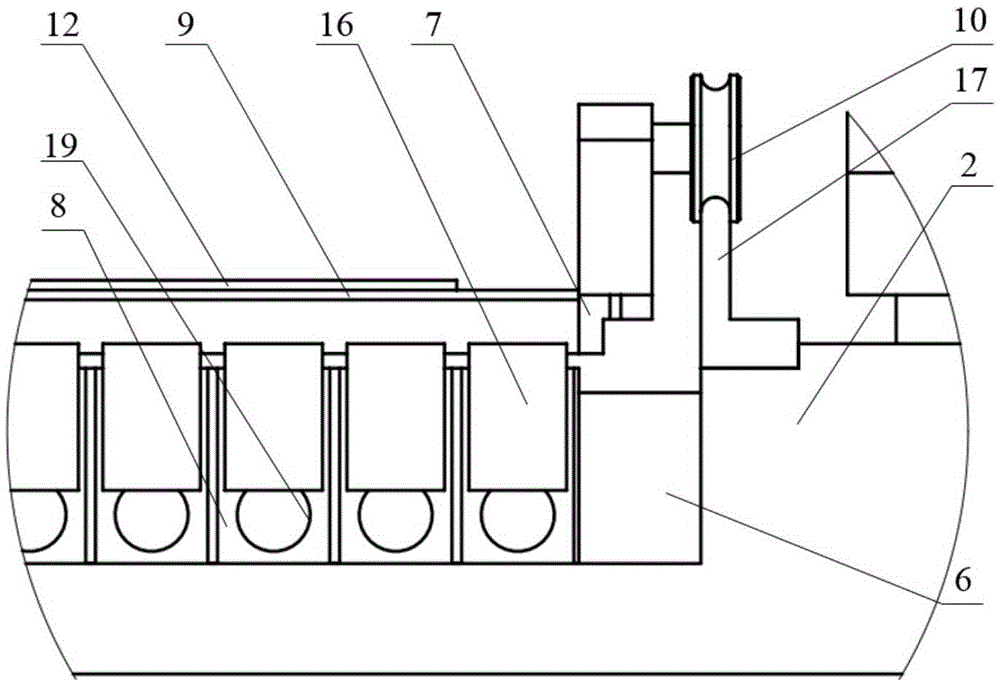

[0018] The water-floating support mechanism includes a water tank 6 arranged on the top of the base 2, and a floating block spacer 8 is arranged inside the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com