Inert gas stagnation bed activated carbon performance test system for radioactive waste gas treatment unit

An inert gas and waste gas treatment technology, applied in air quality improvement, instruments, measuring devices, etc., can solve the problems of high requirements for gas compressors, large decay tank volume, unsafe hydrogen storage for a long time, etc. The effect of preventing leakage and spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

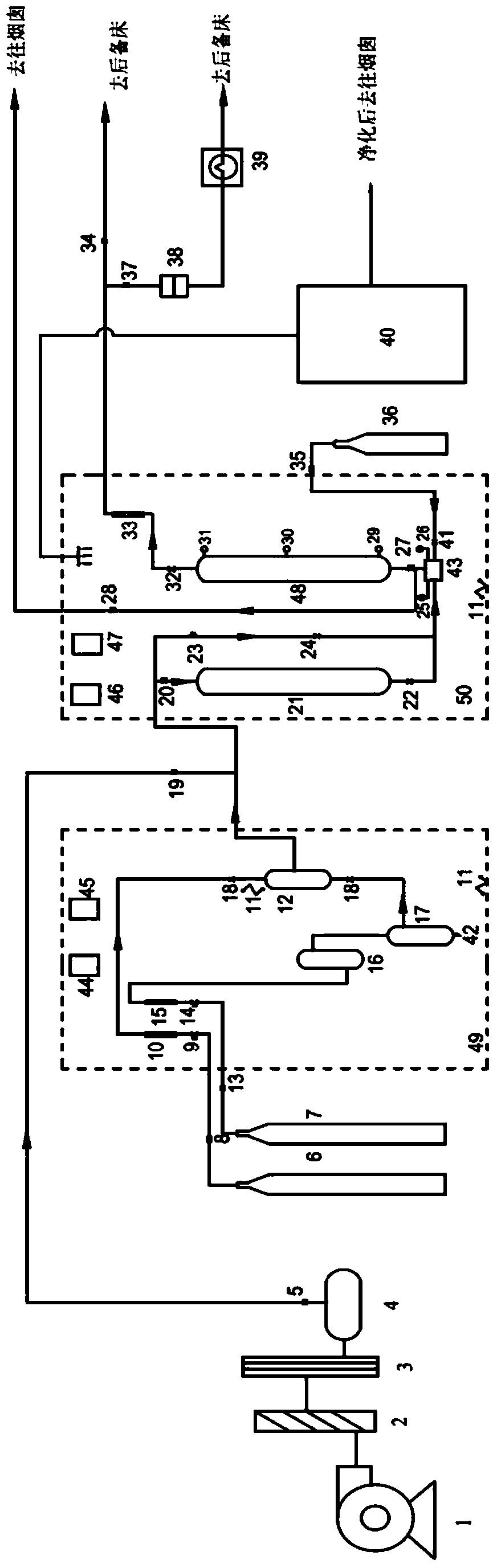

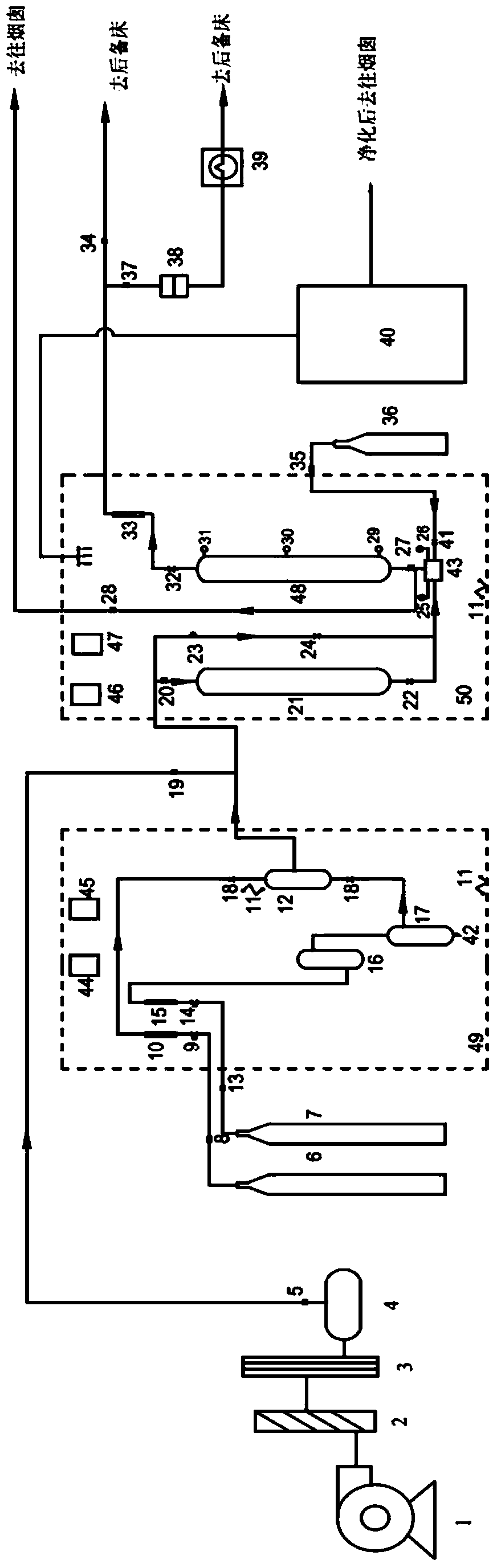

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and implementation process.

[0014] The invention provides an activated carbon performance test system for an inert gas retention bed in a radioactive waste gas treatment unit, which is used to test the performance of the retention bed for inert gas 85 Kr and 133 Retention performance of Xe. The composition of the system includes temperature, humidity, pressure and other condition parameter stabilization loops, radioactive inert gas performance test loops, and activated carbon reuse purge loops.

[0015] The structure of the system is as figure 1 As shown, it includes nitrogen supply equipment, compressed air supply equipment, guard bed, activated carbon test bed, etc., and the nitrogen supply equipment and compressed air supply equipment are respectively connected with the guard bed 21 for adsorbing organic substances in the gas. Bed 21 and radioactive inert gas so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com