Optical cable with non equilateral optical units for intensive building and manufacturing method thereof

A manufacturing method and technology of optical units, applied in optical components, light guides, optics, etc., can solve the problems of low construction efficiency and high construction cost, and achieve the effects of reducing construction costs, avoiding repeated wiring, and saving raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

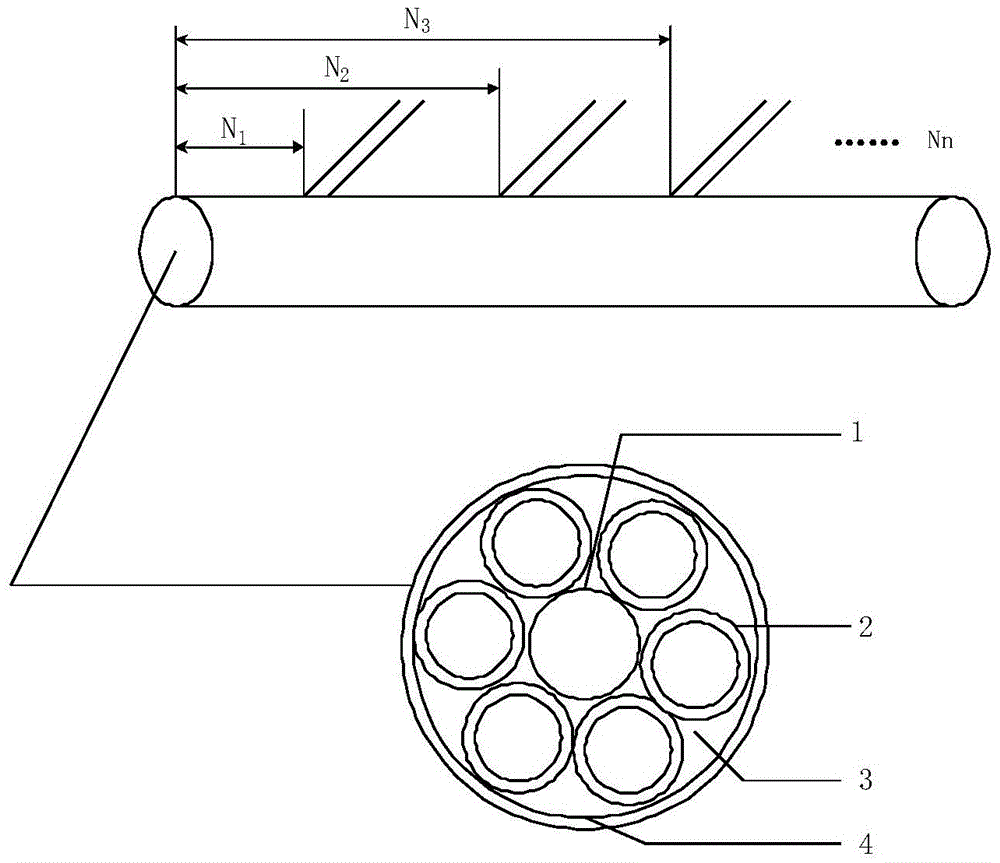

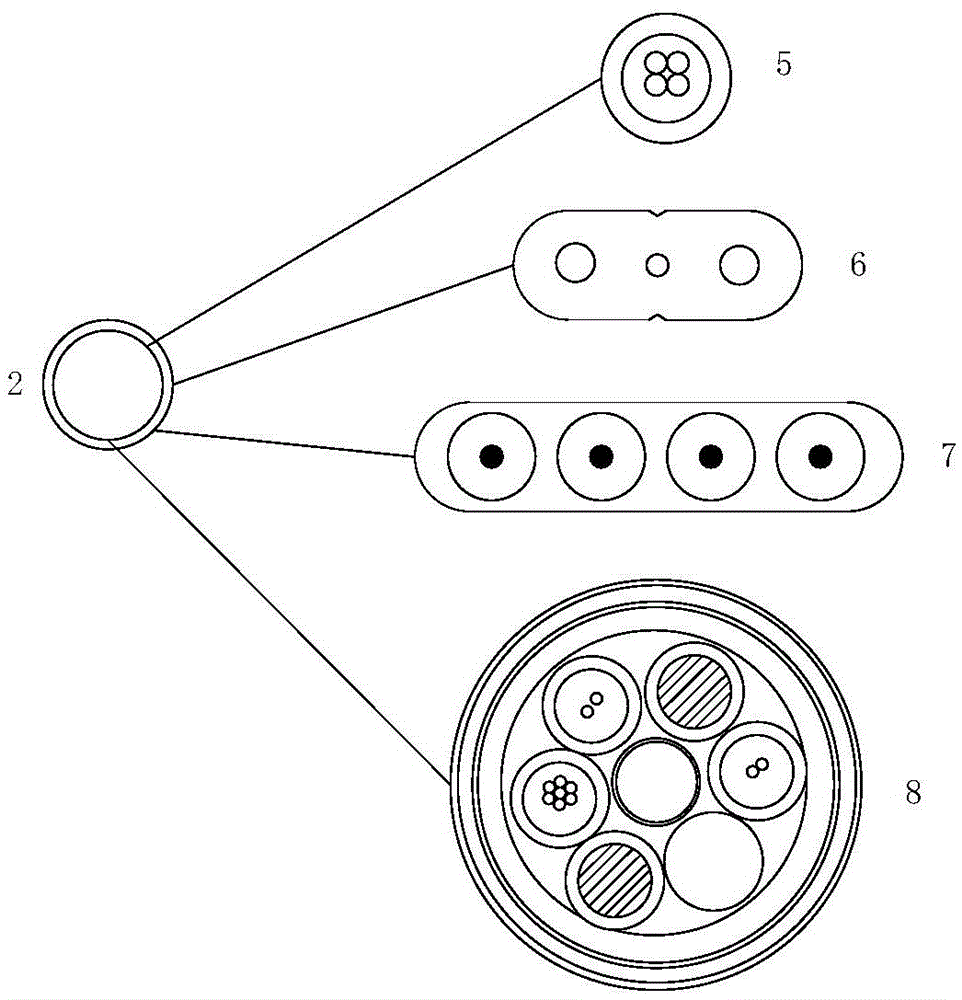

[0026] see figure 1 As shown, the non-equal-length optical unit optical cable used in dense buildings in the embodiment of the present invention includes an outer sheath 4 filled with aramid yarn 3 inside, and a central strengthening member 1 is arranged at the center of the outer sheath 4, and the center At least two groups of optical unit assemblies with different lengths are arranged around the reinforcing member 1, and each group of optical unit assemblies includes at least one optical unit 2 provided with colored optical fibers.

[0027] see figure 1 As shown, the number of light unit assemblies corresponds to the floor of the building where wiring is carried out, and the length of all light units 2 in the light unit assembly is at least greater than the height of the corresponding floor. For example, if the heights of different floors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com