Electric transformer

A technology of power transformers and transformers, which is applied in the field of high-voltage electric power, can solve problems such as restrictions on the application and promotion of power transformers, and achieve the effects of firm strength, stable reliability, vibration reduction, and stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

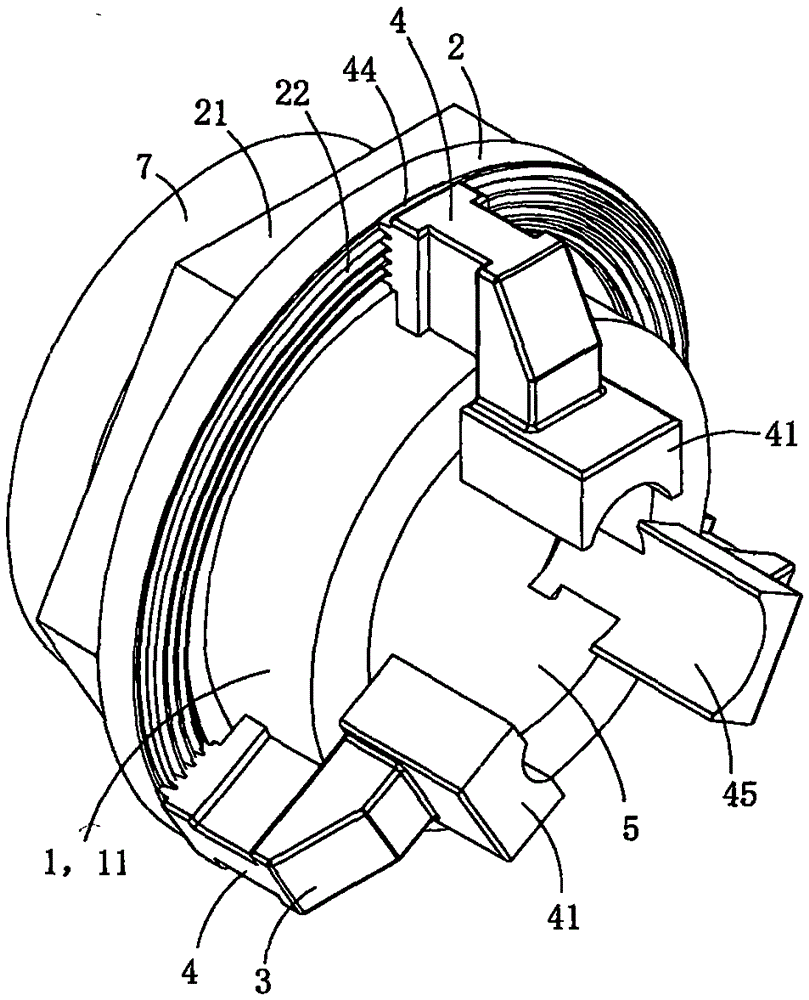

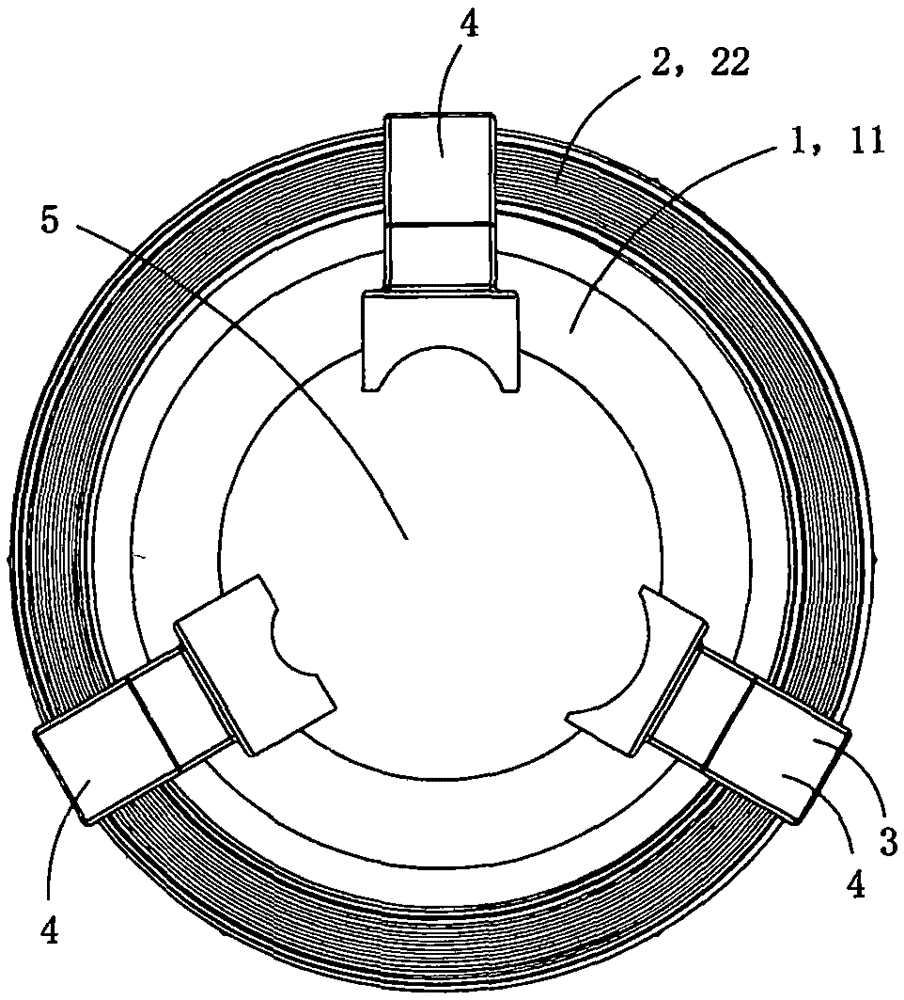

[0018] This embodiment is a power transformer, see Figure 1 to Figure 7 As shown, it includes a base body 1, a flat nut 2, a set of pressure jaw assembly 3 and a transformer 7; the pressure jaw assembly includes three pressure jaws 4; the base body is provided with a slide tube 11, a radial guide limit set on the slide tube The positioning hole 12 and the stopper 13 arranged on the outer peripheral wall of the slide tube protrude outward along the radial direction of the slide tube;

[0019] The plane nut 2 is annular, and the plane nut is slidingly sleeved on the outer peripheral wall of the base sliding tube 11; the transformer is also annular, and is fixedly sleeved on the outer peripheral wall of the base sliding tube;

[0020] The shape of the block is ring-shaped, and the block is located at the middle end of the slide tube of the base body;

[0021] The transformer and the plane nut are separated on both sides of the block, and the radial guide limit hole 12 plane nut...

Embodiment 2

[0036] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 8As shown, in order to be used as a splicing clamp for insulated power cables in this embodiment, a plurality of punctures 42 are also provided on the inner wall of the pressing plate. The piercing protrudes radially inwardly along the base slide tube 11 . The existence of puncture can effectively connect power without stripping the insulated power cables. Embodiment 1 can not be provided with puncture because what is connected is bare wire.

[0037] Each puncture is made during casting; in practice, the puncture can also be made in other ways; for example, a plurality of installation slots are provided on the inner wall of the pressure plate part, and then the puncture pieces made by punching are embedded In a corresponding mounting slot, the puncture piece includes a mounting portion and a stabbing blade, the mounting portion is embedded in the mounting slot, and the stabbing blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com