High-cooling-efficiency FPC board used for camera module group and manufacturing method thereof

A camera module, heat dissipation efficiency technology, applied in circuit thermal devices, printed circuit manufacturing, flexible printed circuit boards, etc., can solve the problem that the heat dissipation effect of the substrate is not too ideal, and achieve the effect of reducing accumulated heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

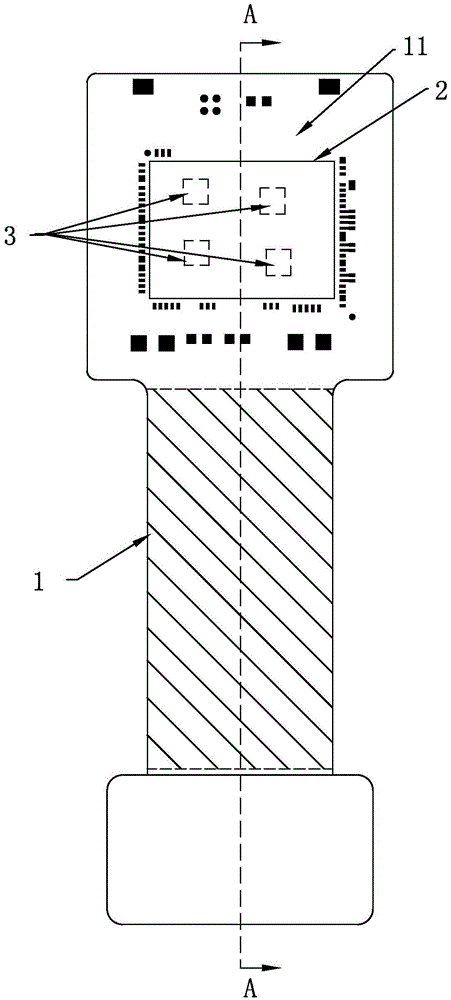

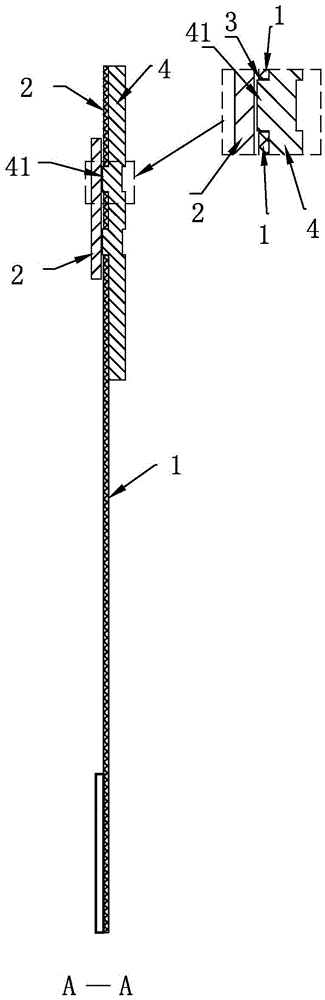

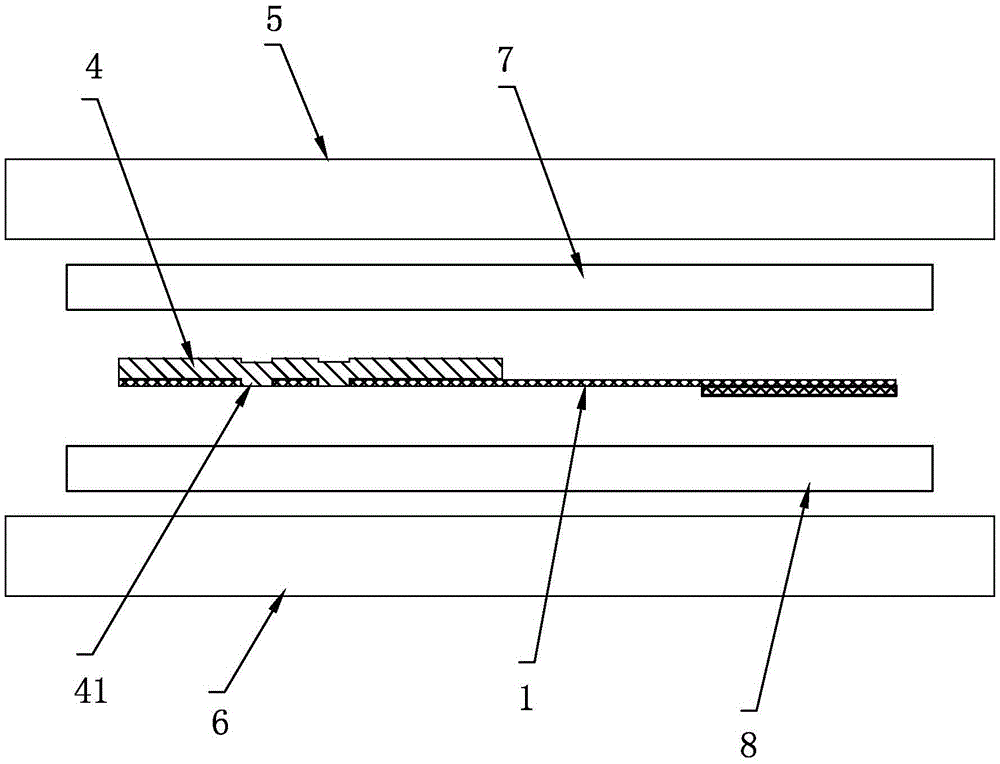

[0029] Such as figure 1 , 2 As shown, the high heat dissipation efficiency of the present invention is used for the FPC board of the camera module. In the area (also known as the circuit board area 11) where the chip 2 is mounted on the FPC soft board 1, a number of holes passing through the FPC soft board 1 are arranged. The through hole is referred to as the window hole 3. At the same time, the strength of the FPC soft board 1 at the place where the chip 2 is installed is installed on the back of the FPC soft board 1 (that is, the side where the chip 2 is mounted on the FPC soft board 1 is set as the front side. , the other side of the FPC soft board 1 at that place is the back side) the steel sheet reinforcing sheet 4 is designed as a steel sheet with a boss 41, and the number of the boss 41 is the same as the number of the window holes 3.

[0030] The shape of the window hole 3 is not limited, it can be square, regular polygon, regular trapezoid, circular or elliptical, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com