Weaving technique of ultrathin and ultra-transparent monofilament core-spun silk stockings

A technology for core-spun silk and stockings, applied in weft knitting, socks, knitting and other directions, can solve the problems of rough and hard woven surface of single-hole fiber, poor perspective and vertical feel, and poor hand-feel of single-hole fiber, so as to achieve the purpose of holding the fiber. Good resultant force and air permeability, enhanced strength and wear resistance, good perspective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

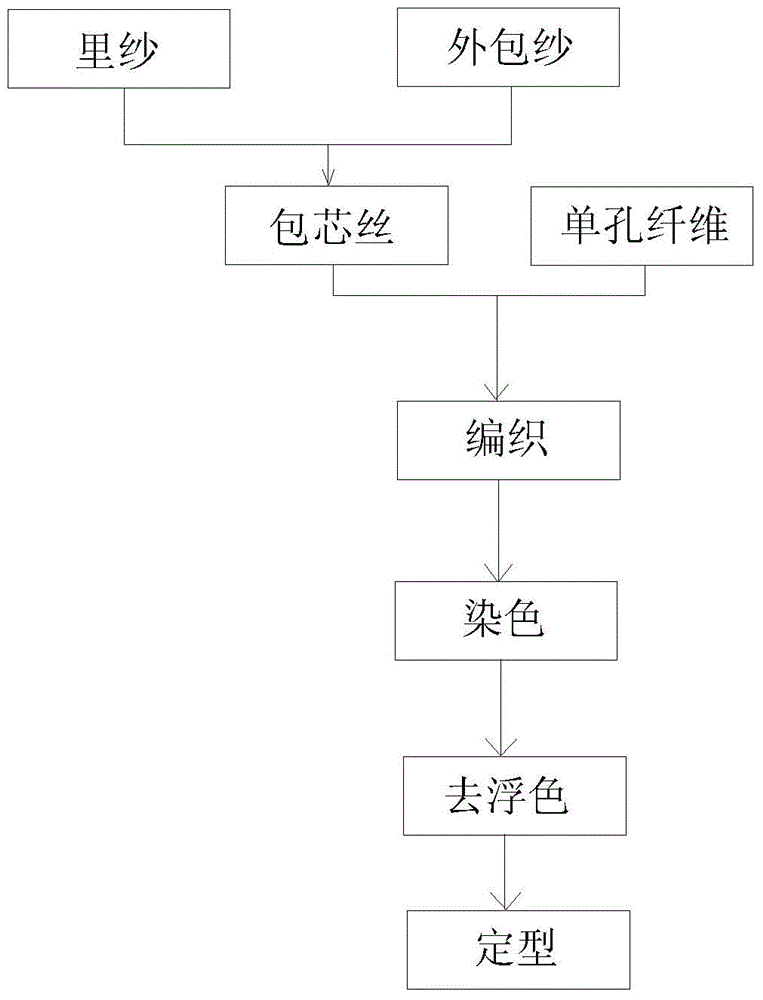

[0019] The weaving process includes the following steps:

[0020] 1) The production of core-spun yarn, using spandex as the inner yarn, elastic yarn or filament as the outer yarn, and then wrapping the outer yarn on the inner yarn on a high-speed wrapping machine to produce a twist of 1500T / M and a draft ratio of 3.5 core spun wire;

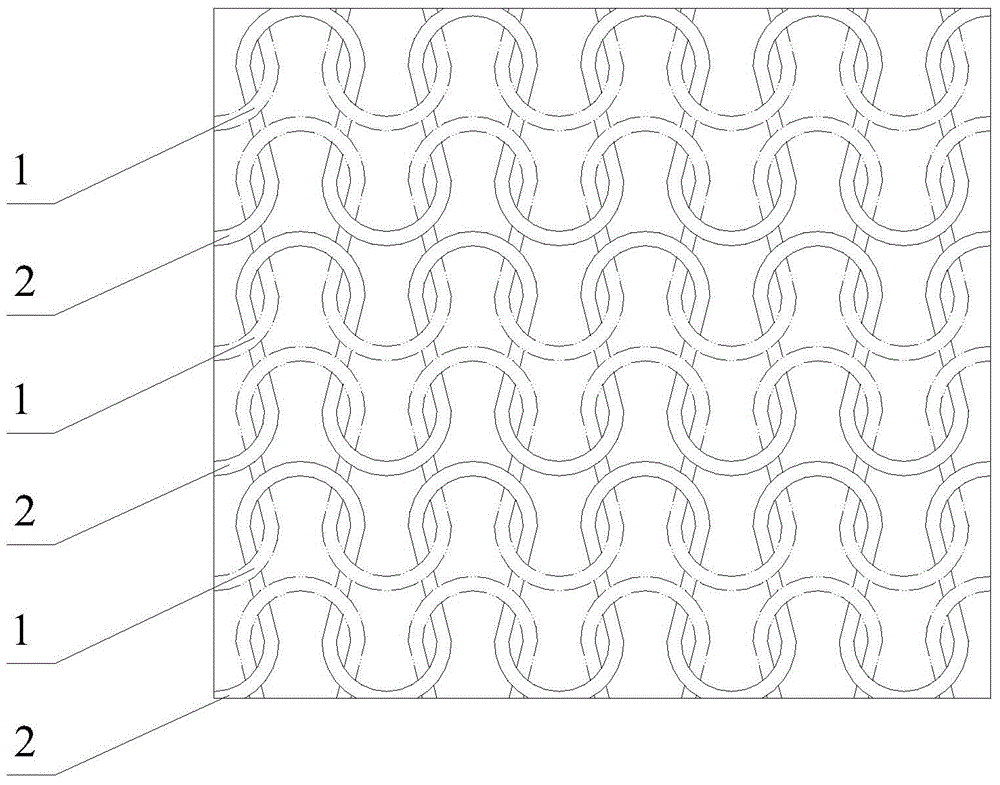

[0021] 2) Weaving, knitting the 8D / 1F single-hole fiber and core-spun yarn into a plain weft-knitted stocking preliminary product according to a one-by-one cross weaving structure. During the weaving process, the tension of the single-hole fiber and core-spun yarn is controlled In 0.12-0.15G, the tension deviation range of each thread is controlled within ±0.05G, which can effectively prevent the occurrence of poor texture during the weaving process;

[0022] 3) Dyeing: under the condition of 60°C, add dyestuff and color fixing agent to dye the finished silk stockings to make a color that meets the needs of users, and the dyeing environment is a...

Embodiment 2

[0026] The weaving process includes the following steps:

[0027] 1), the production of core-spun yarn, using spandex as the inner yarn, elastic yarn or filament as the outer yarn, and then wrapping the outer yarn on the inner yarn on a high-speed wrapping machine to produce a twist of 1750T / M and a draft ratio of 3 core spun wires;

[0028] 2) Weaving, knitting the 8D / 1F single-hole fiber and core-spun yarn into a plain weft-knitted stocking preliminary product according to a one-by-one cross weaving structure. During the weaving process, the tension of the single-hole fiber and core-spun yarn is controlled In 0.12-0.15G, the tension deviation range of each thread is controlled within ±0.05G, which can effectively prevent the occurrence of poor texture during the weaving process;

[0029] 3) Dyeing: under the condition of 55°C, add dyestuff and color fixing agent to dye the finished silk stockings to make a color that meets the needs of users, and the dyeing environment is a...

Embodiment 3

[0033] The weaving process includes the following steps:

[0034] 1) The production of core-spun yarn, using spandex as the inner yarn, elastic yarn or filament as the outer yarn, and then wrapping the outer yarn on the inner yarn on a high-speed wrapping machine to produce a twist of 2000T / M and a draft ratio of 2.5 core spun wire;

[0035] 2) Weaving, knitting the 8D / 1F single-hole fiber and core-spun yarn into a plain weft-knitted stocking preliminary product according to a one-by-one cross weaving structure. During the weaving process, the tension of the single-hole fiber and core-spun yarn is controlled In 0.12-0.15G, the tension deviation range of each thread is controlled within ±0.05G, which can effectively prevent the occurrence of poor texture during the weaving process;

[0036] 3) Dyeing: under the condition of 50°C, add dyestuff and color fixing agent to dye the finished silk stockings to make a color that meets the needs of users, and the dyeing environment is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Twist | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com