A biological treatment reactor for organic waste gas and its use method

A technology for biological treatment and organic waste gas, which is applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of high treatment cost, poor treatment effect, poor recycling effect, etc., and achieves high recycling rate and simple structure. , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

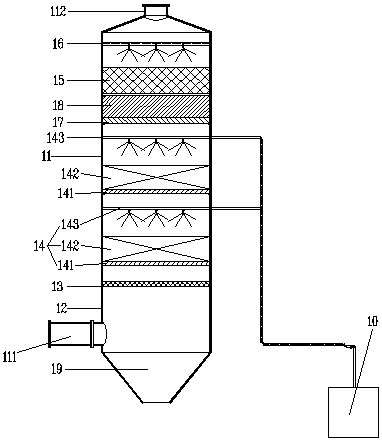

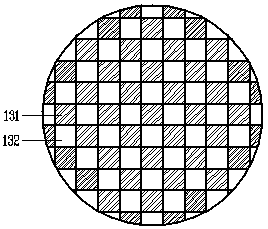

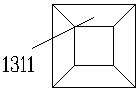

[0024] A biological treatment reactor for organic waste gas, including the main body of the reactor, as attached figure 1 As shown, the reactor body includes a shell 11 and a liquid collection area 19, a gas distribution area 12, a gas distribution plate 13, at least one packing unit 14, a net plate 17, and a dust collection packing area 18 arranged in the shell 11 from bottom to top. , a demisting layer 15 and a flushing structure 16 . Wherein, the packing unit 14 includes a perforated plate 141, a packing area 142, and a microbial rinsing structure 143 arranged in sequence from bottom to top, an air inlet 111 is provided on the housing 11 below the gas distribution area 12, and an air outlet is provided on the top of the housing 11 112. The washing structure 16 communicates with the microbial eluent pool near the outlet of the bio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com