Pipe fitting opening finishing mold

A technology for molds and pipe fittings, applied in the field of molds for the whole mouth of pipe fittings, can solve the problems of inaccurate control of manpower, inability to complete the mouth of the pipe fittings, uneven pressure force, etc., so as to avoid uneven distribution of force, ensure the quality of the whole mouth, The effect of enhancing the strength of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

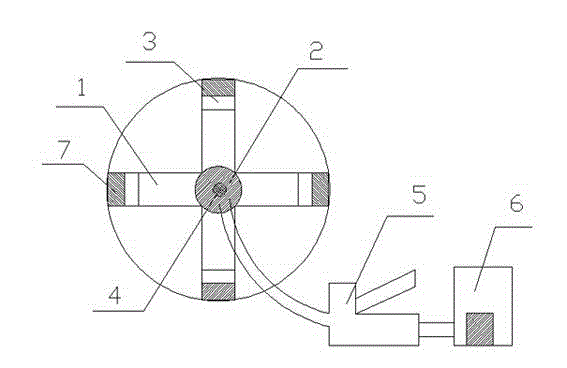

[0011] A mold for the integral mouth of pipe fittings, comprising an integral support block 1 and power equipment, the integral support block 1 is located on the mold, the power equipment and the integral support block 1 are connected to each other, the integral support block 1 is cylindrical, and the integral support The block 1 is connected with the mold through a fixed pin, and a central fixed shaft 2 is set in the middle of the whole mouth support block 1, which is made of nickel alloy. The power equipment is controlled by pneumatic equipment, and the whole mouth support block 1 is equipped with a pressure return The chip 3 and the central fixed shaft 2 are provided with a pressure sensor 4. The pressure return chip 3 is connected to the pressure sensor 4. The pressure sensor 4 is connected to the pneumatic equipment to control the opening of the mold. The power equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com