coconut cutter

A cutting machine and coconut technology, applied in metal processing and other directions, can solve the problems of uneven incision, the appearance and quality of imaged coconut processed products, and low cutting efficiency, and achieve the effect of convenient operation, simple structure and smooth cutting incision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

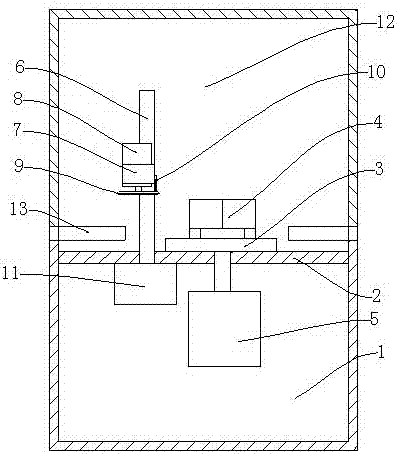

[0018] Such as figure 1 , figure 2 Shown, the coconut cutting machine described in the present embodiment, it comprises frame 1, and the upper surface of frame 1 is work platform 2, is provided with rotating disk 3 on work platform 2, is rotationally connected between rotating disk 3 and work platform 2, On the turntable 3, a fixture 4 is arranged; on the working platform 2 at the side of the turntable 3, a column 6 is arranged, and on the column 6, a No. 1 electric motor 8 vertically downward is arranged through a connector 7, and on the No. 1 motor 8 A cutting blade 9 is arranged on the output shaft, and the column 6 is connected to the connecting piece 7 in rotation; an arc-shaped baffle 10 is arranged on the No. 1 motor 8, and the arc-shaped baffle 10 and the cutting blade 9 are connected There is a gap between them, and the distance between the outer wall of the arc-shaped baffle 10 and the outer circumference of the cutting blade 9 is the same on any radius.

[0019] ...

Embodiment 2

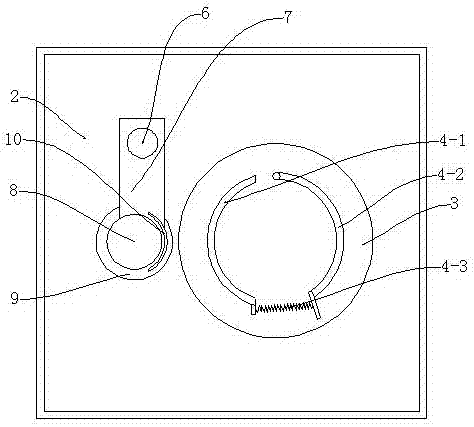

[0023] The coconut cutting machine that present embodiment describes, it comprises frame 1, and the upper surface of frame 1 is working platform 2, is provided with rotating disk 3 on working platform 2, is rotationally connected between rotating disk 3 and working platform 2, on rotating disk 3 A clamp 4 is arranged on the top; a column 6 is arranged on the working platform 2 on the side of the turntable 3, and a vertical No. 1 motor 8 is arranged on the column 6 through a connecting piece 7. A cutting blade 9 is provided, and the column 6 is rotationally connected with the connecting piece 7; an arc-shaped baffle 10 is provided on the No. 1 motor 8, and there is a gap between the arc-shaped baffle 10 and the cutting blade 9 , the distance between the outer wall of the arc-shaped baffle 10 and the outer circumference of the cutting blade 9 is the same on any radius.

[0024] The clamp 4 includes a fixed ring arm 4-1 and a rotating ring arm 4-2, wherein the fixed ring arm 4-1 ...

Embodiment 3

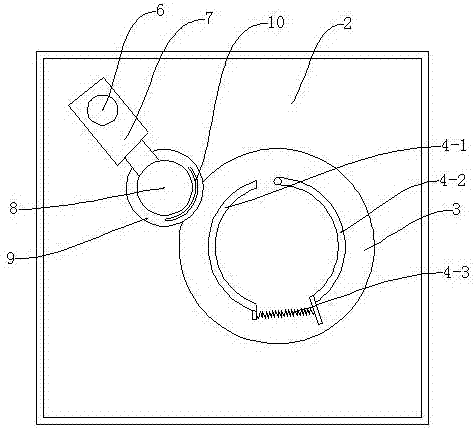

[0028] Such as image 3 Shown, the coconut cutting machine described in the present embodiment, it comprises frame 1, and the upper surface of frame 1 is work platform 2, is provided with rotating disk 3 on work platform 2, is rotationally connected between rotating disk 3 and work platform 2, On the turntable 3, a fixture 4 is arranged; on the working platform 2 at the side of the turntable 3, a column 6 is arranged, and on the column 6, a No. 1 electric motor 8 vertically downward is arranged through a connector 7, and on the No. 1 motor 8 The output shaft is provided with a cutting blade 9, the connector 7 is a telescopic cylinder, one end of the telescopic cylinder is fixed on the column 6, and the other end is connected to the No. 1 motor 8; when the telescopic cylinder stretches out for a certain distance, the cutting blade 9 pairs of clamps are realized. 4 on the cutting of the coconut. No. 1 motor 8 is provided with an arc-shaped baffle 10, there is a gap between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com