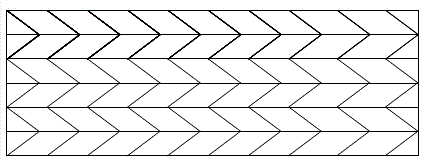

A high-elasticity rubber sheet

A rubber sheet and rubber technology, applied in the field of rubber materials, can solve the problems of uneven dispersion of additives, and achieve the effect of superior performance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

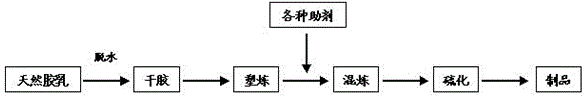

Method used

Image

Examples

Embodiment 1

[0015] The rubber sheet is made of natural rubber latex through wet mixing technology, the thickness of the rubber sheet is 1mm, and 6 layers of rubber sheets are laminated with external pressure to form a high elastic rubber sheet.

Embodiment 2

[0017] Rubber flakes are made from natural rubber latex through wet mixing technology. The thickness of the rubber flakes is 20mm. Three layers of rubber flakes are laminated with external pressure to form a high-elastic rubber sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com