A kind of preparation method of inner embossed card

A technology for embossing and cards, which is applied in the direction of chemical instruments and methods, special decorative structures, and techniques for producing decorative surface effects, etc. It can solve the problems of easy wear, difficult post-processing, uneven surface of embossed cards, and achieve the production process. Simple, flat surface, high aesthetic value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

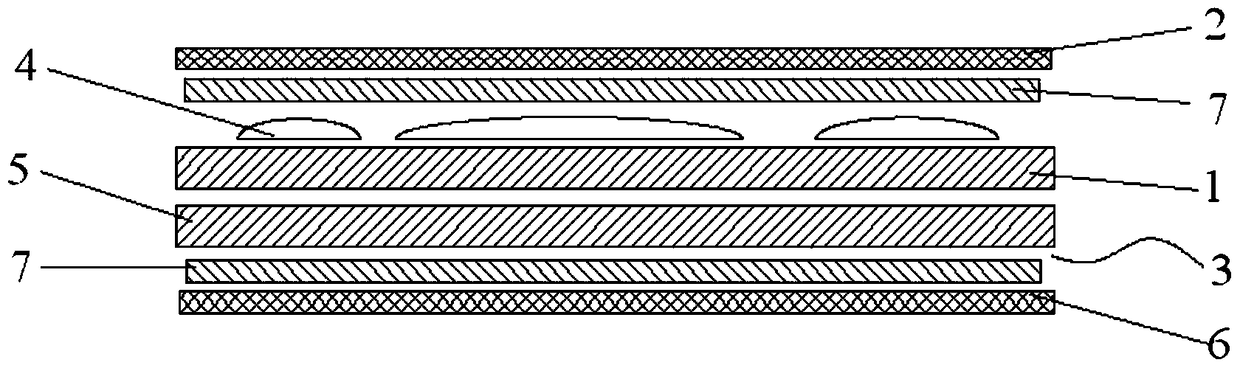

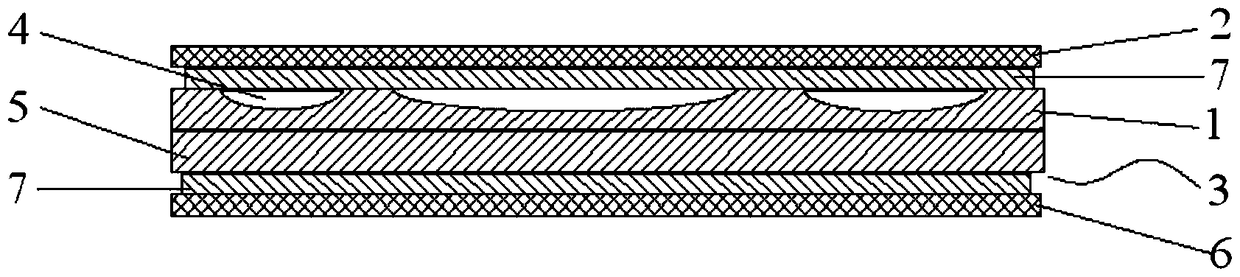

[0047] 1. Make a template

[0048] A template with a hollow relief pattern is produced by screen printing, and the mesh number of the template is 77T.

[0049] 2. Printing front core layer

[0050] Place a template with a hollow relief pattern on the upper surface of the front core layer, and then print varnish on the template, so that the varnish is transferred to the upper surface of the front core layer through the hollow template, and then place it in an oven at 60°C to dry After 3 minutes, the varnish is dried and solidified on the front core layer to obtain a front core layer with embossed patterns; among them, the material of the front core layer is laser PVC material with a thickness of 0.3mm, and the varnish composition is acrylic ester.

[0051] Print other necessary graphics on the surface of the front core layer that has already printed the embossed pattern, and combine with varnish to make the entire inner embossed card beautiful and complete.

[0052] 3. Printi...

Embodiment 2

[0058] 1. Make a template

[0059] A template with a hollow relief pattern is produced by screen printing, and the mesh number of the template is 90T.

[0060] 2. Printing front core layer

[0061] First, print other necessary graphics and texts on the upper surface of the front core layer, place a template with a hollow relief pattern on the upper surface of the front core layer that has already printed other necessary graphics and texts, and then print varnish on the template, so that the varnish passes through The hollowed-out template is transferred to the upper surface of the front core layer, and then placed in an oven at 70°C to dry for 1 minute, and the varnish is dried and solidified on the front core layer to obtain a front core layer with a relief pattern; wherein, the material of the front core layer is PVC material, the thickness is 0.4mm, and the varnish composition is chloropropenyl ester.

[0062] 3. Compression treatment

[0063] According to the order of the...

Embodiment 3

[0066] 1. Make a template

[0067] Use gravure printing to make a template with a hollow relief pattern, and the mesh number of the template is 90T

[0068] 2. Printing front core layer

[0069] Place a template with a hollow relief pattern on the upper surface of the front core layer, and then print varnish on the template, so that the varnish is transferred to the upper surface of the front core layer through the hollow template, and then place it in an oven at 80°C to dry After 4 minutes, the varnish was dried and solidified on the front core layer to obtain a front core layer with embossed patterns; wherein, the material of the front core layer was PETG material with a thickness of 0.2 mm, and the composition of the varnish was acrylic polyester.

[0070] 3. Printing back core layer

[0071] Print the necessary graphics and text on the surface of the back core layer that is about to be in contact with the back surface film, wherein the material of the back core layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com