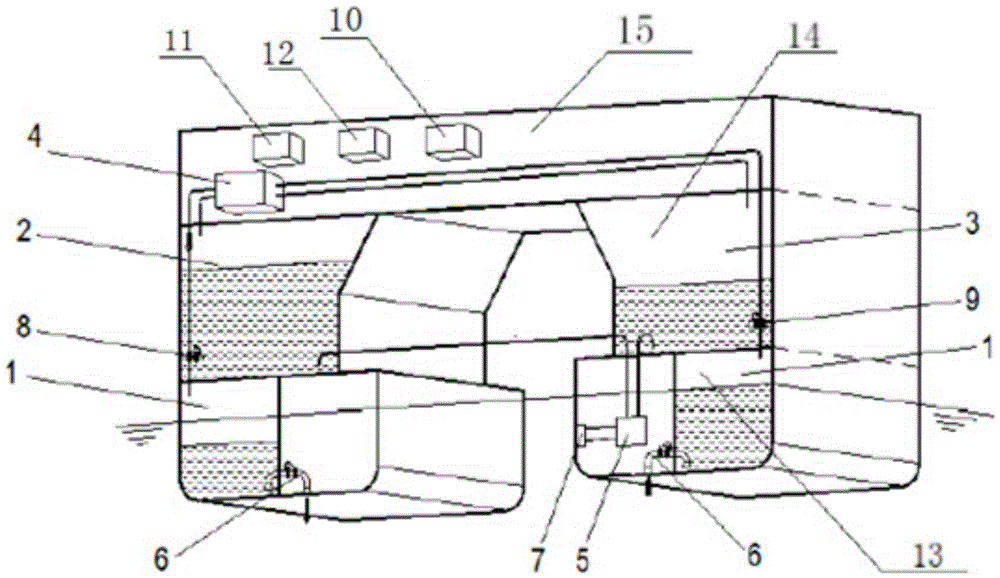

Semi-submersible type lifting platform ballast water system and operation method thereof

A lifting platform and ballast system technology, which is applied in the direction of reducing ship movement through displacement, can solve the problems of fast and efficient load adjustment of semi-submersible lifting platforms, single function of load adjustment speed, and intensified platform tilt. , to achieve the effects of easy control of load adjustment, fast load adjustment speed, and reduced platform inclination angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

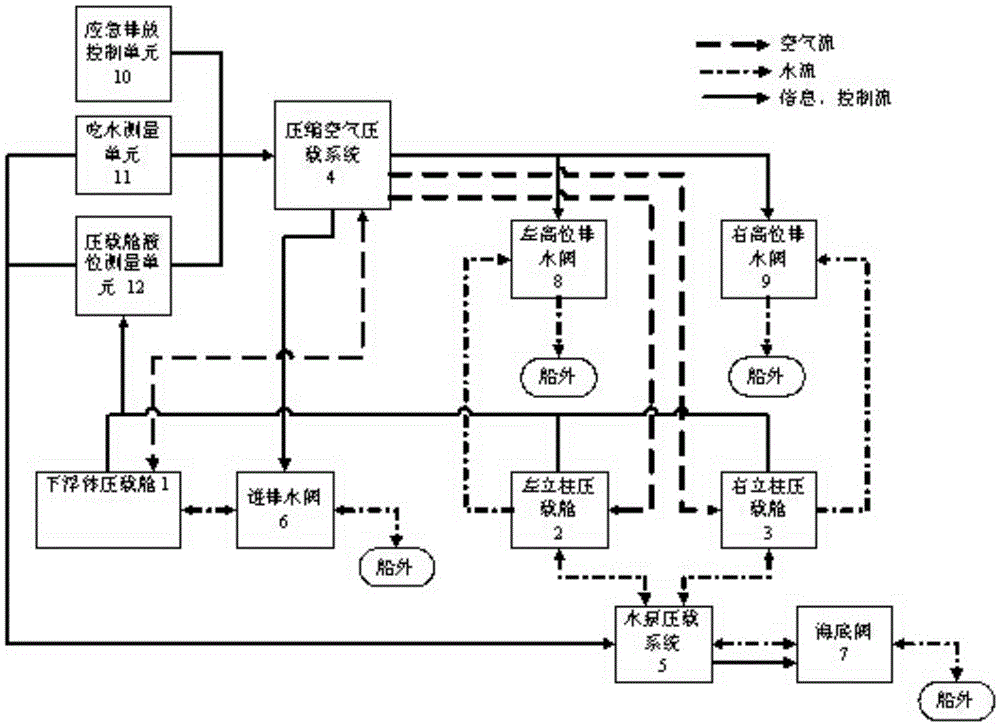

[0031] Embodiment 1: The ballasting / discharging operation process of the ballast tank of the lower floating body, such as image 3 shown.

[0032] When the semi-submersible lifting platform is converted under the conditions of dispatching navigation, lifting operation, and storm self-storage, it usually needs to quickly perform pressure / discharging operations to adjust the draft. When the platform needs rapid ballasting to increase the draft, the compressed air ballast system 4 is first started, and the air in the lower floating body ballast tank 1 is discharged through the pipe opening arranged at the top of the ballast tank 1 by means of the compressed air ballast system 4; then Open the inlet and outlet valves 6, and the water outside the ship enters the ballast tank 1 of the lower floating body from the inlet and outlet valves 6 by gravity; through the corresponding measurement of the ballast tank liquid level measurement unit 12 and the draft measurement unit 11, until the...

Embodiment 2

[0034] Embodiment 2: The ballasting / discharging operation process of column ballast tanks in non-emergency situations, such as Figure 4 shown.

[0035] When the semi-submersible lifting platform is converted under the working conditions of dispatching navigation, lifting operation, storm self-storage, etc., after the draught adjustment of the ballast tank 1 of the lower floating body is quickly carried out in the first embodiment, it is often It is also necessary to perform further ballasting / discharging operations on the column ballast tank of the platform to fine-tune the draft of the platform. When it is necessary to ballast the column ballast tank, first start the water pump ballast system 5; then open the seabed valve 7, and the water outside the ship is pumped into the ballast tank in the column through the water pump ballast system; through the ballast tank liquid level measurement Unit 12 measures until the required level is reached and the ballasting operation is co...

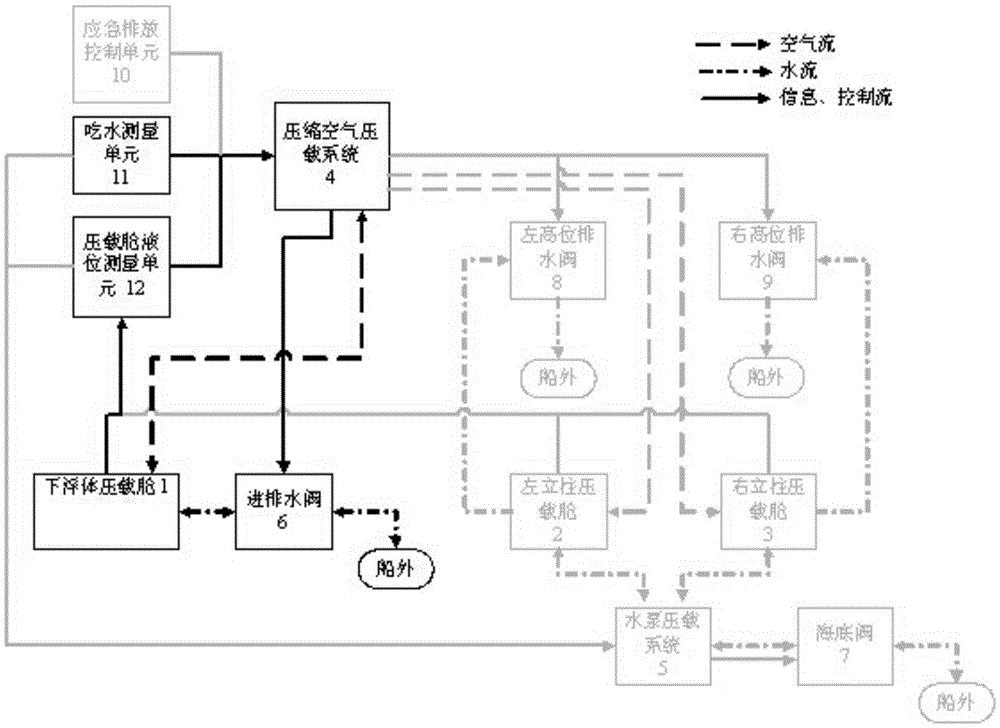

Embodiment 3

[0037] Embodiment 3: The anti-tilting load adjustment operation process of the column ballast tank under the lifting condition, such as Figure 5 shown.

[0038] During the lifting operation of the semi-submersible lifting platform, due to the rotation of the boom with heavy objects, a certain overturning moment will be generated on the platform. In order to maintain the balance of the platform, the ballast tank of the platform needs to be adjusted during the process. When the crane is carrying out the lifting operation on the port side, the water pump ballast system 5 is started, and the ballast water is pumped from the left column ballast tank 2 to the right column ballast tank 3 through the ballast pipeline, and the ballast tank liquid level measurement unit 12 is at the same time Measure until the required liquid level is reached, the load adjustment operation is completed; when the crane is performing lifting operations on the starboard side, the water pump ballast system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com