Experimental method for tensile property of steel wire rope coating material

A technology for coating materials and tensile properties, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of irregular fracture of coating materials, short service life of materials, etc., and achieve easy operation and simple experimental methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for testing the tensile properties of a steel wire rope coating material, comprising the steps of:

[0041] 1. Sample preparation: Make several samples of the coating material to be tested with a thickness of 1 mm, and set aside;

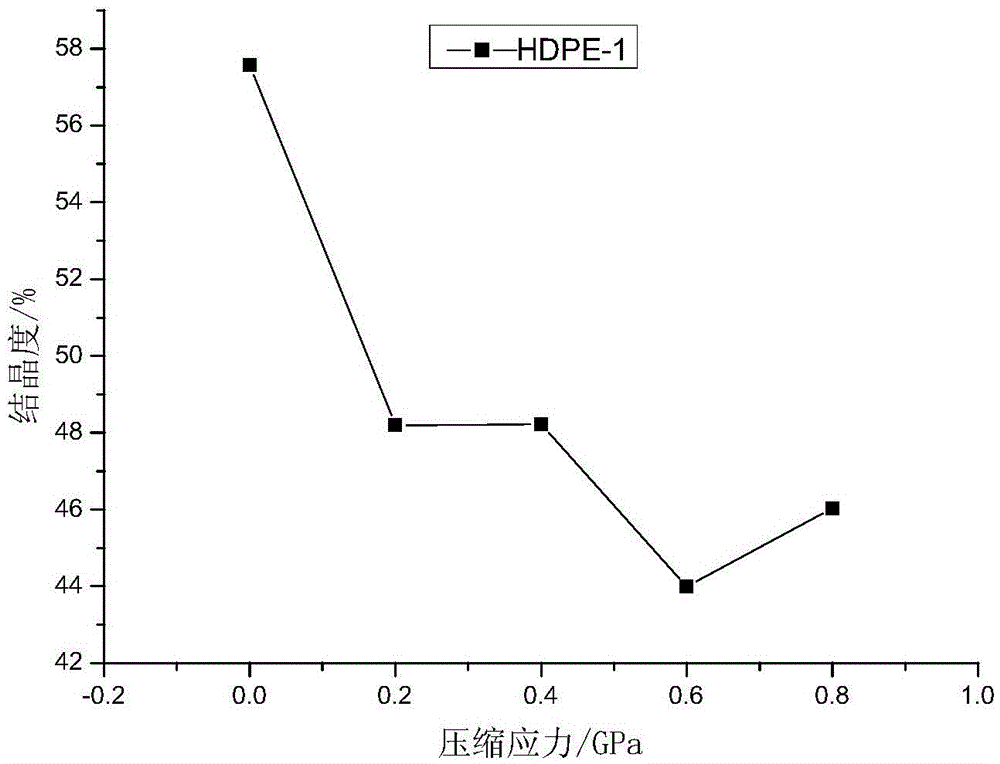

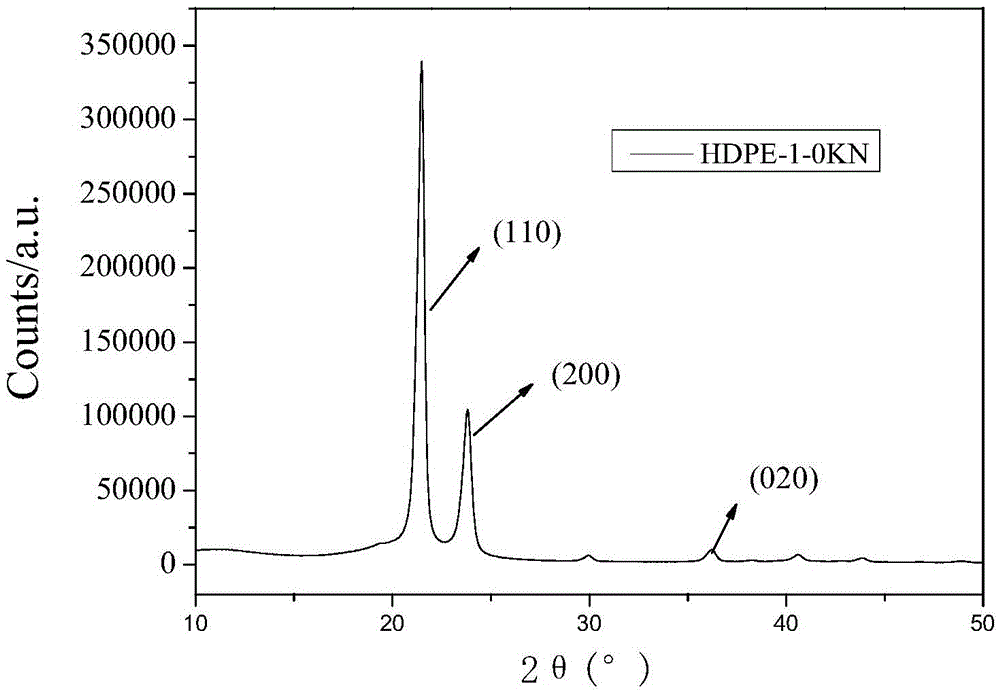

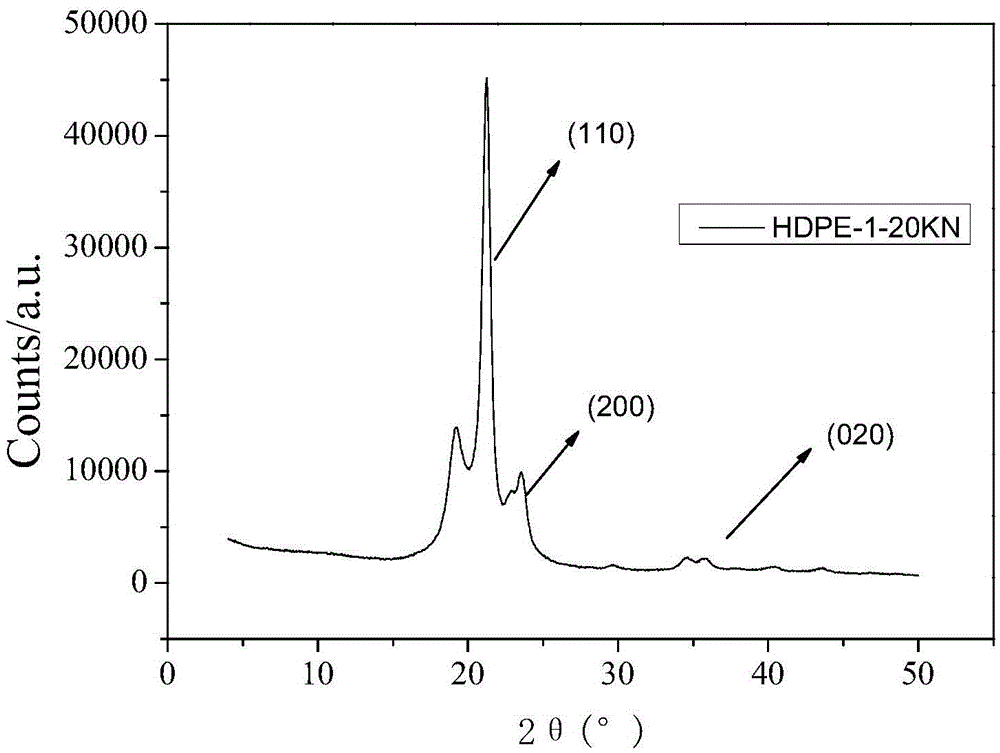

[0042] 2. Take the sample, and use the module to perform a bidirectional extrusion test on the middle part of the sample at a compression rate of 2mm / min. When the compressive stress increases to 0.2GPa, stop the extrusion, and compress the compressed sample at a rate of 50mm / min Biaxial tensile test is carried out on it at a high rate, the tensile strength and elongation at break are recorded, and the average value is taken as the test result after repeated testing for 5 times;

[0043] 3. Take the sample, and use the module to perform a bidirectional extrusion test on the middle part of the sample at a compression rate of 2mm / min. When the compressive stress increases to 0.4GPa, stop the extrusion, and compress the sample at a rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com