BGA package testing socket

A packaging testing and socket technology, which is applied in the direction of single semiconductor device testing, semiconductor/solid-state device testing/measurement, electrical measurement, etc., can solve problems such as unfavorable packaging and testing efficiency, increase staff work, etc., to reduce work intensity and improve the effect. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

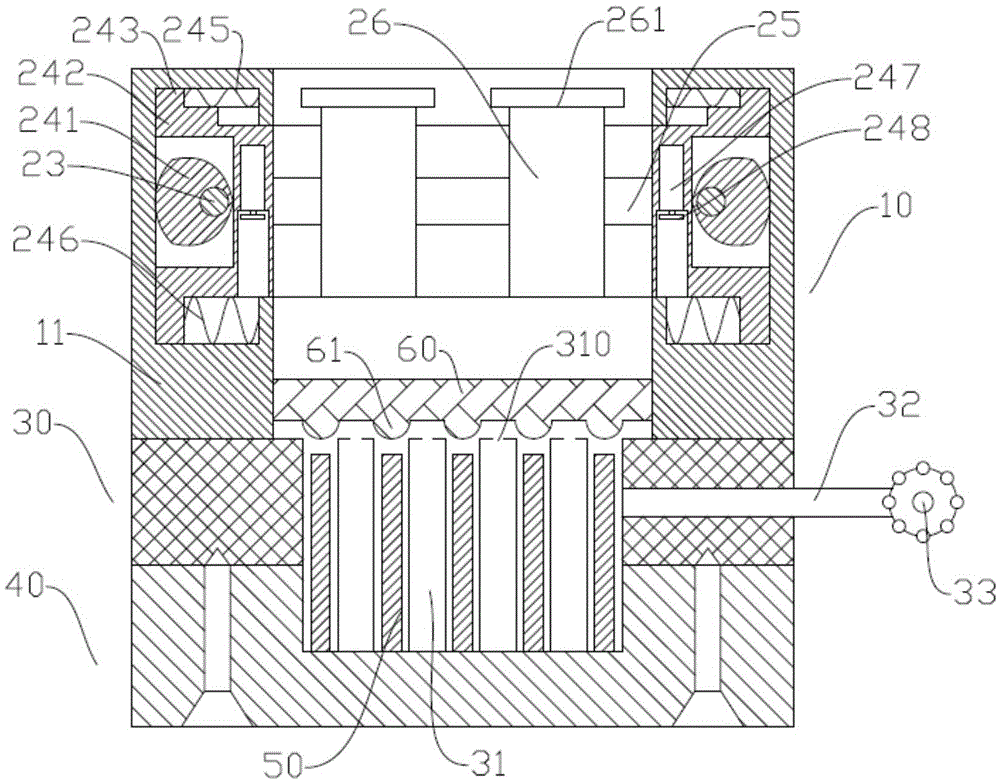

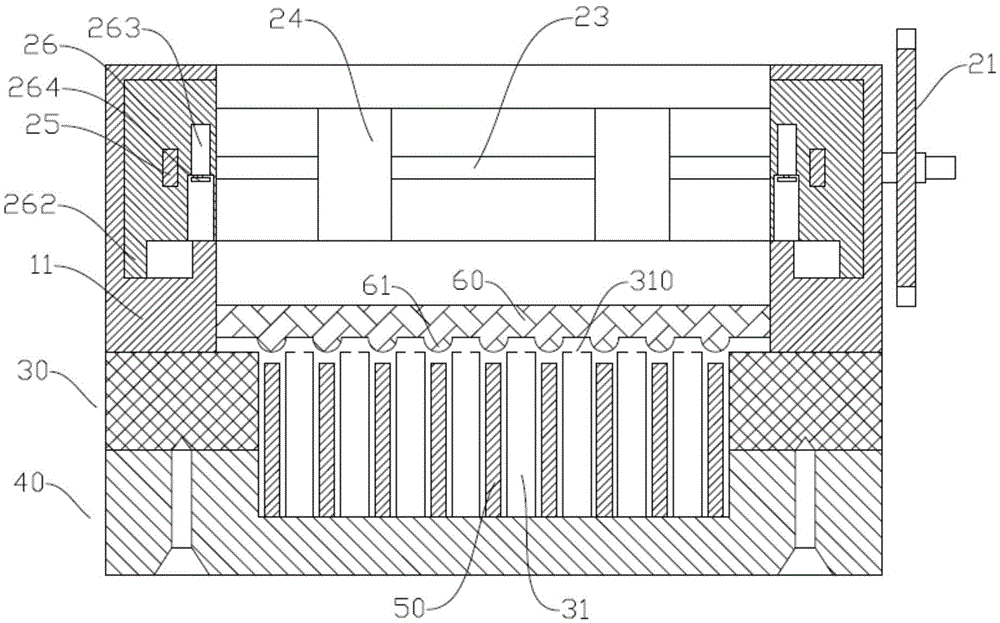

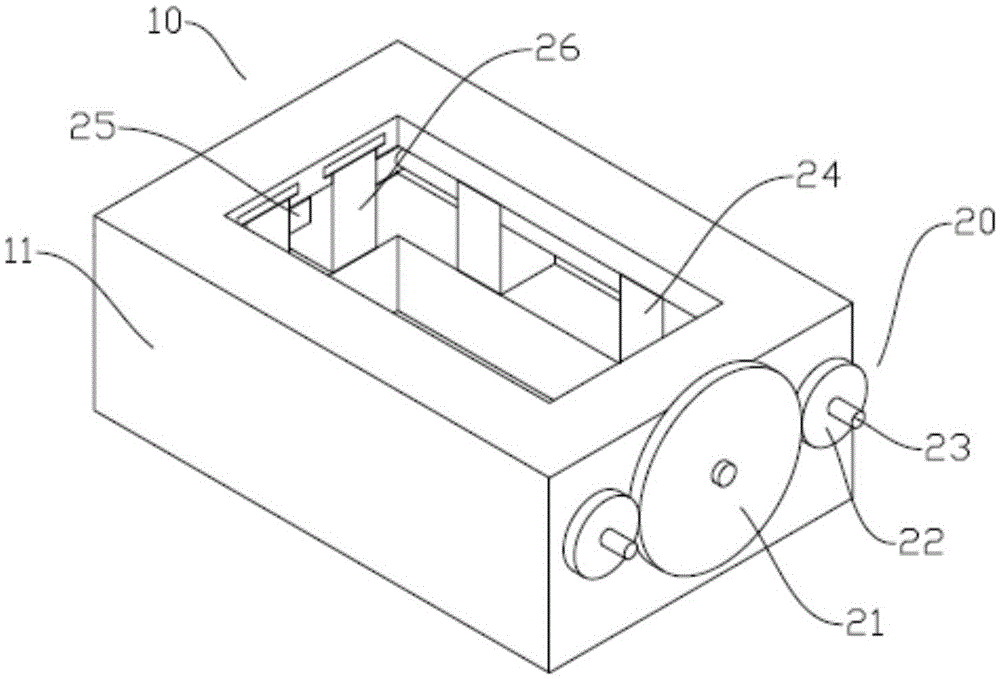

[0023] Such as figure 1 , figure 2 Shown, a kind of BGA package test socket, comprises the first support part 10 of fixing BGA package, the second support part 30 of supporting BGA package 60, the third support part 40 of fixing socket pin 50; The first support part 10 Be fixed on the second support member 30; The second support member 30 is fixed on the third support member 40; The first support member 10 and the second support member 30 are square frames; The BGA packaging test socket also includes the socket The pressure between the pin 50 and the BGA package 60 drops to a pressure relief device below the external pressure of the test socket; the pressure relief device includes an air cavity 31 arranged between the socket pin 50 and the BGA package, communicated with the air cavity 31 The pipeline 32 and the power unit 33 communicated with the pipeline 32; the air chamber 31 is distributed in the idle space between the socket needles 50, and an air hole 310 is provided ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com