transformer

A technology for transformers and reels, applied in the field of transformers, can solve the problems of poor coupling, smaller magnetic flux link area, and insulation damage, etc., and achieve the effect of good magnetic coupling and ensuring voltage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

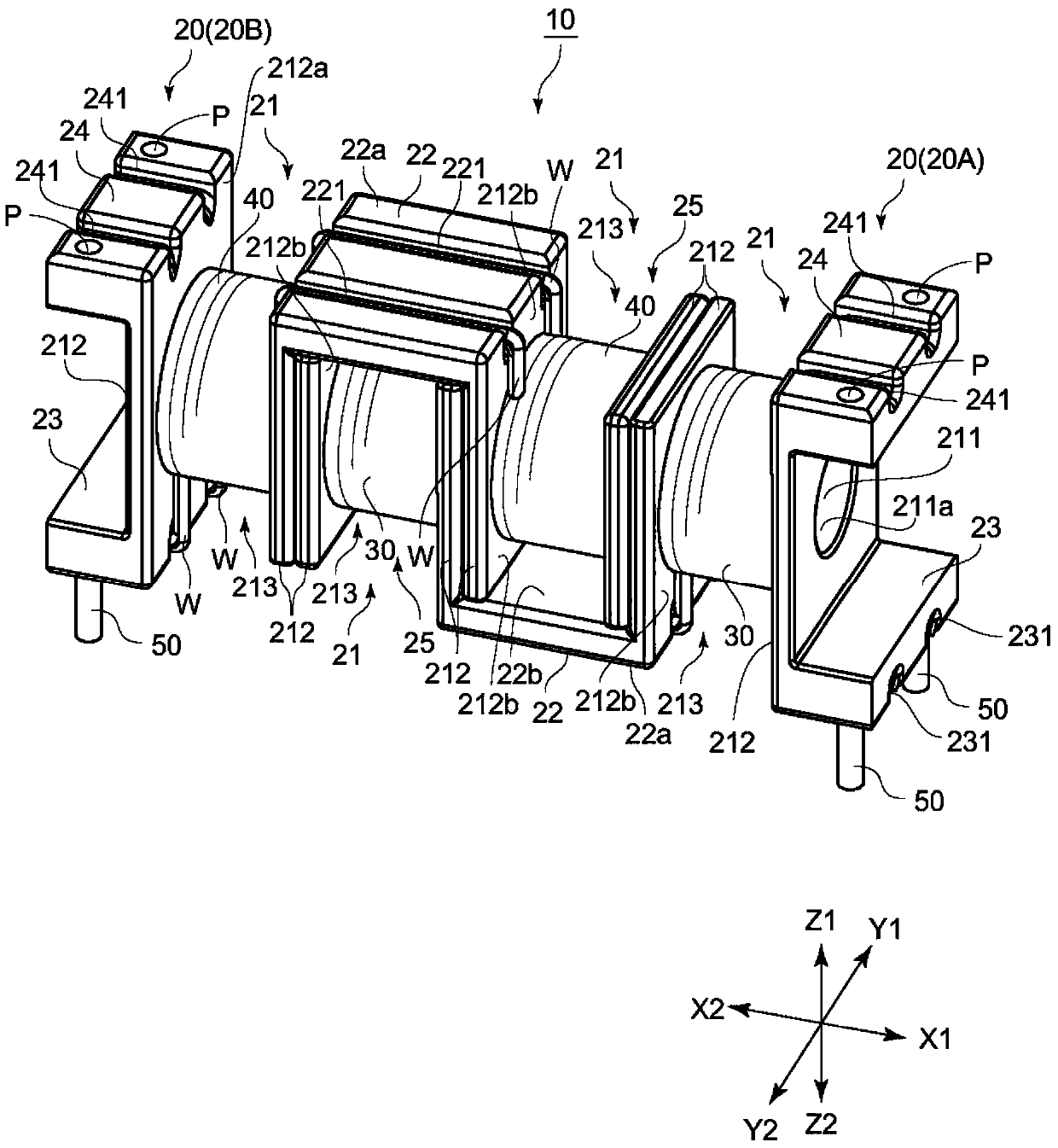

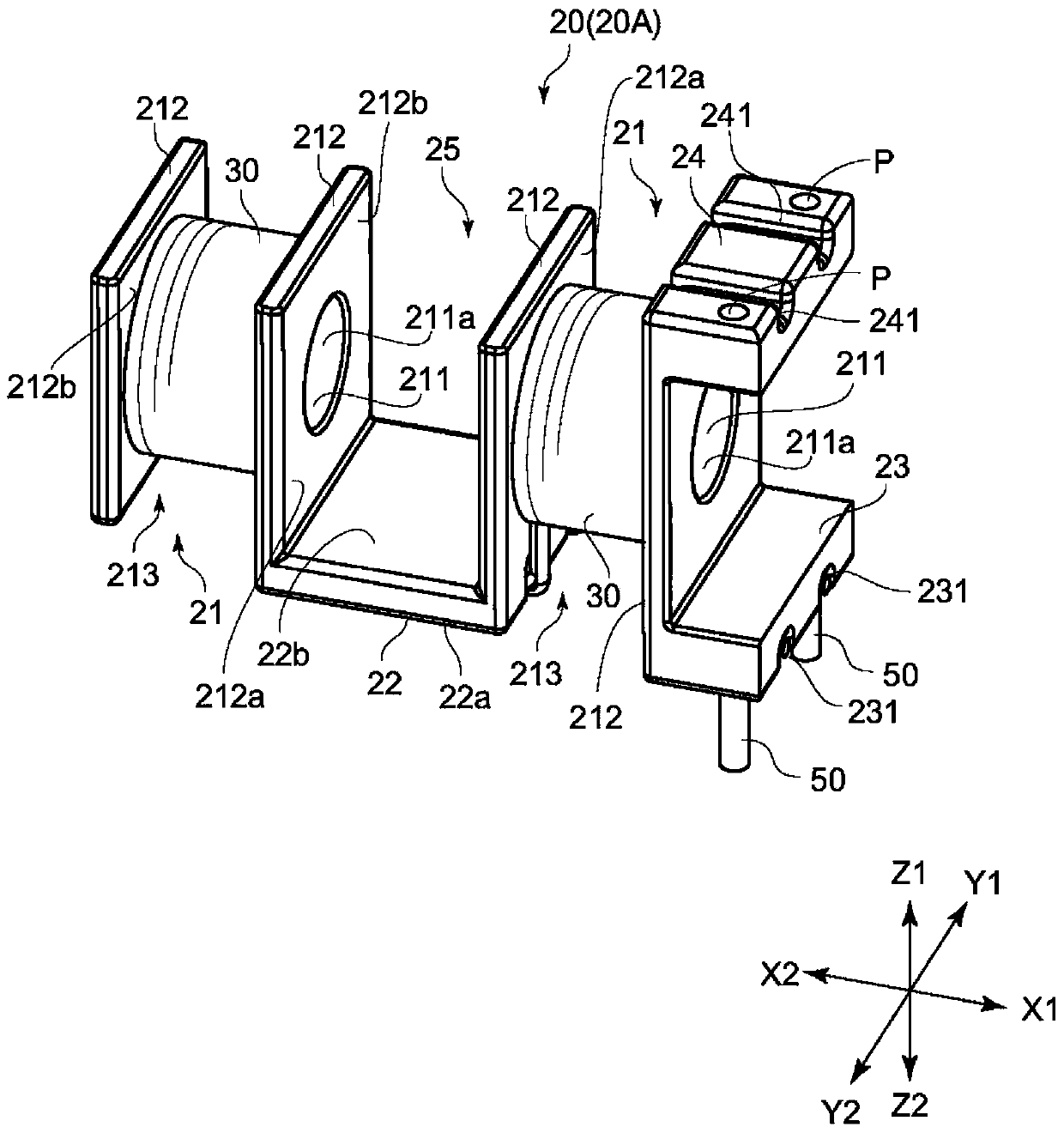

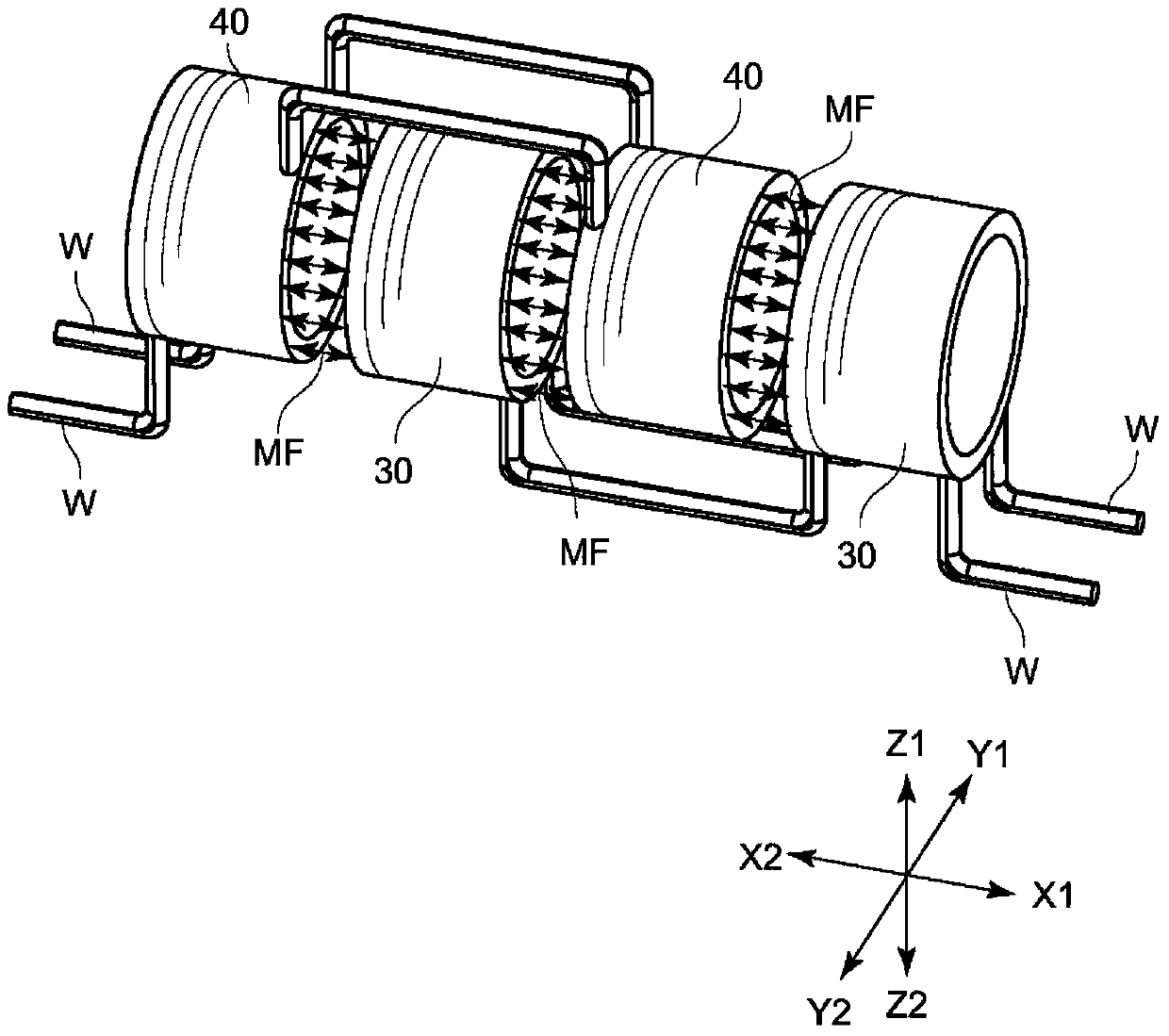

[0050] Hereinafter, the fitting type bobbin 10 used for the transformer 1 which concerns on one Embodiment of this invention is demonstrated based on drawing. In addition, in the following description, the first to third configuration examples of the fitting-type bobbin 10 will be described first, and then the transformer 1 using the fitting-type bobbin 10 will be described.

[0051] In addition, in the following description, the XYZ Cartesian coordinate system may be used for description, and the figure 1 The up-and-down direction in the diagram is referred to as the Z direction, and the protruding side of the connecting terminal 50 is referred to as the lower side (Z2 side), and the opposite side of the upper locking portion 24 is referred to as the upper side (Z1 side). In addition, let the axial direction of the fitted bobbin 10 be the X direction, and figure 1 The right side is defined as the X1 side, and the opposite left side is defined as the X2 side. Also, let the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com