Bur removing device of plastic sleeve

A plastic sleeve and deburring technology, which is applied in the field of stamping devices, can solve the problems of low pass rate, plastic sleeve cannot be sleeved on the outside of the terminal, and low production efficiency, so as to achieve extended service life and convenient and quick movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

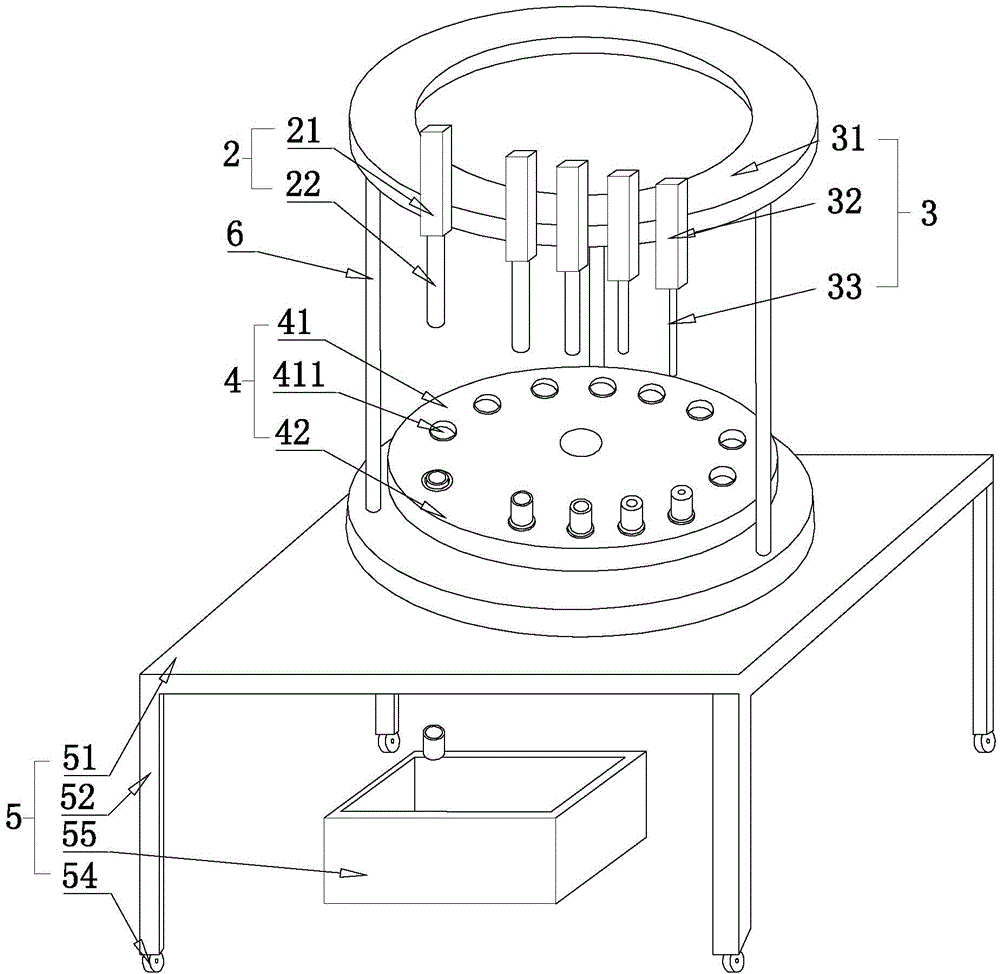

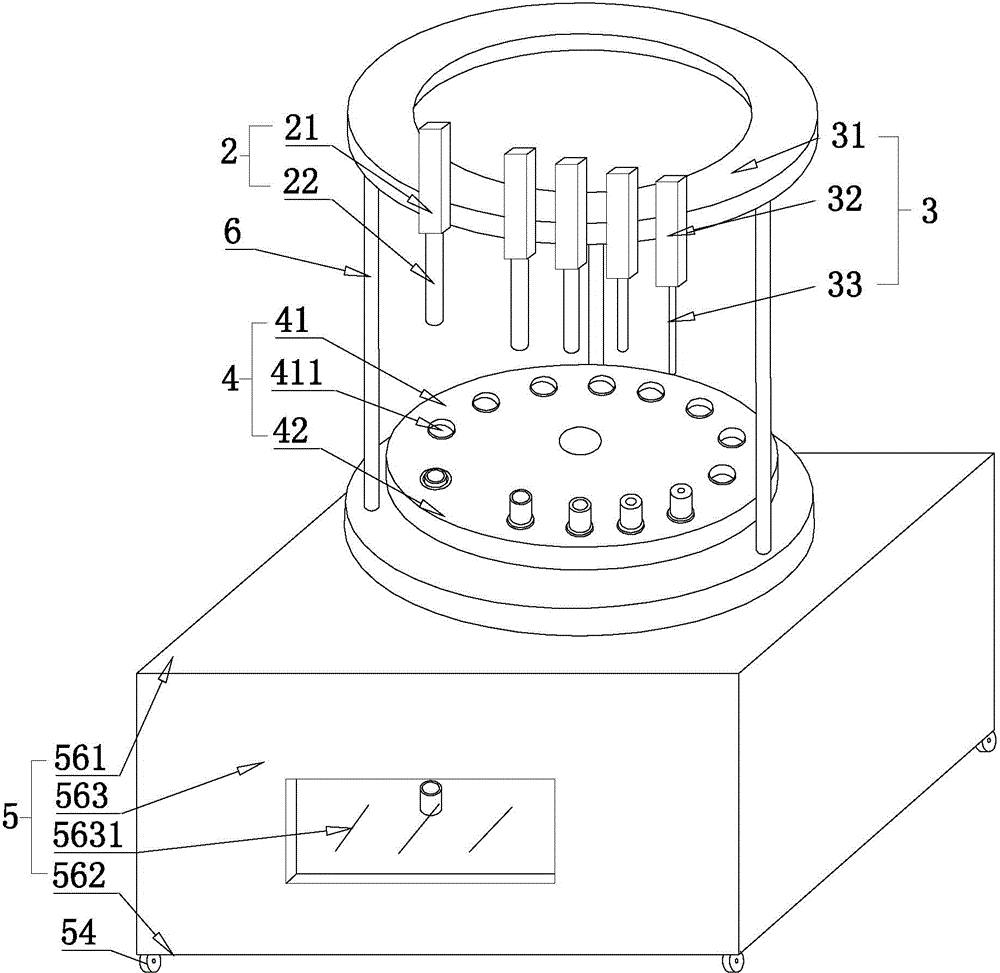

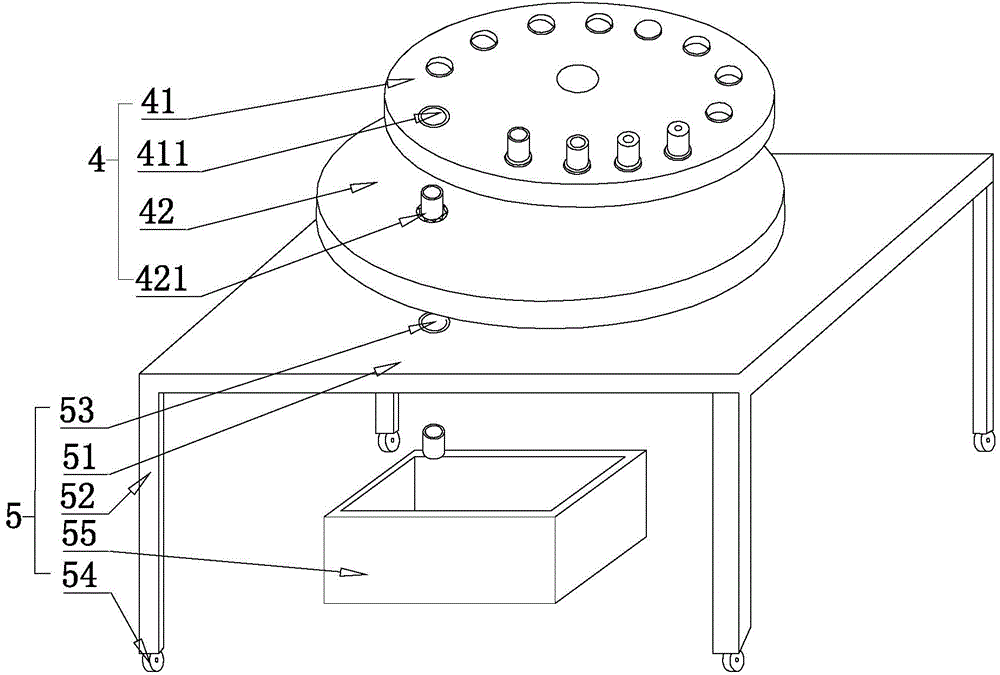

[0029] refer to Figure 1 to Figure 5 The embodiment of the plastic sleeve deburring device of the present invention will be further described.

[0030] A deburring device for a plastic sleeve 1, comprising a rotating mechanism 4 for placing the plastic sleeve 1, a stamping mechanism 3 arranged above the rotating mechanism 4, and a deburring mechanism 2, the rotating mechanism 4 includes a fixed plate 42 and a peripheral To the rotating disc 41, the fixed disc 42 is arranged on the opposite side of the rotating disc 41 relative to the stamping mechanism 3, and the upper circumference of the rotating disc 41 is distributed with fixing through holes 42 for fixing the plastic sleeve 1;

[0031] The stamping mechanism 3 includes an annular base 31, a number of stamping rods 33 for conflicting with the inner wall of the plastic sleeve 1, a stamping drive device 32 fixed on the annular base 31 for driving the stamping rods 33 to sit up and down, and for connecting The connecting co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap