Sesame cleaning, screening, separating and soaking device and sesame processing method

A technology of sesame and soaking tank, which is applied in the field of sesame washing, screening, separating and soaking devices and sesame processing, which can solve the problems of ignoring the wetting process, damaging the seed coat, and affecting the oil yield, so as to prevent damage, reduce friction, increase The effect of full exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment, further illustrate the present invention.

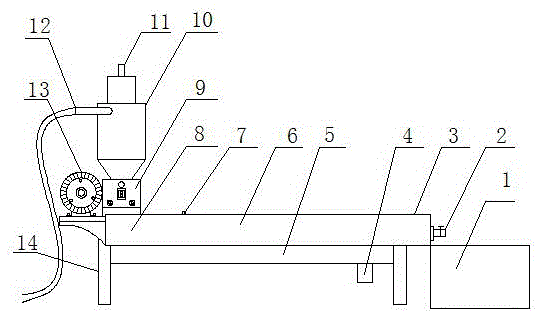

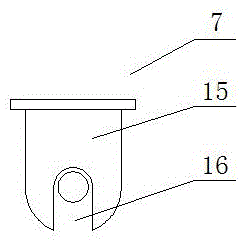

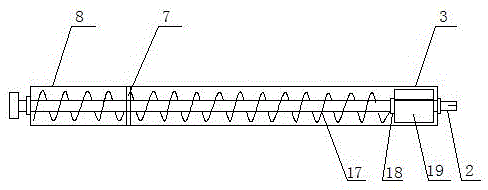

[0035] see figure 1 , image 3 It can be seen that a kind of sesame cleaning, screening, separation and soaking device of the present invention is composed of a cyclone separator 10 and a separation soaking tank; The discharge port 11 of the separator 10 is connected by a pipeline, and the feed port 12 of the cyclone separator 10 is connected with the material box by a feed pipe; the separation soaking tank is provided with a feeding screw 17, and the feed end 8 of the separation soaking tank is arranged There is a material speed regulating plate 7, and the discharge end 3 of the separation soaking tank is provided with a discharge device and a slag discharge port 4, and the discharge device is provided with a discharge pipe 18, and one end of the discharge pipe 18 is connected with the feeding screw 17, and the discharge pipe The other end of 18 is used as discharge port 2, and discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com