a juicer

The technology of a juice extractor and a transmission mechanism is applied in the field of fruit and vegetable juice extraction devices, which can solve the problems of difficulty in cleaning, a decrease in the juice yield, and the destruction of the nutrient components of the juice, so as to avoid cleaning and cleaning, high juice yield, and fast juice extraction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

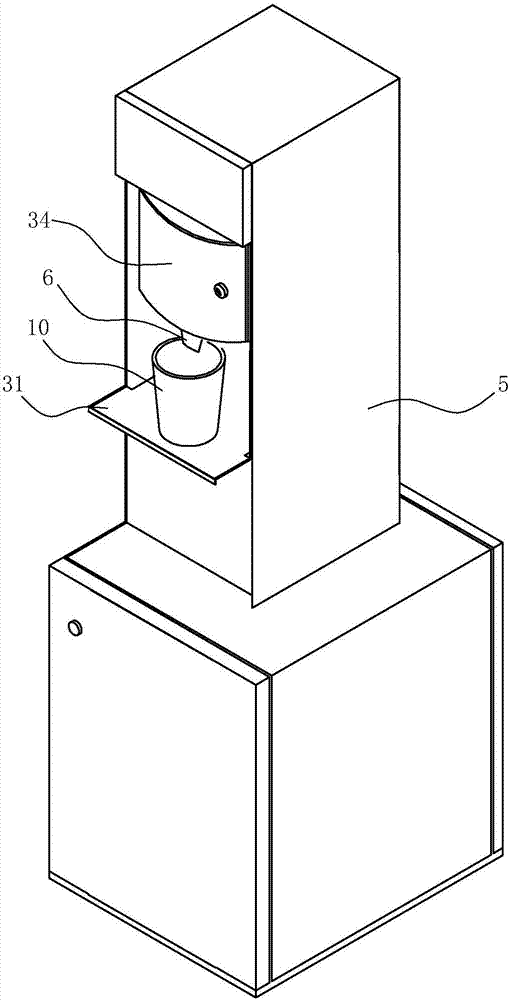

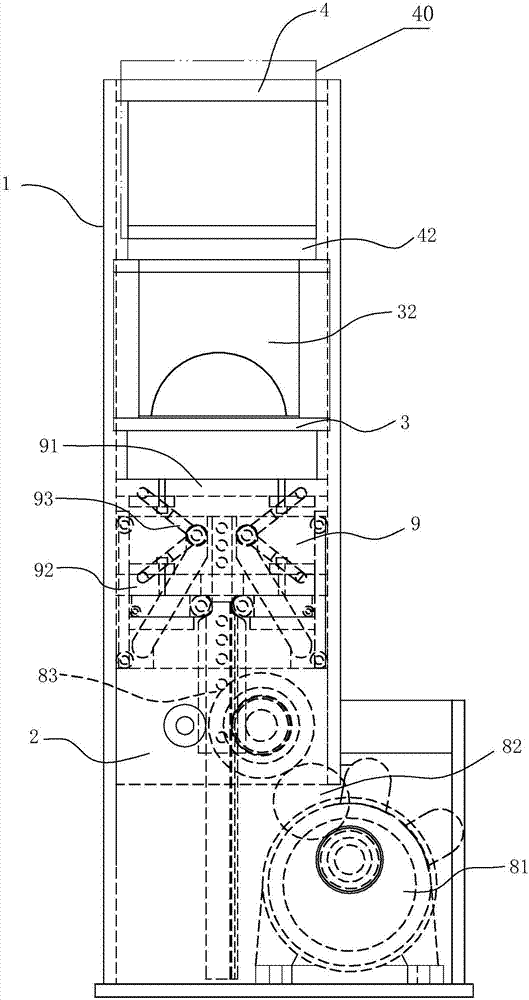

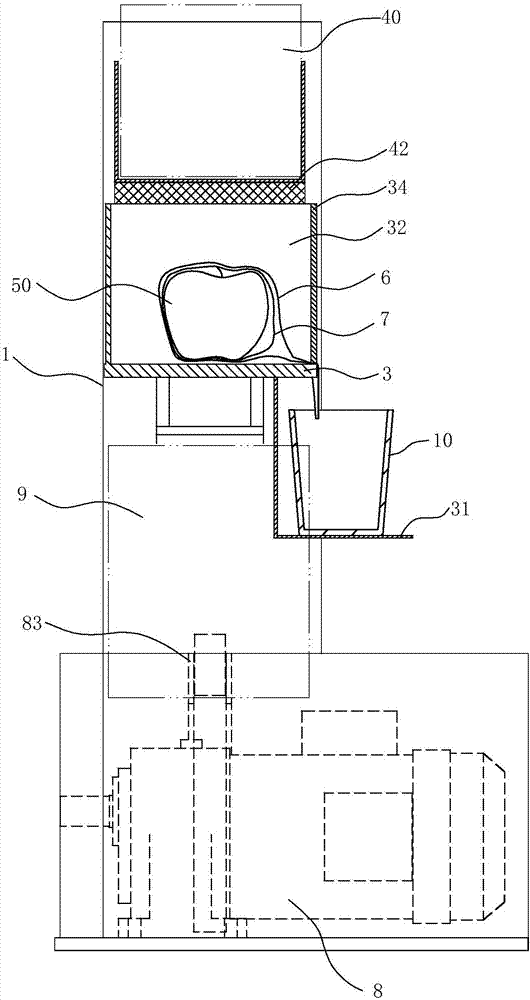

[0038] Such as Figure 1-4 As shown, the juice extractor of the embodiment of the present invention includes a vertically arranged support 1, and the support 1 is loaded with a lower beam 2 arranged horizontally at intervals, a moving beam 3 and an upper beam 4, and the upper beam 4 and the lower beam 2 are fixed on the support. 1, a driving device 8 is also provided in the bracket 1, and the driving device 8 is used to drive the moving beam 3 to slide and lift between the lower beam 2 and the upper beam 4. The outside of the bracket 1 is covered with a shell 5 . The front side above the moving beam 3 protrudes from the outside of the bracket 1. The front side is a cup table 31 for placing the juice collection cup 10. The middle and rear part of the moving beam 3 is provided with a platform higher than the cup table 31 as a pressing table. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com