Dry type electrostatic processing device for haze

An electrostatic treatment and dry technology, applied in the field of haze dry electrostatic treatment device, can solve the problems of complex structure of dust removal device, high production and operation cost, difficult installation and maintenance, etc. , the effect of not occupying the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

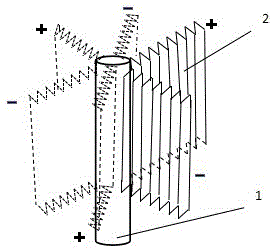

[0019] Such as figure 2 As shown, the smog dry electrostatic treatment device includes a cylinder 1 and 6 adsorption panels 2 arranged in pairs, and the adsorption panel 2 is arranged on the cylinder 1 along the radial direction of the bottom surface of the cylinder 1; the adsorption panel 2 It is a conductor, and the surface is covered with an insulating film; the cross-section of the adsorption panel 2 is in a zigzag shape, and the angle at the bend is 60°; the adsorption panel 2 is connected to a direct current with a voltage of 36V, and the adjacent adsorption panels 2 are connected to positive and negative phases; The panel 2 is insulated from the column 1 and the ground respectively.

[0020] Through the existing rectification equipment on the market, the alternating current is rectified into direct current. After the direct current is connected, the smog dry electrostatic treatment device starts to work. According to the principle of electrostatic adsorption, the paire...

Embodiment 2

[0022] Except for the use of 24V direct current, the other settings of the haze dry electrostatic treatment device are exactly the same as those described in Example 1. In a room with an area of 20 square meters and a height of 2.7 meters to simulate the smog environment, the device was placed in the middle of the room, and the smog environment was basically improved in about 2 hours. The surface of the 6 adsorption panels adsorbed a layer of dust particles, and the dust particles absorbed were slightly inferior. The adsorption effect in Example 1.

Embodiment 3

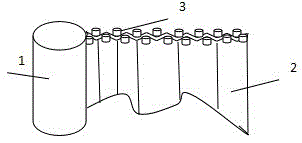

[0024] Such as figure 2 with image 3 As shown, the smog dry electrostatic treatment device is completely consistent with the device described in Example 1, and a water spray hole 3 is installed on the top of the adsorption panel 2 . When the dust particles on the surface of the adsorption panel 2 are absorbed too much, the surface of the adsorption panel 2 can be rinsed by spraying water from the water spray hole 3 through manual or intelligent control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com